I would say yes, because I think it's far easier to add material to the gantry risers to stiffen them up, than to try and add plates and stiffeners to an already cramped place like a carariage, especially if adding weight would be a hindrance to your stepper choice.

But in terms of your machine - if you fixed the rails, with the 7" of clearance you have under the gantry, you would have to make your carriage in such a way that the collet is 7" away from the lower bearing to reach the table surface. Then if you wanted to retract it all the way up, you would have the lower bearing 14" from the table surface, not including the bearing spread! With moving rails, you'd have almost full support all the way up, and a max of 7" fully down.

Results 41 to 58 of 58

-

02-26-2012, 02:01 AM #41

Gold Member

Gold Member

- Join Date

- Apr 2009

- Posts

- 5516

-

02-26-2012, 10:44 AM #42

Registered

Registered

- Join Date

- Jun 2006

- Posts

- 47

Hi Tricky,

I also built the “Z” that way, I will try to make the “Y” side supports higher so I can utilize the nice “Z” travel and clearance that I have.

A few more pictures, if your interested.

http://www.cnczone.com/forums/diy-cn...y_machine.html

Cliffy.

-

02-26-2012, 01:56 PM #43

Gold Member

Gold Member

- Join Date

- Apr 2009

- Posts

- 5516

-

02-26-2012, 07:18 PM #44

Registered

Registered

- Join Date

- Aug 2011

- Posts

- 617

Yes Cliffy, very nice

so .. I found some steel tube I can use for rails ... It's part of an old bunk bed I didn't throw away (as it could be useful !)

Ive designed the Z in my head, but didn't start making it yet, as I'm feeling a bit off. I'm getting pretty sure I'm getting sensitized to MDF dust, and it's making me quite ill . Really bad cold and Flu type symptoms...

For most work I use my double filter face mask, but the odd cut without the mask is catching me out, and knocking me for 6 !

anyone else getting killed by MDF dust ?

RichMy 1st Build (ongoing) http://www.cnczone.com/forums/diy-cnc_router_table_machines/134670-one_big_one_smaller_my.html

-

02-26-2012, 07:53 PM #45

Gold Member

Gold Member

- Join Date

- Apr 2009

- Posts

- 5516

I think some MDF has urea formaldehyde glue... not a good thing to breathe! Any fine particulate is probably not good anyway...

-

02-27-2012, 11:21 AM #46

Registered

Registered

- Join Date

- Aug 2011

- Posts

- 617

while thinking aboout the Z, I had the thought that you could make your own Hiwin type rails. Two round bars , supported, and two angle skate bearing truck, in a suitable holder / block

My 1st Build (ongoing) http://www.cnczone.com/forums/diy-cnc_router_table_machines/134670-one_big_one_smaller_my.html

-

02-27-2012, 08:04 PM #47

Gold Member

Gold Member

- Join Date

- Apr 2009

- Posts

- 5516

-

02-27-2012, 09:00 PM #48

Registered

Registered

- Join Date

- Mar 2007

- Posts

- 28

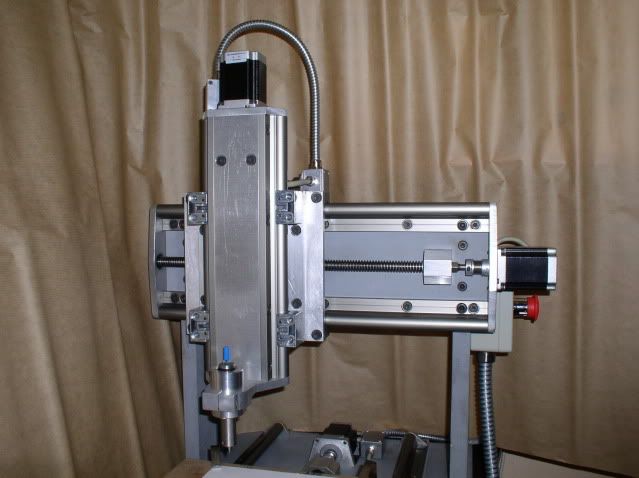

It really depends on what type of linear system you are using, if you look at the pictures here you see I use v-groove bearings for my linear motion. I have found this to give me good stability through my most common cut range, (total z movement is 6" and I am usually cutting at about -3

-

02-27-2012, 10:00 PM #49

Gold Member

Gold Member

- Join Date

- Apr 2009

- Posts

- 5516

-

02-27-2012, 10:50 PM #50

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 16

-

02-27-2012, 10:56 PM #51

Gold Member

Gold Member

- Join Date

- Apr 2009

- Posts

- 5516

-

02-28-2012, 12:08 AM #52

Registered

Registered

- Join Date

- Aug 2011

- Posts

- 617

-

02-28-2012, 12:39 AM #53

Gold Member

Gold Member

- Join Date

- Apr 2009

- Posts

- 5516

Joe's2006 is moving bearing... just for an example of moving bearing. The underlying similarity is the use of skate bearings at a 90 degree angle, and a way to 'press' those bearings against the rail. In the case of Joe's, it's u-bolts and bearings. On the Solsylva, the bearing trucks are on the carriage sides, and preload is affected by drawing the sides together or shimming the trucks with brass shim stock...

-

02-28-2012, 01:15 AM #54

Registered

Registered

- Join Date

- Mar 2007

- Posts

- 28

Yeah, I assembled it in the "theater room" but shhhh don't tell the wife, she thinks it's her new vacum. I knew i was going to catch crap for taking those pictures, but as you can see my point is valid, either way can work, it all depends on the engineering.

-

02-28-2012, 03:30 AM #55

Registered

Registered

- Join Date

- Aug 2011

- Posts

- 617

ah, I was looking at joes hybrid. with the V-groove bearings. very simple and easy to build design ! I don't know if I trust v-grooves for side thrust though ? And they're quite pricey .

My 1st Build (ongoing) http://www.cnczone.com/forums/diy-cnc_router_table_machines/134670-one_big_one_smaller_my.html

-

02-28-2012, 05:43 AM #56

Registered

Registered

- Join Date

- Oct 2008

- Posts

- 1147

This point may have been already made but the one big plus of having fixed rails and moving bearings is your Z clearance once your router bit is in. On my first build I didn't take that into consideration and then was shocked when I only had 2 inches of clearance with a 3 inch router bit in the router. That's why I'm for fixed rail and moving bearings even if it means my Z axis may need to stick out a little further. To get the same clearance with fixed bearings would mean I would have to make the gantry taller.

-

02-28-2012, 05:58 AM #57

Gold Member

Gold Member

- Join Date

- Apr 2009

- Posts

- 5516

That would probably be poor planning rather than design consideration! (nuts)

In Rich's particular case, the gantry clearance is already 7". So if you wanted to utilize that 7" of clearance, and have fixed rails, the spindle collet would end up being 7" from the lower bearing. So then fully retracted that same bearing would be 14" from the table surface! Which is easier then, trying to make that carriage and high saddle stiffer, or making the gantry legs stiffer?

I do think for shorter travels, the fixed rail would be a good option that would be easier to implement...

A few guys that had built Joe's Hybrid had added bearings behind the plate (on the z) to aid in thrust loads... they're used however on ShopBots and MechMate...

-

02-28-2012, 06:22 AM #58

Registered

Registered

- Join Date

- Oct 2008

- Posts

- 1147

Poor planning, yea... but good execution. It was my first build and I'm was damn proud of it. Truthfully, I designed the Z axis after I had built the X and Y. It came down to building a fixed rail with a wide z for more clearance or or a narrower Z with less clearance. Learned a lot from that little hardware store contraption.

I think it's easier to stiffen up the Z drop down plate then the gantry sides and possibly the Y axis depending on how high you're planning to go. I don't know what the OP is planning on cutting but my vote is still on fixed rails.

Similar Threads

-

Trade offs between Moving Gantry and Moving Table

By gregmary in forum DIY CNC Router Table MachinesReplies: 11Last Post: 04-22-2011, 07:48 PM -

Moving Table, or Moving Gantry? (For Router)

By Cryptonic26 in forum DIY CNC Router Table MachinesReplies: 6Last Post: 04-20-2011, 08:38 AM -

Z DRO moving, axis not moving

By JC50 in forum DIY CNC Router Table MachinesReplies: 9Last Post: 03-13-2011, 02:49 AM -

Discussion of moving table vs moving gantry

By rkremser in forum DIY CNC Router Table MachinesReplies: 5Last Post: 02-20-2008, 10:59 PM -

Moving Table vs Moving Gantry; Dremel vs Router

By chuckknigh in forum DIY CNC Router Table MachinesReplies: 32Last Post: 03-28-2007, 02:48 AM

Reply With Quote

Reply With Quote