Having the problem that, even with candcnc set at 5% my Z tends to move too fast....and do the sewing machine style.

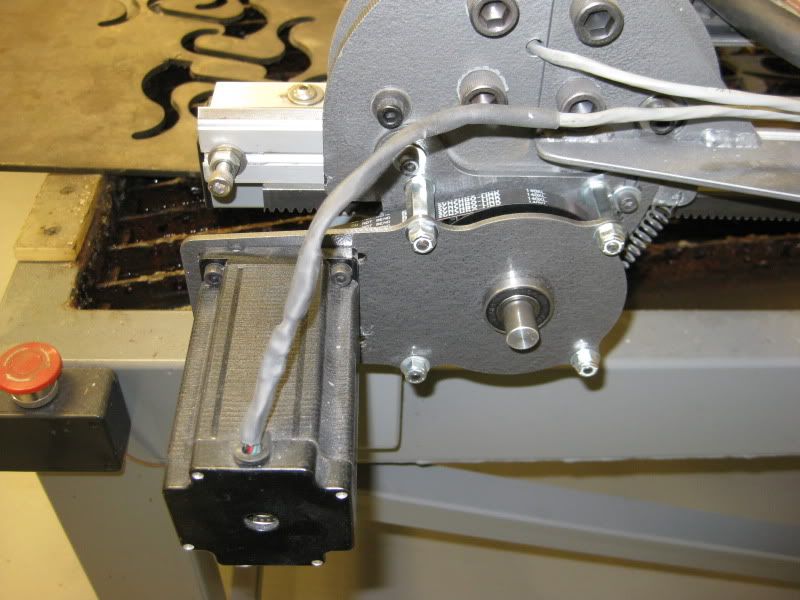

Im using Tulsa's Z axis, which consists of the stepper driving a gear rack directly. I was considering moving the steperr over an inch, and installing a large gear between the tiny gear on the stepper shaft and the gear rack....this should slow thw Z down considerably if im thinking right.

Someone correct me if im wrong on this?

--John

Results 1 to 9 of 9

-

07-03-2012, 06:55 AM #1

Registered

Registered

- Join Date

- Dec 2011

- Posts

- 0

Gear reducing Z axis (Tulsa's Z axis)

-

07-03-2012, 09:29 AM #2

Registered

Registered

- Join Date

- Jan 2007

- Posts

- 49

gearing

If you install only one gear it is just an idler gear, it will reverse the direction of the rack and reduce the efficiency a bit, due to friction losses, but will not change the ratio, for that you will need two gears/pulleys or a gearbox of some sort.

One snag is keeping the extra backlash that gearing gives under control. A simple belt reduction system is good, but is sometimes a bit awkward to implement on a Z axis for space reasons.

I am using steppers with low backlash 10:1 gearboxes built in. I have also used 50:1 harmonic drives which have extremely low backlash, but are a bit slow for a router.

John

-

07-04-2012, 08:32 AM #3

Registered

Registered

- Join Date

- Dec 2011

- Posts

- 0

I did a little experiment (I felt like the mythbusters). My girlfriend helped me. I got an old motorcycle handgrip, about 1" dia and placed a ruler against it to represent the gear rack. One rotation of the hand grip moved the ruler 4.5".

Then i put the handgrip against once side of a a 8" wheel, and put the ruler against the other side of the wheel. Hence the handgrip represented the small gear, the wheel the large one, and the ruler the gear rack. While my girlfriend rotated the handgrip against the wheel, i held the ruler against the wheel to see how far it moved. To my amazement, the exact opposite of what i wanted to happen happened. The ruler moved 9".

Interesting stuff!

--John

-

07-04-2012, 09:33 AM #4

Registered

Registered

- Join Date

- Jan 2007

- Posts

- 49

There's always one, well in this case two

I think the magic circle might suit you better than the mythbusters

-

07-04-2012, 01:05 PM #5

Registered

Registered

- Join Date

- Mar 2012

- Posts

- 140

I'm having the same problem you are with the sewing machine effect. Aparrently the resolution is not fine enough. my leadscrew is at 1in movement per 1revolution of stepper. I just posted on Candcnc yahoo group, title= " Jagged edges on THC first runs." , and Tom left me 2 responses which were very helpful. A few other guys did too. Check it out.

I'm gonna attempt to work with the leadscrew I have by tweaking a few settings. There's not a whole lot of room on the z axis on my machine to install a belt reduction or anyhing of that sort. My best options for a mechanical solution are to change out the linear actuator-change out the leadscrew in the actuator( i'm not even sure if thats possible or affordable) or install a stepper gear box.

Good luck.

Marcel

-

07-04-2012, 04:04 PM #6

Registered

Registered

- Join Date

- Mar 2011

- Posts

- 0

I just made my own gear reduction about 3:1 and works really good. I got my parts from mcmaster carr. I think maybe even 4:1 is better for the z axis. The gear reduction also holds the z axis in place when power is turned off.

-

07-05-2012, 07:57 AM #7

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

I made my own belt reductions also (not on the Z, since I have a K2 Z which uses a leadscrew). It wasn't terribly difficult or expensive to do...it's nice having a plasma table to make parts for my plasma table.

I used parts from Stock Drive Products.

Carl

Carl

-

07-08-2012, 01:26 AM #8

I wish I could make my unit work! I have a 570oz.in. Keling stepper on my Z driving a 2-start 8tpi acme lead screw and a 7.8 amp stepper driver running the motor. K2 copy mechanism. I've tryed THC rate from 5%up to 40% and no difference. The cut profile settings are as recommended, I am completely stumped why my Z won't do what it is supposed to do.

-

07-09-2012, 03:06 AM #9

Registered

Registered

- Join Date

- Dec 2011

- Posts

- 0

Actually, since switching to the hypertherm, my z seems to be working good!

--john

Similar Threads

-

DC Gear motor axis drive?

By leaveme in forum CNC Machine Related ElectronicsReplies: 1Last Post: 09-21-2010, 03:45 PM -

Reducing Gcode for simultation 4 axis

By pinguS in forum SolidCAM for SolidWorks and SolidCAM for InventorReplies: 3Last Post: 08-13-2010, 05:36 PM -

Loosing step more and more on X axis only after reducing the accl/velocity step motor

By Calico in forum DIY CNC Router Table MachinesReplies: 3Last Post: 04-10-2010, 01:23 AM -

acme 2 start rod vrs. gear up box on z axis

By drummer 1 in forum Linear and Rotary MotionReplies: 2Last Post: 02-08-2009, 01:38 AM -

gear box for x, y axis

By eloid in forum CNC Wood Router Project LogReplies: 0Last Post: 03-02-2007, 04:08 AM

Reply With Quote

Reply With Quote