I started on the plate for the 2 stage air cylinder and took some cuts. I put a tool in, fully inserted it using the gripper with the balls and then manually tightened the bolt on top of belville washers with a wrench. No problem taking .2" cut with a glacern 4" face mill at 6000 rpm- it is holding just fine.

Results 81 to 100 of 100

-

03-07-2013, 03:36 AM #81

Registered

Registered

- Join Date

- Mar 2010

- Posts

- 156

-

03-08-2013, 06:07 PM #82

Registered

Registered

- Join Date

- Jun 2011

- Posts

- 0

-

03-12-2013, 04:45 AM #83

Registered

Registered

- Join Date

- Mar 2010

- Posts

- 156

UPDATE:

My effort to convert my RF45 clone to bt30 with a power draw bar works. I am really happy because bt30 tooling is plentiful and cheap

Video below:

-

03-12-2013, 03:31 PM #84

Registered

Registered

- Join Date

- Jan 2012

- Posts

- 469

Fantastic, great to see it working! I had seen some other ball gripper attempts that in the end proved not to be so great, so well done!

-

03-12-2013, 10:50 PM #85

Registered

Registered

- Join Date

- Jun 2011

- Posts

- 0

Looking good. ...well done

Eoin

Eoin

-

04-01-2013, 08:40 PM #86

Registered

Registered

- Join Date

- Mar 2010

- Posts

- 156

Update:

I cleaned up everything with the enclosure and things are starting to come together. A few pics of the mill in it's current state with a power drawbar, one shot oiler, enclosure and diy fog buster with pressurized coolant:

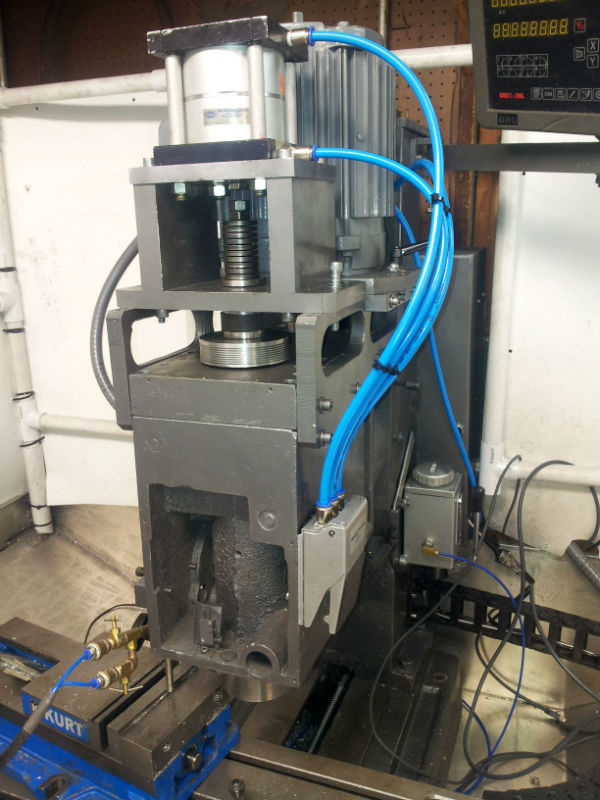

Shot of the mill head with the bt30 power drawbar installed:

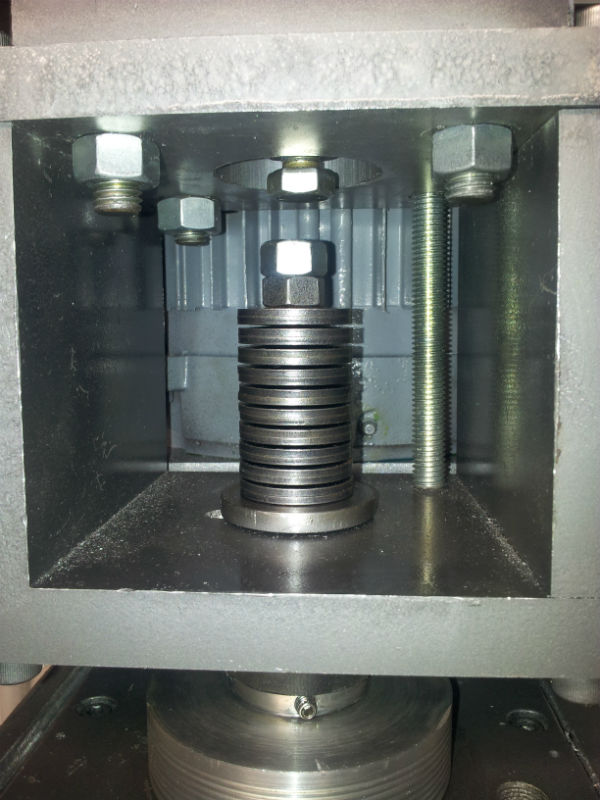

Belleville springs:

Overview shot showing the enclosure. You can also kind of see the 3.5" head extension. I am getting a full 12.75" of Y travel now. I will need to make a fixture plate to take full advantage. Considering these mills have 8" of y travel, this is really awesome:

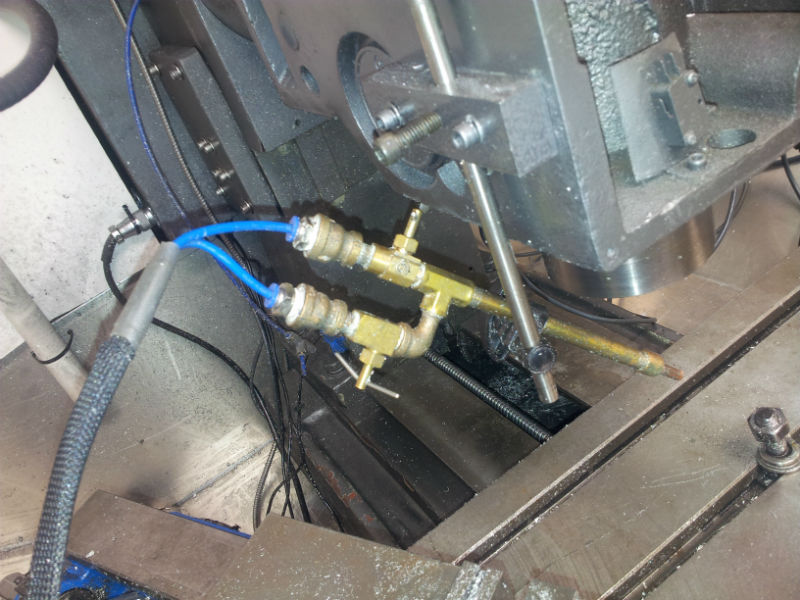

Power drawbar switch. I ended up using a foot pedal momentary pneumatic switch. Seems more robust than the toggle type and the price is right:

Diy fog buster built out of scrap 1/8" npt plumbing parts I had around and a mig nozzle tip. I forgot to snap a pic of the pressurized coolant tank but it is a whole house water filter housing modified with a pick up tube. compressed air goes in and forces the coolant out through the pick up tube connected to the top. The needle valves allow for both pressure and fluid level adjustments. Works really well:

Thanks for looking...

-

07-09-2013, 04:30 PM #87

Registered

Registered

- Join Date

- Mar 2010

- Posts

- 156

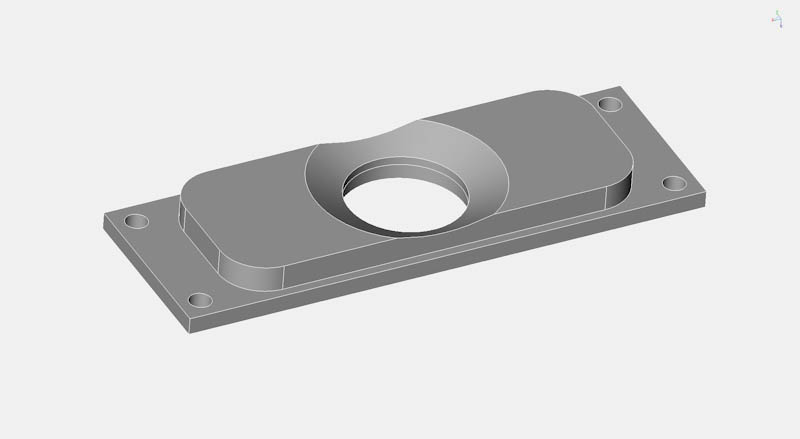

Now the the mill is functional, I have been busy learning to make stuff with it. Currently I am working on making 4 lights for the front bumper of my truck.

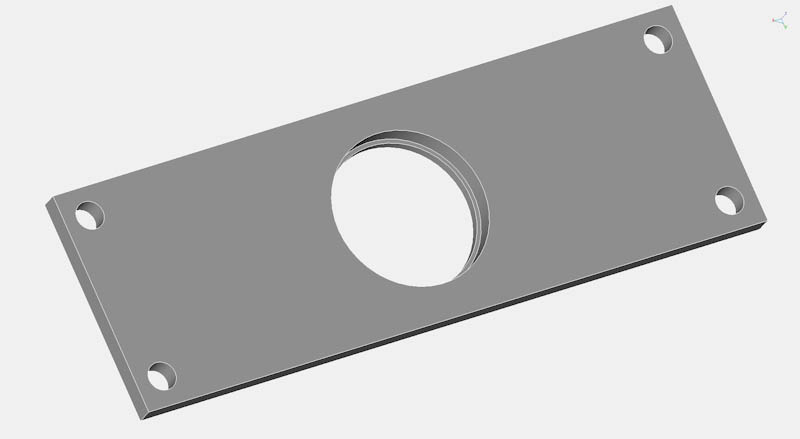

This is my first attempt to make a light entirely with cnc. It is designed to fit flush in the front Addictive Desert Design bumper on my ford Raptor truck. When I ordered the bumper, I had them make a custom plate so I could mount lights in the bumper itself. The lights will be cerakoted and each light is a triple xm-l board running task led driver. The body of the light is designed to fit tight in the bumper and transfer heat to the bumper as well as act as a heat sink.

Rendering:

Top:

Bottom:

Machined top:

Bottom:

Test fitting in the bumper:

There will be 4 of these to fit in the cutouts on the bumper. Should be 10k + lumens with the flick of a switch.

Video of the part being machined:

I will post more after I make the back. The whole light will then be cerakoted and mounted.

FYI, It took 1 hour to measure and draw the part in cad and 15 minutes to machine the top + 5 minutes to setup and cut and profile the bottom hole. I am really happy to be able to draw something out and actually see it take form. The best part was drawing it out in cad and then seeing the finished part fit perfect.

Thanks for looking

-

11-04-2013, 08:36 AM #88

Registered

Registered

- Join Date

- Oct 2009

- Posts

- 483

gt40,

Any updates to your build thread?

Great pics and video of your first project for your Ford Raptor.

Tell us more about the 12.75" of Y-travel. I see you have a head spacer, but I don't see a column spacer? Had you increased the Y-travel before you went with the head spacer? If yes, what was that pre-spacer Y-travel?

Also loved the home-built sheet metal brake.

Titaniumboy

-

01-14-2014, 12:46 AM #89

Registered

Registered

- Join Date

- Jan 2007

- Posts

- 277

-

11-13-2014, 05:28 AM #90

Registered

Registered

- Join Date

- Mar 2010

- Posts

- 156

Re: PM45m(rf45 clone) cnc build log with factory 3hp variable speed

Update:

After a year and a half, the ball gripper is failing. The issue is the hardened balls are deforming the inside of the spindle and it fails to eject or receive a tool at times. I got a chinese petal clamp and am going to try to retrofit it.

Will post more after I receive the clamp.

-

11-14-2014, 03:36 AM #91

Registered

Registered

- Join Date

- Jun 2005

- Posts

- 1015

Re: PM45m(rf45 clone) cnc build log with factory 3hp variable speed

have you thought about using a hardened sleeve to protect the spindle?

-

11-14-2014, 10:24 PM #92

Registered

Registered

- Join Date

- Aug 2014

- Posts

- 161

Re: PM45m(rf45 clone) cnc build log with factory 3hp variable speed

Great thread. Is it just me or does it look like that bumper was tack welded together? Your custom lights are pretty slick.

-

11-20-2014, 02:41 PM #93

Registered

Registered

- Join Date

- Mar 2010

- Posts

- 156

Re: PM45m(rf45 clone) cnc build log with factory 3hp variable speed

It is pretty cramped in there with the stock 30 taper spindle but I am going to take measurements when I get the petal style gripper. The main issue is the ball bearings are hard on not only the spindle but the pull studs and they are deforming slowly too.

Thanks for the light comments. As far as the bumper, it is an Addictive Desert Designs venom and is pretty well built actually.

-

11-20-2014, 08:53 PM #94

Registered

Registered

- Join Date

- Jun 2005

- Posts

- 1015

Re: PM45m(rf45 clone) cnc build log with factory 3hp variable speed

is there a reason you didn't use commercially available pull studs? also would you be willing to share your prints of the mods since your going to the petal clamp?

-

11-21-2014, 02:49 PM #95

Registered

Registered

- Join Date

- Mar 2010

- Posts

- 156

Re: PM45m(rf45 clone) cnc build log with factory 3hp variable speed

I used Emco F1 P50 pull studs because I found a batch cheap on ebay and they looked like they would fit:

Attachment 257788

-

05-29-2015, 02:33 AM #96

Registered

Registered

- Join Date

- May 2008

- Posts

- 83

Re: PM45m(rf45 clone) cnc build log with factory 3hp variable speed

How many and what are the p/n numbers for the Belleville washers. I am trying to accomplish the same type of pull stud gripper and am having difficulty trying to figure out the right amount and right lbs for bellvilles.

-

05-29-2015, 02:53 AM #97

Registered

Registered

- Join Date

- Mar 2010

- Posts

- 156

Re: PM45m(rf45 clone) cnc build log with factory 3hp variable speed

I forget the exact number but theres pics on this thread somewhere you should be able to count. Here is the one I ordered:

McMaster-Carr

Hope this helps.

-

05-29-2015, 07:06 PM #98

Registered

Registered

- Join Date

- May 2008

- Posts

- 83

Re: PM45m(rf45 clone) cnc build log with factory 3hp variable speed

when installing these washers how did you go about tightening them or torqueing them to get the correct preload? Did you torque them to a specific torque spec and if so how do I determine what that is?

-

05-31-2015, 02:36 PM #99

Registered

Registered

- Join Date

- Mar 2010

- Posts

- 156

-

06-01-2015, 12:43 AM #100

Registered

Registered

- Join Date

- May 2008

- Posts

- 83

Re: PM45m(rf45 clone) cnc build log with factory 3hp variable speed

Thank you for your help, the info is greatly appreciated. Now hopefully I can make some progress with this auto tool changer.

Similar Threads

-

An Aussie IH Clone Build (Long Travel RF45)

By Wallerawang in forum Benchtop MachinesReplies: 91Last Post: 08-28-2014, 10:22 AM -

What RF45 clone should I get?

By Nigel Tufnel in forum Benchtop MachinesReplies: 2Last Post: 12-03-2013, 06:24 AM -

Build Thread: HF 8x12 variable speed DC motor conversion

By gt40 in forum Mini LatheReplies: 1Last Post: 04-13-2010, 10:16 PM -

X3 or RF45 clone?

By logjammer in forum Benchtop MachinesReplies: 13Last Post: 12-14-2006, 03:34 PM -

convert rf45 type to belt variable speed and some cnc info?

By ataxy in forum Knee Vertical MillsReplies: 20Last Post: 09-03-2006, 04:58 PM

Reply With Quote

Reply With Quote