Check out this one Hoss;

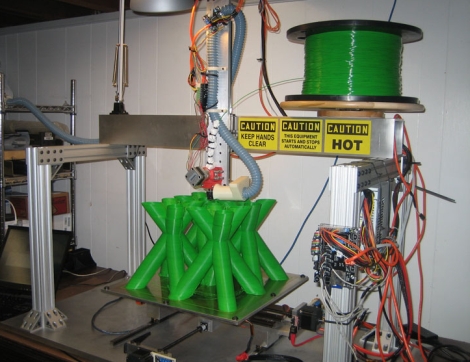

Huge DIY 3D printer predictably prints huge 3D items - Hack a Day

It's a nice big one.

I respect the whole makerbot philosophy that themachine can make more machines, but the implementation is gimicky with machines made from threaded rod and nuts and little plastic bits. It's sacrificing all performance all the time, for one benefit, the machine can make itself. Personally I think the machine should be designed to do it's job the best possible, so I'd build something like a fast precise gantry mill like the one above or the one RPovey linked in post #35.

I like plastics and have been keeping an eye on DIY 3D printers for a while. From what I've seen good results are very temperature dependent. So good control of table surface temp, extruder temp and even environment temp. A closed box around the machine might be a good option to have.

Yep that's exactly how it works.Originally Posted by Ger21

I've been watching that project too, until it fizzled. I think he may be going commercial with it, or doing research for commercial. It only gives a small work area maybe 2" square, and I'm not sure how long the LCD will survive. But for jewelery it's a very nice machine. And one of the easiest to build, if you have a projector LCD and one vertical axis.

Thread: Hoss's 3D Printers

Results 1 to 20 of 1431

Threaded View

-

02-08-2012, 09:36 AM #11

Registered

Registered

- Join Date

- Oct 2005

- Posts

- 2392

Similar Threads

-

mhackney's 3D Printers

By mhackney in forum 3D Printer / 3D Scanner DiscussionReplies: 164Last Post: 04-04-2014, 09:17 AM -

ROBO 3D Printers

By CNC_Kid in forum 3D Printer / 3D Scanner DiscussionReplies: 0Last Post: 01-13-2014, 09:13 PM -

Why have 3D printers in the classroom?

By cncadmin in forum 3D Printer / 3D Scanner DiscussionReplies: 0Last Post: 10-23-2013, 04:10 AM -

3D Printers why so quite on here?

By xairflyer in forum 3D Printer / 3D Scanner DiscussionReplies: 11Last Post: 07-17-2012, 04:55 AM

Reply With Quote

Reply With Quote