Sure hope I can get some good advice on choice of spindle for my home assembled CNC router.

It's time to think about the Z axis and choose a method to drive the end mills.

My machine will be mostly used to make model helicopter sideframes. Protoypes will be out of 2mm plywood (I was getting pretty good with transfer punches and my scroll saw, but I now need greater accuracy to finish off the various designs). Final frames will be made out of 1.6mm fibreglass and aluminium sheet. There will also be some brackets out of 6mm aluminium plate and perhaps an exhaust gasket made out of 2mm stainless steel.

I have been thinking about a 0.75kW 24,000rpm VFD spindle like this:

High Speed Spindles, Motors & Inverters - Arc Euro Trade

But have a Sherline ER16 10,000rpm spindle:

spindles

With the Sherline spindle, I'd use a T5 belt and pulley drive arrangement with a 240V AC motor out of a 2kW electric blower with its crude variable speed controller. The gear reduction would need to be 1.5:1 since the AC motor could do around 15,000rpm.

The VFD spindle is a nice solution, but not sure how capable it would be at slower speeds assuming my duty with aluminium and stainless steel would require it.

The Sherline option would be heavy and limited to 10,000rpm but may be the better choice.

I'd like some good advice on which way to go.

Thanks.

Results 1 to 8 of 8

-

04-22-2012, 01:25 PM #1

Registered

Registered

- Join Date

- Mar 2011

- Posts

- 14

Spindle Choice for Routing Machine - VFD or Sherline?

-

04-22-2012, 06:03 PM #2

Registered

Registered

- Join Date

- Nov 2006

- Posts

- 1036

I had a 10k Sherline spindle for a while and found it got very hot with prolonged use at 10k (even when I loosened the bearing preload). I suggest you test for that before you make your decision. BTW my Taig spindle works fine at high speed but that is probably irrevelant to you.

Just reread your post. You will probably want to keep your Sherline for milling aluminum at lower rpms than possible with the VFD spindle. Stainless steel is very hard to mill and most routers are not rigid enough for that.

-

04-22-2012, 06:33 PM #3

Registered

Registered

- Join Date

- Sep 2010

- Posts

- 0

Teknomotor

Hi brw0513,

try this Teknomotor ER20-0.7KW-24000RPM, on my experience i don't encounter

problem with this spindle.

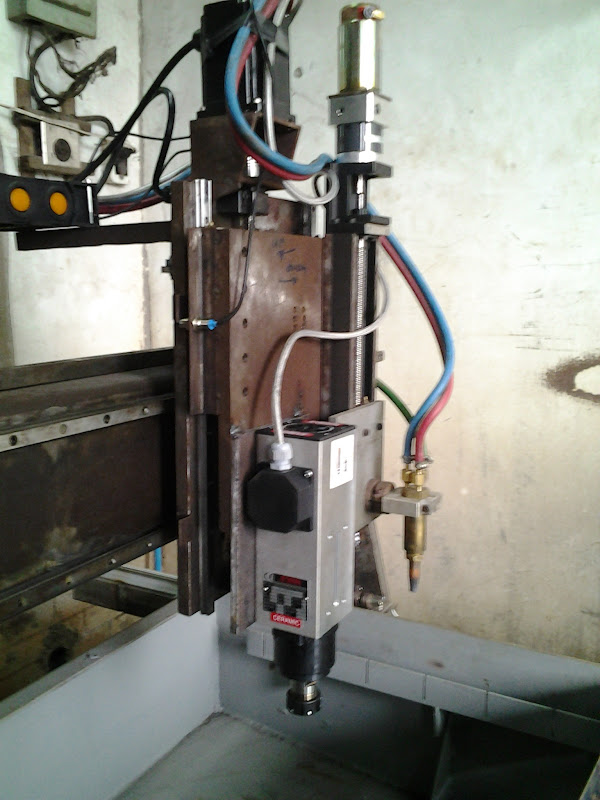

here is my cnc machine right now i am using ER25-2.0KW-24000RPM

Also this is my VFD

-

04-23-2012, 11:34 AM #4

Registered

Registered

- Join Date

- Mar 2011

- Posts

- 14

-

04-23-2012, 11:50 PM #5

Gold Member

Gold Member

- Join Date

- Apr 2009

- Posts

- 5516

You might need both....

-

04-25-2012, 09:35 AM #6

Registered

Registered

- Join Date

- Sep 2007

- Posts

- 200

i recommend the sherline spindle. i use a taig ER spindle coupled to a 500watt 5000rpm sangmutan brushless DC motor. it has the speed range to do things with the smaller bits and has the grunt to power the 10mm endmills i use mostly. the motor and speed controller i have is great it is accurately variable from 400 to 5000, can forward and reverse at a moments notice, and the display is easy to read. the trick is finding a good supplier. sangmutan is a chinese supplier and got beat up because it had a small market. keep a look out for something similar. the hi-torque mill on littlemachineshop is a similar motor.

-

04-25-2012, 09:44 AM #7

Registered

Registered

- Join Date

- Sep 2007

- Posts

- 200

i just googled, and sangmutan is still around. what i did when i ordered was email for a special order of a controller with a smaller frame motor. the motor i asked for was 500watt in a 80mm square frame. it just turned out that they had access to a motor like that with a top speed of 5000rpm.

the sherlines top speed is not the sort of thing you want to go over anyway.

-

04-25-2012, 12:34 PM #8

Registered

Registered

- Join Date

- Mar 2011

- Posts

- 14

Thanks for the replies.

To get a feel for the Sherline spindle at speeds up to 10,00rpm I made up a belt drive "jig" today. The gear ratio was a bit taller than ideal - just selected on the T5 pulleys I had available. I didn't adjust the bearing preload, but the spindle sure got rather hot after just a few minutes. And the combination of motor and spindle was rather heavy.

I've decided to further pursue the VFD arrangement.

The TeknoMotor spindle mentioned by rexcobey does seem a good candidate if I keep the end mills small enough (i.e. max of 1/4" dia, 1/8" even better) and forget the idea of machining stainless steel on my router.

The advice I've received from DamenCNC.com about the C31/40-C-SB-P-ER20-0.7KW-18000RPM TeknoMotor HF spindle has been terrific. If they can satisfy me about warranty and a few other questions, then they deserve my business.

Similar Threads

-

Sherline spindle a good choice?

By pwg1824 in forum Benchtop MachinesReplies: 2Last Post: 05-09-2012, 10:45 PM -

Tool Bit & Spindle Choice for Router

By brw0513 in forum DIY CNC Router Table MachinesReplies: 2Last Post: 09-12-2011, 09:45 AM -

Spindle Choice

By bassman2914 in forum Commercial CNC Wood RoutersReplies: 1Last Post: 09-16-2010, 05:58 PM -

Sherline or Taig spindle on their machine?

By cnctoolman in forum DIY CNC Router Table MachinesReplies: 5Last Post: 06-08-2010, 02:25 PM -

Spindle choice - Glass CNC

By digital in forum DNC Problems and SolutionsReplies: 3Last Post: 10-30-2004, 05:37 AM

Reply With Quote

Reply With Quote