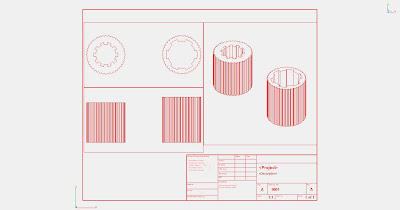

Have couple questions about splines; trying to reverse engineer a part. I know very little about machining but have a friend with CNC Machine shop; and I can use equipment for free. I am trying to build part like pic. Few Questions:

1)How do I know if part is involute or straight spline

2)If I knew what broach to get could I cut 6 and 10 spline internal by cutting one spline at a time then rotate to do next spline or would I need a broach that did all splines together. From my understanding a broach like this would be $$$$$$$$$

4)As far as the 40 spline sections I plan on using mark williams

http://1.bp.blogspot.com/_N5raeDVd7b...+coupling1.bmp

Thread: Help with Spline

Results 1 to 7 of 7

-

10-03-2010, 04:51 PM #1

Registered

Registered

- Join Date

- Jul 2007

- Posts

- 8

Help with Spline

-

10-04-2010, 01:44 AM #2

Member

Member

- Join Date

- Aug 2009

- Posts

- 684

Hi,

You need to attach your pics in a way they can be enlarged. The internal looks straightforward, can't tell if the external is involute or not, but if it engages with some other cogs/gears then it probably is - look at this: -

Involute gear - Wikipedia, the free encyclopedia

As you can see this is a complex form and you would need a bespoke piece of tooling to produce it. You also need to know the relevant dimensions of the mating parts to determine the shape of each involute arc.

If the parts are very large (ie big enough to poke a milling head attachment into - can't tell from drawing) then the internal spline could be milled. Not the best way if you require job to be done with high accuracy though...

If components are small you need some kind of slotting machine - or better, a proper gear-cutting hobber - and the cutter profile you use will depend on that machine's capabilities as well as the other constraints of money/time and finish/accuracy required.

Of course you could clamp a basic tool directly to a spindle head/turret and use a CNC mill/lathe as a slotter if your friend doesn't mind...

DP

-

10-04-2010, 02:58 AM #3

Registered

Registered

- Join Date

- Jul 2007

- Posts

- 8

sorry about size of pics but internal spline approx 1 3/16 outside spline is 1.7083 major diameter and would be cut using 45 degree from mark williams. The 45 degree pressure splines are not really the problem b/c MW does these pretty cheap like $150. My concern is cutting the inside splines I have seen broaches go for as little as 50-60 bucks. I would rather do the 10 spline and six spline part myself just wondering if I can get the proper measurements and broach can I do this with indexing head and CNC Mill or even a press. I'm more intrested in the process. I may end up making some of these for sale and if I had the broachs for 6 and 10 spline I could send the other out to Mark Williams. If this can be acomplished with single spline broach and I could get broachs for few hundred bucks I would rather do it that way. I just have no idea about the process and tooling cost. I know multispline broaches are hella expensive. As far as that goes if broaches are as cheap as I have seen some on ebay I would buy one for the 40 spline part and spend several nights at shop turning an indexer. Also if that were the case how much would a cutter be to do the outer 40 spline. The way I figure if I could spend 500-600 on tooling I would do it all myself.

-

10-04-2010, 04:09 AM #4

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 2712

Try Grob, Inc. - Industrial Band Saws And Cold Rolled Metal Products might be helpful. Click on cold rolled products.

Dick ZDZASTR

-

10-04-2010, 06:19 AM #5

Registered

Registered

- Join Date

- Jul 2007

- Posts

- 8

That looks like exactly what I wanted I sent email requesting quote hopefully since they have what I want on the shelf won't be too expensive.

Anyone offer help on broach for 6 spline and 10 spline part in above pic I would give some measurements but don't know what to measure other than diameter.

-

10-04-2010, 09:38 PM #6

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 2712

6 spline appears to be straight spline.

1.) How wide are the spline slots?

2.) What's the width across the bottom of spline slots?

3.) what's the inside diameter of the bore?

Dick ZDZASTR

-

06-01-2012, 07:26 PM #7

Registered

Registered

- Join Date

- Sep 2003

- Posts

- 6

Old thread I know, but for the record it is quite easy to do *some* internal straight splines with a keyway broach. For instance, I had to make a Colchester Chipmaster gear which has a 7/8" SAE six straight spline hub (equates to almost exactly 20mm minor diameter). I bored to 20mm then used a 6mm keyway broach and with a modified broaching bush. The bush had an extra slot offset from the main slot by 60 degrees. The extra slot holds a thin 6mm feather key. Internal splines are made by cutting shallow keyways one at a time, each offset by 60 degrees to the former. For each keyway, the feather key engages in the previously broached slot. I had to make a different shim for the broach from a bit of brass sheet. I also made one of the keyways a full depth 6mm keyway, so the gears could be used on 7/8" SAE splined shaft or a 20mm diameter 6mm keyed shaft.

Richard

Similar Threads

-

Take a look spline job

By turboless in forum Employment OpportunityReplies: 0Last Post: 05-22-2009, 04:04 AM -

mastercam and spline

By zewanil in forum MastercamReplies: 4Last Post: 05-02-2009, 06:16 AM -

RFQ spline broaching

By timmydabull in forum Employment OpportunityReplies: 13Last Post: 10-06-2008, 12:51 AM -

spline help,mc9.1

By GRANDPA in forum MastercamReplies: 10Last Post: 03-10-2007, 01:00 PM -

Spline

By scottsss in forum AutodeskReplies: 13Last Post: 07-15-2003, 04:30 AM

Reply With Quote

Reply With Quote