As the title says, why should i switch mid way through a project and use EMC...

Give me a few good reasons.

Thread: Why should i use EMC over Mach3

Results 1 to 20 of 148

-

12-10-2011, 05:54 AM #1

Registered

Registered

- Join Date

- Feb 2006

- Posts

- 123

Why should i use EMC over Mach3

-

12-10-2011, 12:13 PM #2

Registered

Registered

- Join Date

- Nov 2004

- Posts

- 23

Well, there are plenty of reasons you might choose EMC over Mach 3, depending on what you are doing.

From what I remember of the last time I used it, Mach 3 is basically a complete hobbyist level controller. It gives most hobbyists with basic machines the features they want right out of the box. It is built from the ground up for this. It may also work well for low end production machines.

EMC is a realtime industrial CNC controller that happens to include some basic UIs and stuff suitable for hobby use. It is based on rcslib and GNU/Linux/RTAI, which are used to control all sorts of robotic equipment, including things that are WAY outside of the typical hobbyist or even professional machine shop range.

So in terms of high end capability and overall flexibility, EMC wins hands down. Mach3 doesn't even really compete with it. If you wanted, you could run a large assembly line with EMC (this is part of what rcslib was originally designed to do). The downside is that you need to do a significant amount of work in these cases.

If you are using a basic 3 axis stepper controlled mill or lathe and don't want to go beyond that configuration, they both work fine. Mach 3 has a fancier UI than any of the ones that currently come with EMC if you care about that.

Since EMC is realtime, you can often run into hardware interrupt issues that cause latency problems. This means it may not run well on many computers. On the other hand, this allows you to close servo loops and stuff on the computer, and get much more accurate timing.

EMC is convenient if you already use Linux. It is libre, which is a very significant benefit to integrators and those who can write software. It is also gratis, though that probably isn't a significant consideration considering the cost of the machines it controls.

EMC2 gets really nice when you have a more complex machine, or want to modify or add to the software. It offers many more possibilities in that respect.

Personally, I use EMC because:

- Except for gaming, I use Linux almost exclusively for work and home use, so I find it easier to use

- I'm interested in building some fairly complex machines in the future and don't want to be limited to specific kinematics or control features

- I use rcslib at work

- I like the modification potential it offers

If you are thinking of switching to EMC, you can download a live CD and try it out. You may find you just like it better.

-

12-10-2011, 01:38 PM #3

Registered

Registered

- Join Date

- May 2005

- Posts

- 1662

For a stepper driven machine there may be no compelling reason. Mach3 does the job, the size of the user base is proof enough.

Mach3 and emc2 take a different approach to servos. EMC2 can use what's been described as the 'smart software--dumb hardware' approach. Mach3 itself is step/direction only and passes control over to the hardware ?? Others can explain this fully. I've only begun exploring closed loop systems and possibly mixing up some concepts.Anyone who says "It only goes together one way" has no imagination.

-

12-10-2011, 02:20 PM #4

Community Moderator

Community Moderator

- Join Date

- Mar 2003

- Posts

- 35538

1) You don't have, or don't want to spend $175As the title says, why should i switch mid way through a project and use EMC...

Give me a few good reasons.

2) You already use Linux. or are one of those that hate Windows and all things microsoft.

3)You need one of the features that EMC has that Mach3 doesn't, like the kinematics or software closed loop.

Unless you're going to give specific examples, this is really not a fair statement.

For a 3 axis mill or router, Mach3 is probably every bit as configurable and customizable as EMC. and in some ways, even more so (custom screens for one).

Sure, if you're building some other type of machine, then EMC may win in some cases, But there are many other types if machines being controlled by Mach3 besides routers and mills.Gerry

UCCNC 2017 Screenset

http://www.thecncwoodworker.com/2017.html

Mach3 2010 Screenset

http://www.thecncwoodworker.com/2010.html

JointCAM - CNC Dovetails & Box Joints

http://www.g-forcecnc.com/jointcam.html

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

12-10-2011, 08:51 PM #5

Registered

Registered

- Join Date

- Nov 2004

- Posts

- 23

By more complex machine, I mean something beyond a simple standalone machine tool with cartesian axes.

I would say there are far more options to customize the UI on EMC. You can really create whatever kind of UI you want, including anything Mach3 can do. That's any kind of UI, not just GUI or screen layout. You could have a control panel that mixes 5 different touch screen monitors with a bunch of physical controls if you wanted, all directly connected to EMC (not just a touch screen computer that can send commands to it). Sure, it takes more effort but it is very possible.For a 3 axis mill or router, Mach3 is probably every bit as configurable and customizable as EMC. and in some ways, even more so (custom screens for one).

With EMC, if it doesn't do something out of the box, you can add that support (or pay someone to).

On a standalone machine tool, this can be very nice, but you can also go far beyond that.

As an arbitrary example of high end capability, lets say I need to build a machine which makes hard drives (this may not reflect the real process). I get the unfinished cast aluminum chassis, cover plate, the circuit boards, the spindle motor, head assembly and related components, and the platters and mounting hardware in on separate conveyors. I can use a 4 axis SCARA arm running EMC and some machine vision software to load the incoming components.

The chassis is painted and dried, then loaded into a 5 axis mill running EMC for finishing.

A VME cage running vxworks and rcslib controls a machine which writes the servo tracks onto the platters using laser interferometer position feedback processed through a custom FPGA card.

One or more 6 axis arms controlled with EMC install the remaining components in the drive and send it on to a testing station. All of these machines communicate with a supervisory controller over NML that coordinates their operations. There may be several hundred GPIO lines and an additional 10+ arbitrary servo controlled axes involved here.

I could then build a single operator console for the whole system with whatever displays I need. I can show the actual status of the whole system with closed loop feedback.

You could use Mach 3 in part of such a system. It could run the 5 axis mill and you can use PLCs and other controllers for everything else. You might be able to force it to work elsewhere, but there wouldn't be much point.

EMC and the underlying rcslib are designed for this type of thing. You can run that entire system with controllers based on EMC, or at least rcslib. There may be several controllers, but it can all run as one coordinated system.

-

12-10-2011, 09:57 PM #6

Member

Member

- Join Date

- Oct 2005

- Posts

- 4230

most guys who have cnc's at home only build 3 or 4 axis machines though there are a number of 5 axis being built as well .

I used emc for a good while , but on the machine that i have now I had to stop using emc because it couldn't push my stepper motors as fast as I could push them with mach , I tried lots of tweaks and the pc would freeze up if i pushed things too far . Ubuntu was far too much of a resource hog which needs a much more powerful pc to run than xp . I use a p4 for my setup but I've run mach on p2 pc's without any problems what so ever , even though it is recommended for a larger pc ,

Mach has a much cleaner interface and more professional look that i find feels closer to using professional machine controls such as fanuc or what ever , especially with the use of my touch screen , plus its dead easy to customize the look and feel to suit my needs .

I'm not knocking emc because its good for what it is but when I used it the documentation was lacking and in my pinion so was the softwareA poet knows no boundary yet he is bound to the boundaries of ones own mind !! ........

-

12-10-2011, 11:07 PM #7

Registered

Registered

- Join Date

- Jul 2003

- Posts

- 1754

(I am an emc2 advocate...)

I think it really depends on the project. I am sure for a step/direction machine that has a few home/limit switches and spindle control - both work just fine. From what I hear - mach probably can put out a higher pulse frequency than emc. Emc is going to top out at 40 to 50khz on good hardware.

With emc2 though - you have quite a few options. (inexpensive options.) For around $89 you can get an interface card that gives you 48 digital i/o. This will do very fast encoder counting, very fast step generation, high frequency pwm, and i/o. This can also do closed loop servos. (closed loop within emc) (analog interface is a daughter board but still around $100). So if you need faster step generation - hardware step generation is pretty inexpensive.

Emc can also do some pretty cool stuff right out of the box..

-rigid tapping (I have seen rigid tapping done with just printer ports) (not having to use the spindle as an axis - emc gears the axis to the spindle encoder)

-Very accurate lathe threading - you can use a quadrature encoder + index to track the spindle very accurately.

-Realtime OS (very stable timing.)

-Integrated ladder logic

From there you can get as deep as you want. I Converted a Kearney and Trecker NC mill from the late 60's. This machine has a 60 tool chain, pallet system, 16 speed spindle, and all the bells and whistles.

You can read about it here.

Large Kearney & Trecker HMC conversion. - CNCzone.com-The Largest Machinist Community on the net!

I have around $600 in the interface hardware. That gave me 10 analog axis, differential/ttl encoder interfaces plus 96i/o. (mesa hardware) A steel if you ask me. everything is controlled by emc and its ladder logic. I cannot say enough good about it. I now just added spindle temperature compensation. As the spindle heats up - it grows. So I offset the z axis to compinsate.

sam

-

12-10-2011, 11:27 PM #8

Registered

Registered

- Join Date

- Jul 2003

- Posts

- 1754

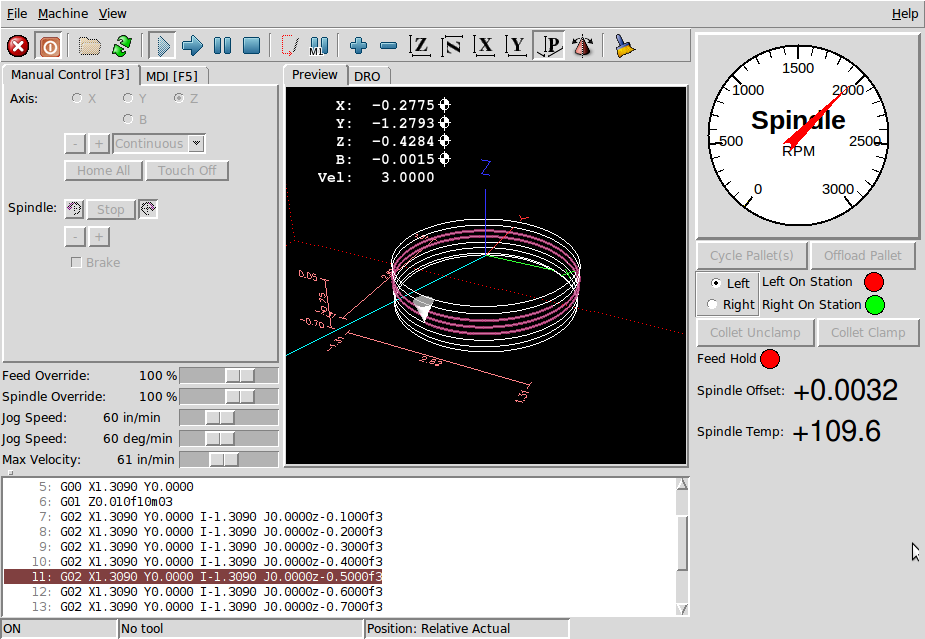

as far as screen editing.. You will have to be a programmer to change the existing screens.

But...

You can add 'panels' that are generated by xml.. (there is also a new way to do it using glade - but I have not played with that.)

You can see the panel on the right that I added (and the spindle temp and offset)

-

12-11-2011, 03:59 AM #9

Registered

Registered

- Join Date

- Feb 2006

- Posts

- 123

Good stuff guys, now here is where I stand. I have been servicing and rebuilding CNC machines for over 35years mainly on the mechanical side, my buddy is a fanuc engineer so he takes care of the electronics although quite a bit has rubbed of on me over the years. All the CNC machines from the 80's would be analog +-10v then later digital, so I started looking for a control to retro-fit onto those old but good drives and motors. I was not to well up on the step/dir or PWM so went ahead with the mach3 anyway. I had a knee mill with a baffed out Fagor, Dc brushed servo motors and drives, kept the servos and motors but now I need a motion control and that was a $1000.00 DSPMC from Vital systems but found and still find there are some conflicts between mach and the motion board. I have spent a lot of time and effort putting it through it's paces and it works great but I just know if it's stable enough to put it out for general use in the industry. Now I'm looking at EMC2 but find it doesn't have +-10v analog for the drives either, but step/dir and PWM, do I still have to buy the motion board? don't want to use steppers and go backwards and don't want to load of money on state of the art drives and motors. I feel like a'm going around in circles.

ray.

-

12-11-2011, 04:08 AM #10

Registered

Registered

- Join Date

- Jul 2003

- Posts

- 1754

there are at least 3 suppliers that have +/-10v hardware that work with emc2. Mesa, Pico systems, vital systems.. In that order of popularity IMHO. What sucks is I would guess the motion board you bought from vital systems isn't supported by emc. (emc doesn't want or need a 'motion' board.) but the hardware is quite a bit cheaper because of that.

http://wiki.linuxcnc.org/cgi-bin/emc...orted_Hardware

I am using mesa hardware with their analog daughter boards.

sam

-

12-11-2011, 04:15 AM #11CNC, Mechatronics Integration and Custom Machine Design

“Logic will get you from A to B. Imagination will take you everywhere.”

Albert E.

-

12-11-2011, 05:14 AM #12

Registered

Registered

- Join Date

- Feb 2006

- Posts

- 123

Here is where we all get confused, well I do. talked to pico systems and he only supports EMC2 and he said his drives are PWM and will not drive fanuc motos. Vital systems has a motion board for EMC2 for $500.00 so I guess that's PWM.

No Al, i haven't looked at them yet, what do you think Al?

This all started because when I got down to the short strokes testing Mach3 running the wizards, I found when I was running a wizard and then went to look at that wizard screen to check the parameters that I had set, the machine jumped about 1/2" and snapped my 1/2" end mill, when I posted it I got answers like well what do expect from $159.00 software....

Ray.

-

12-11-2011, 05:26 AM #13

From what I have seen so far it seems very impressive, once I get this current project out of the way, I am looking for a system to build into a Panel PC system for compactness.

So far Dynomotion is ahead and the support seems A1.

Al.CNC, Mechatronics Integration and Custom Machine Design

“Logic will get you from A to B. Imagination will take you everywhere.”

Albert E.

-

12-11-2011, 05:36 AM #14

Registered

Registered

- Join Date

- Feb 2006

- Posts

- 123

Sorry Al, I should have said what do think of Mach3 vs EMC.

Still trying to find out where the dynomotion puts out +- 10volts for my Fanuc motors.

Ray.

-

12-11-2011, 05:40 AM #15

Registered

Registered

- Join Date

- Feb 2006

- Posts

- 123

Do I read correct, Dynomotion puts out 80V, my Fanuc require 180v.

-

12-11-2011, 05:51 AM #16

Kanalog add-on for ±10vdc drives.

Or without it for step/dir.

IIRC you have AC redcap you were hoping to use with Granite drives to bypass the Fanuc comm pulses?

If so those drives are step/dir? If you want to use the Fanuc red cap with ±10vdc drives without changing the encoders you would need one of the commutation pulse convertors such as the one by J. Elson.

Dynomotion will work with any supply voltage step/dir or analogue drives, not necessary to use the SnapAmp..

Al.CNC, Mechatronics Integration and Custom Machine Design

“Logic will get you from A to B. Imagination will take you everywhere.”

Albert E.

-

12-11-2011, 06:03 AM #17

Registered

Registered

- Join Date

- Feb 2006

- Posts

- 123

Still waiting to hear from Granite. I do have Fanuc motors with Ab, encoders and I have some red caps with Inc, encoders.

So EMC or Mach3, or that putting you on the spot...

-

12-11-2011, 06:08 AM #18

The systems I have built so far involve Galil Motion cards so I have not used EMC at all, although I looked at it some time ago.

Mach I have played with it in an experimental fashion but not in practical use.

The thing that attracts me to the Dynomotion is it seems the closest to the Galil systems for performance.

Al.CNC, Mechatronics Integration and Custom Machine Design

“Logic will get you from A to B. Imagination will take you everywhere.”

Albert E.

-

12-11-2011, 06:13 AM #19

Registered

Registered

- Join Date

- Feb 2006

- Posts

- 123

The Vital unit is a little expensive but I didn't have to do any programming just setting up and that fun and games, would the dynomotion be the same, I don't know any VB C+.

-

12-11-2011, 09:12 AM #20

Registered

Registered

- Join Date

- Nov 2005

- Posts

- 496

Are you only interested in the stability of the hardware/software ?

EMC and Mach have a completely different look and I believe their g code dialect is slightly different.

supported features are different or realized in a fundamentally different way.

What features are important to you?

do you need a custom looking screen?

do you need rigid tapping capability?

do you want to be able to change or upgrade features in the future?

Do you mind being locked in (somewhat) to the features of a 'smart' motion card or prefer to use a cheaper more general card that could have it's capabilities changed by upgrading firmware.

Do you mind spending time on the project to get it the way you want?

Is using a windows OS important to your customers?

There is so many reasons for using either program.

Similar Threads

-

Mach3

By boggy1995 in forum CNC (Mill / Lathe) Control Software (NC)Replies: 3Last Post: 05-02-2012, 10:04 PM -

Differences Between Mach3 Mill and Mach3 Plasma?

By cjjonesarmory in forum Mach Plasma / LaserReplies: 0Last Post: 11-18-2010, 04:12 PM -

Using Mach3 with Reprap extruderUsing Mach3 with Reprap extruder

By router101 in forum CNC (Mill / Lathe) Control Software (NC)Replies: 3Last Post: 11-03-2010, 10:46 PM -

4to eje con mach3

By dansa0561 in forum SpanishReplies: 3Last Post: 07-31-2008, 04:44 PM -

Mach3

By butchw in forum Mach MillReplies: 7Last Post: 02-29-2008, 03:50 PM

Reply With Quote

Reply With Quote