Hi all, i'm a long time reader, first time poster. I have experience in CNC and own an A3 sized desktop one and want to upgrade with a new home build. Basically i just want to cut mdf and ply with it, speed and really tight accuracy are not really that important and I have yet to calculate my motor requirements except that I'm going nema 23 for size.

I just wanted maybe a more experienced builder or anyone in the know really to have a look at my design and see if there is anything obvious that might hold my design back before I commit to ordering the parts.

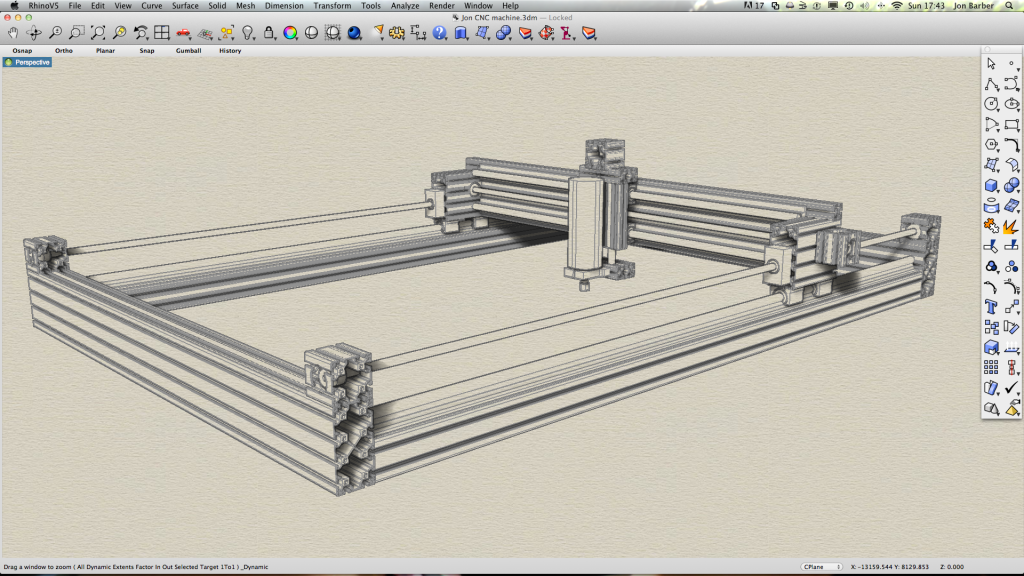

The goal was to create it as cheap as possible but try and keep rigidity. I've used 16mm multi-start trapezoidal lead screws on x, y and z. Fully supported 16mm rails on x and y and 16mm round rail on z. My main concern is the lead screws on x sagging?? The machine is 1500mm x 1000mm at the rails.

Any advise would be greatly appreciated. Thanks

Thread: CNC design for consideration?

Results 1 to 5 of 5

-

03-18-2012, 07:01 PM #1

Registered

Registered

- Join Date

- Mar 2012

- Posts

- 0

CNC design for consideration?

-

03-21-2012, 02:04 AM #2

Registered

Registered

- Join Date

- May 2010

- Posts

- 0

Why not use steel square tubing? That material is a lot cheaper.

-

03-21-2012, 02:08 AM #3

Community Moderator

Community Moderator

- Join Date

- Mar 2003

- Posts

- 35538

Personally, I'd try to move the screws down and out of the way, unless you want oil and or grease on your arms all the time from reaching over them.

Gerry

Gerry

UCCNC 2017 Screenset

http://www.thecncwoodworker.com/2017.html

Mach3 2010 Screenset

http://www.thecncwoodworker.com/2010.html

JointCAM - CNC Dovetails & Box Joints

http://www.g-forcecnc.com/jointcam.html

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

03-21-2012, 02:20 AM #4

Registered

Registered

- Join Date

- Feb 2012

- Posts

- 0

I'd use 30mm or better for the bottom X-axis rails,keep with the 16mm as guide rails.

-

03-21-2012, 02:25 AM #5

Registered

Registered

- Join Date

- May 2010

- Posts

- 0

I would make the machine with a consideration that all moving parts can be covered in nylon fabric sleeves.

That will keep the abrasive dust off the bearings and make the machine run better/longer.

So I would hide the screw underneath metal guides so it won't touch the fabric sleeve.

Similar Threads

-

fixture consideration

By XXF in forum MastercamReplies: 2Last Post: 06-21-2011, 04:05 PM -

Electronic components consideration in mechanical design

By coykiesaol in forum Mechanical Calculations/Engineering DesignReplies: 1Last Post: 10-26-2010, 04:27 PM -

Finding Engineering Design Software For Automatic Machine Design

By hellokitty in forum Uncategorised CAM DiscussionReplies: 0Last Post: 01-06-2008, 07:39 AM -

Mach2 consideration questions

By jevs in forum Mach Software (ArtSoft software)Replies: 16Last Post: 02-19-2005, 01:47 AM -

Designs for open source consideration

By pminmo in forum CNC Machine Related ElectronicsReplies: 4Last Post: 07-18-2004, 03:54 PM

Reply With Quote

Reply With Quote