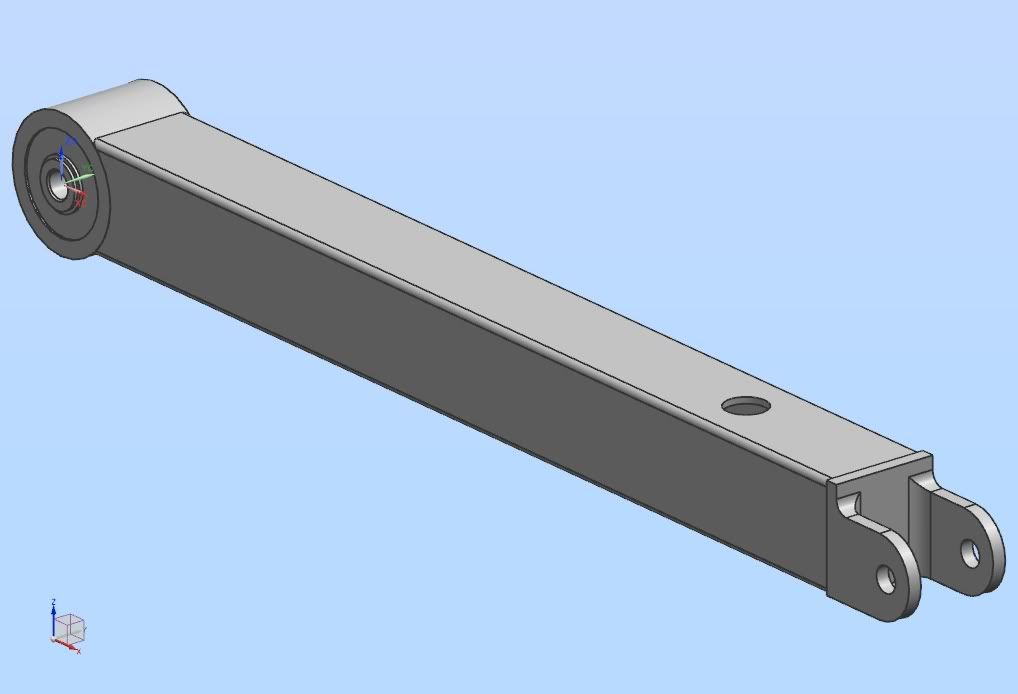

RFQ for CDW27 Lateral Control Arm Assembly:

QTY: 6, further orders expected.

TDP: Attached below

This is an open request for quotation.

Inspection Point is Destination

FOB is Destination

Bearings must be press fit.

All quotations must include shipping to 48043 Residential.

Due date for all quotes by 2/15/12

Submit all quotes to [email protected].

Thread: RFQ: Lateral Control Arm

Results 1 to 16 of 16

-

02-07-2012, 07:41 PM #1

Registered

Registered

- Join Date

- Mar 2007

- Posts

- 17

RFQ: Lateral Control Arm

-

02-08-2012, 05:02 AM #2

Registered

Registered

- Join Date

- Apr 2005

- Posts

- 713

And I thought the US government was a pain in the ass to deal with... Will you be telling the winning bidder how to hold his dick while he pisses, too?

-

02-08-2012, 05:12 AM #3

Registered

Registered

- Join Date

- Mar 2007

- Posts

- 17

Yes, no more than two shakes, any more is just playing with yourself, and I'll be damned you get your jollies off on my dime!

-

02-08-2012, 06:41 PM #4

Registered

Registered

- Join Date

- Mar 2007

- Posts

- 17

New TDP is uploaded including IGES files for those without the capability to view NX7 files.

Matt, what exactly am I being a pain in the ass about?

-

02-08-2012, 07:48 PM #5

Gold Member

Gold Member

- Join Date

- Apr 2007

- Posts

- 2580

Interesting....

I have made a bunch of stainless parts over the years. Does the length from the centerline to the pivot point really need to be .005"? I am sure I could fabricate those parts and I am a pretty damn good Tig welder but ensuring it does not move during the welding to keep it inside .005 would be tough... IS this a prototype job and what is the application. It LOOKS like a suspension part but not all stainless...? I am trying to decide if I want to bid this based on the specs. Thanks for putting it out here for us to look at things are slow here lately. Oh and don't mind Matt, I think he was just busting your balls... At least I hope so!! Hard to get work like that... haha peace

Pete

-

02-08-2012, 08:12 PM #6

Registered

Registered

- Join Date

- Mar 2007

- Posts

- 17

Yep, it's the center rear control arm for the Ford CDW27 platform. No, center line is not critical, the only thing that's critical is the length between centers as the platform has very little adjustment as is.

And yeah, I kinda figure that he was, thus the two shakes thing. txcncman was also kind enough to inform me that a few things in my solicitation can be a bit... out there, such as my use of google to host the TDP and my packaging spec, as well as my listed age being a little off putting to certain bidders. I'll be changing what I can shortly.

-

02-08-2012, 08:25 PM #7

Registered

Registered

- Join Date

- Apr 2005

- Posts

- 713

Busting balls is my specialty. Although your RFQ is reminiscent of dealing with the government regarding your shipping packaging callouts. That, and the RFID tags are exactly why I don't bid government work anymore. If you have the gall to charge for the time it takes to package and tag like they want, you're nowhere near a winning bid.

So why all the heat sealed stuff for a stainless part? I'm just curious. This quantity is too low for me.

-

02-08-2012, 08:30 PM #8

Registered

Registered

- Join Date

- Mar 2007

- Posts

- 17

Matt, I spend 4 hours a day translating MIL-STD-2073 specs for the rest of my estimating team, I wrote that packaging spec as fast as I could off of memory, not any need or requirement.

And I totally agree, I essentially mark P&S down about 70% and I still only have a 10% success rate with DLA jobs.

-

02-08-2012, 09:08 PM #9

Gold Member

Gold Member

- Join Date

- Apr 2007

- Posts

- 2580

Okay....

So this is say a lower control arm for a Ford Contour SVT or something then? I cannot imagine why anyone would want to pay for a Stainless Steel LCA for a car like that. I realize it will last FOREVER that way but a steel one with powdercoat would probably last as well. Honestly I shy away from anything that is involved in supporting or stopping a vehicle so I guess I am out here. Besides those tolerances on even a jig welded piece are gonna be tough I think. At least tough for me anyways. Good luck finding someone to make them for you and again thanks for posting the job. If you get something else you need done maybe I can help you. Peace

Pete

-

02-08-2012, 10:38 PM #10

Registered

Registered

- Join Date

- Mar 2007

- Posts

- 17

This is not for the average Contour, most of my customers participate in AutoX and are pushing 300HP, one excedes 500HP. The stock suspension on even the SVT Contour only differed in the springs and struts, the stamped control arms are one of the few components that have always been reviled but no one has ever made a serious attempt at replacing them.

-

02-08-2012, 11:32 PM #11

Gold Member

Gold Member

- Join Date

- Apr 2007

- Posts

- 2580

Sounds badass....

I always thought the SVT was a handsome car for what it is. I had a friend who had one and he liked it pretty good. Never thought of it as an AutoX car but I am a Fiero GT junkie so what the hell do I know anyways.... haha Good luck with your product man. Peace

Pete

-

02-08-2012, 11:57 PM #12

Registered

Registered

- Join Date

- Dec 2008

- Posts

- 319

What will the inspection method be for a completed part?

Will copies of the specs be provided with the PO?

-

02-09-2012, 02:49 AM #13

Registered

Registered

- Join Date

- Feb 2012

- Posts

- 0

Matt, I spend 4 hours a day translating MIL-STD-2073 specs for the rest of my estimating team, I wrote that packaging spec as fast as I could off of memory, not any need or requirement.

And I totally agree, I essentially mark P&S down about 70% and I still only have a 10% success rate with DLA jobs.

-

02-09-2012, 03:41 AM #14

-

02-09-2012, 06:31 AM #15

Registered

Registered

- Join Date

- Apr 2004

- Posts

- 40

the part i disagree with is the "not any need or requirement"... why put it in?

all it does is inflate the cost for something that is not important. this is my peeve with 'engineers' who forget to alter the tolerances on a print... we quote it and they wonder why it is so high.. then we mention the 0.002 tolerances all aver the place and they say 'oops'... waste of our time.

we make adjustable control arms for rock-crawlers. we make 'tunable' control arms for dragsters and other types race-cars...

i am not interested in this project, though.

good luck

-

02-17-2012, 01:40 PM #16

Registered

Registered

- Join Date

- Mar 2007

- Posts

- 17

Thank you all for interest and input on this, your suggestions and reminders will be helpful when I need other items made in the future. This job has been awarded.

Similar Threads

-

Deflection of tool vs lateral forces

By PaulRowntree in forum DIY CNC Router Table MachinesReplies: 12Last Post: 06-04-2011, 03:02 AM -

closed loop vector control frequency inverters for energy saving & process control

By greendriv in forum News AnnouncementsReplies: 0Last Post: 02-10-2011, 03:05 PM -

Cards Support Stepper Motor Driver Control & AC Servo Control.

By Johnnyatcnc in forum News AnnouncementsReplies: 0Last Post: 04-09-2010, 09:57 AM -

15i control help for (AiCC) (hpcc) high precision contour control programming

By gibbsmaster in forum FanucReplies: 2Last Post: 12-28-2007, 04:57 PM -

Using Flashcut CNC Spindle rotate card control to control laser power

By pyroplotter in forum FlashCut CNCReplies: 0Last Post: 10-16-2007, 03:46 AM