I had read somewhere about a torch head being retained by earth magnets and mounted as a break-away fixture. It would be easy to attach a micro switch to the mount to trigger an emergency stop. Have you heard of this before? I wish I could find the site that talked about it, now...

Thread: New Build Questions

Results 21 to 31 of 31

-

01-10-2012, 05:03 PM #21

Registered

Registered

- Join Date

- Dec 2011

- Posts

- 81

-

01-10-2012, 05:04 PM #22

Registered

Registered

- Join Date

- Dec 2011

- Posts

- 81

-

01-10-2012, 06:00 PM #23

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 303

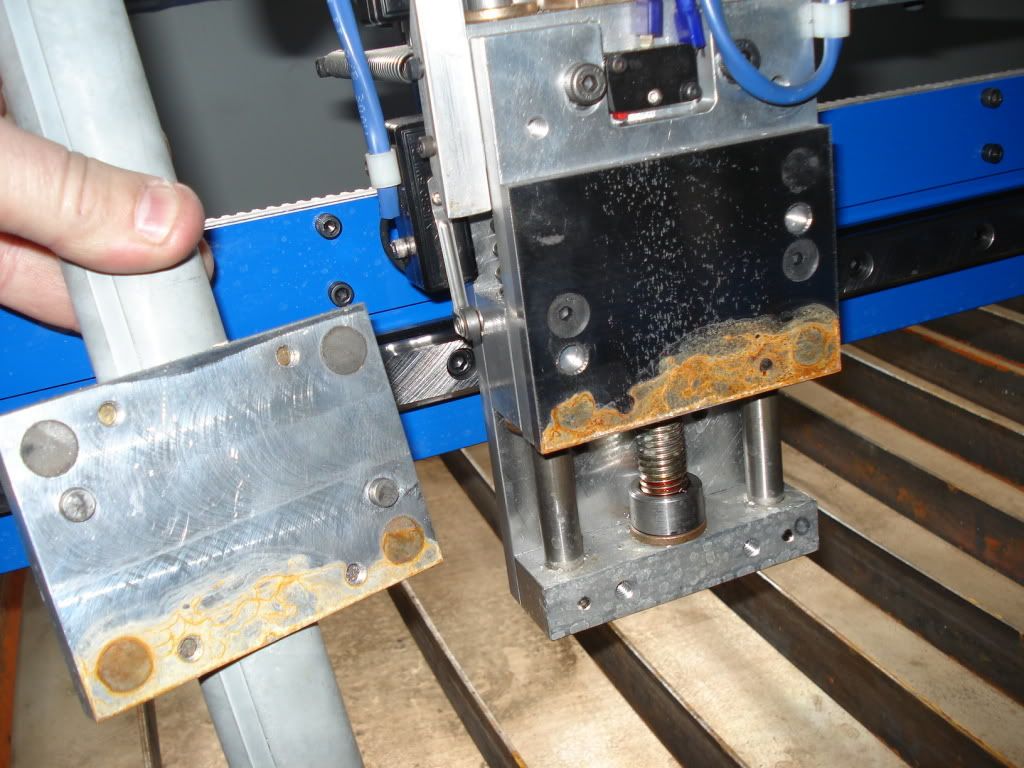

Here you go !!

Make sure you use rare earth magnets. Also, the pins only stick out just enough to locate the plate. If they stick out too far the torch may not break away in a side collision.

The magnets are pressed and loctited into the aluminum torch holder, and the plate that is mounted to my Z axis is made from mild steel (CRS).

I didn't bother putting a limit switch on it, because the unit will shut down if it doesn't see an arc. It wouldn't hurt to have one though.

I'm hoping to get my plasma quench sorted out soon so I don't get rust like in the second picture.

At the moment , I'm trying a Sodium Carbonate based product but I'm not sure how well it will work.

Time will tell !!

Dan

The one that dies with the most tools, WINS !!

The one that dies with the most tools, WINS !!

www.dantechfabricating.com

-

01-10-2012, 07:22 PM #24

Registered

Registered

- Join Date

- Dec 2011

- Posts

- 81

-

01-10-2012, 07:37 PM #25

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 303

I mentioned in my last post to use rare earth (neodymium) because they are super strong.

DanThe one that dies with the most tools, WINS !!

www.dantechfabricating.com

-

01-10-2012, 08:58 PM #26

Registered

Registered

- Join Date

- Dec 2011

- Posts

- 81

Yeah ... my brain didn't process the entire post all at once. Thanks.

How big are your magnets. I'm looking at these:

2 Neodymium Magnets 3/4 x 1/2 inch Disc N48 Rare Earth | eBay

They are 3/4 x 1/2 tall. I could buy a 1/2 dozen of them...

-

01-11-2012, 12:25 AM #27

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 303

Sure, they'll work !! I wouldn't use 6 of them though.

I used 1/2" dia magnets X 4.

These are 3/4 ", which means they will have about 2x the surface area, and double the pull.

How will you mount them if they are 1/2" thick?

Mine were 3/8 thick, so I used 1/2 thick aluminum to mount them in. I machined a pocket with a bottom.

If you use 1/2 thick magnets you will need 5/8 thick aluminum, which IMHO is getting thick, but will work.

DanThe one that dies with the most tools, WINS !!

www.dantechfabricating.com

-

01-13-2012, 01:45 AM #28

Registered

Registered

- Join Date

- Dec 2011

- Posts

- 81

I found the same magnets that you're using on ebay, Danno, and they should be here soon.

I wasn't aware of the difference between THC and a floating torch head. I thought both functions were basically operated from the same part of the control program... So I hope I can quickly figure out how to get both of them working. I bought the hypertherm connect cable with the Bladrunner 620 package to make things easier, too.

I just bought the Basic 2D Plasma Cutter Software Bundle today from candcnc and it will likely arrive about the same time as the main order from candcnc.com.

I'm waiting for one package of common flanged ball bearings to arrive and then I'll start putting some of the small parts together... I'm held up on the order for the ITVAAG and S V-Rail stock. The guy won't get back to me. The PCB Linear distributor doesn't answer emails or return phone calls... Not a great way to keep a customer happy... (wedge)

Without the v rails I can't really get the table drawing fully sorted out...

-

02-05-2012, 12:31 AM #29

Registered

Registered

- Join Date

- Dec 2011

- Posts

- 81

Hand held torch or machine torch?? What to buy?

Almost everything I've ordered has arrived. The Candcnc Bladrunner system arrived and looks awesome. It was well packaged and looks to be very well put together.

My pbclinear v-groove rail goodies are still not here and my Acklands-Grainger order for some small bushings seems to have been shipped to a big black hole... probably the same place as the pbclinear rails.

On a positive note, I'm about to purchase a Hypertherm 45 and wonder what I should buy. A machine torch setup or a hand torch version. I don't know how often I'd want to cut using a hand torch. Do the collars that hold the hand torch hold rigidly? I'm thinking I'll go with the hand torch version.

-

02-05-2012, 03:34 AM #30

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 303

That's a difficult decision. I was going to use the hand torch for my machine, but bought a machine torch also. If you're using it on a table, then get the machine torch version, and later on you can always buy a hand torch for it. I wouldn't use the hand torch on a machine for several reasons. The main one is that I didn't want to mess with the wiring of my plasma machine. Second, the Bladerunner system plugs right into the back of the machine. Using the machine torch makes for a cleaner more professional looking setup.

If I need to use my plasma for hand cutting, I don't have to take my machine appart.

DanThe one that dies with the most tools, WINS !!

www.dantechfabricating.com

-

02-05-2012, 02:41 PM #31

Member

Member

- Join Date

- Feb 2006

- Posts

- 1260

If it works.....Don't fix it!

Similar Threads

-

New Build Questions

By Imacman in forum Open Source CNC Machine DesignsReplies: 49Last Post: 02-04-2012, 02:49 AM -

Pre-build how-to questions

By Mountaincraft in forum MetalWork DiscussionReplies: 1Last Post: 01-27-2011, 04:57 AM -

New Build questions

By joebass in forum Plasma, EDM / Other similar machine Project LogReplies: 4Last Post: 01-01-2011, 12:14 AM -

New Build Questions

By PCFlyer in forum CNC Wood Router Project LogReplies: 4Last Post: 11-16-2010, 09:14 PM -

Questions about a new build

By bandtank in forum Joes CNC Model 2006Replies: 20Last Post: 10-24-2009, 03:31 AM

Reply With Quote

Reply With Quote