I thought this would make cool thread. Let see those pictures of parts you have made. Just keep them to hobby, not for pay or parts your just proud of.

Here's mine:

The first 2 are of a RC pattern plane that is a gas to electric conversion. All the flat CF pieces were done on my PCNC1100.

The F7F Tigercat is an electric RC plane designed about 10 years ago. It's a pretty fast plane now with modern motors and LiPo batteries. The parts I made were the motor mounts and the retractable landing gear mounts.

Thanks for looking,

Barry

Results 1 to 20 of 48

-

07-03-2012, 04:43 PM #1

Registered

Registered

- Join Date

- Jul 2007

- Posts

- 131

Let see those hobby / not for profit parts.

Tormach PCNC1100, Mach 3 R3.043.037, MastercamX5 level 3.

-

07-03-2012, 05:21 PM #2

Registered

Registered

- Join Date

- Feb 2011

- Posts

- 605

Great thread idea. I'm just getting started on the part making journey with my machine, although not a Tormach - I've only done a handful so far.

Scope adjustment lever.

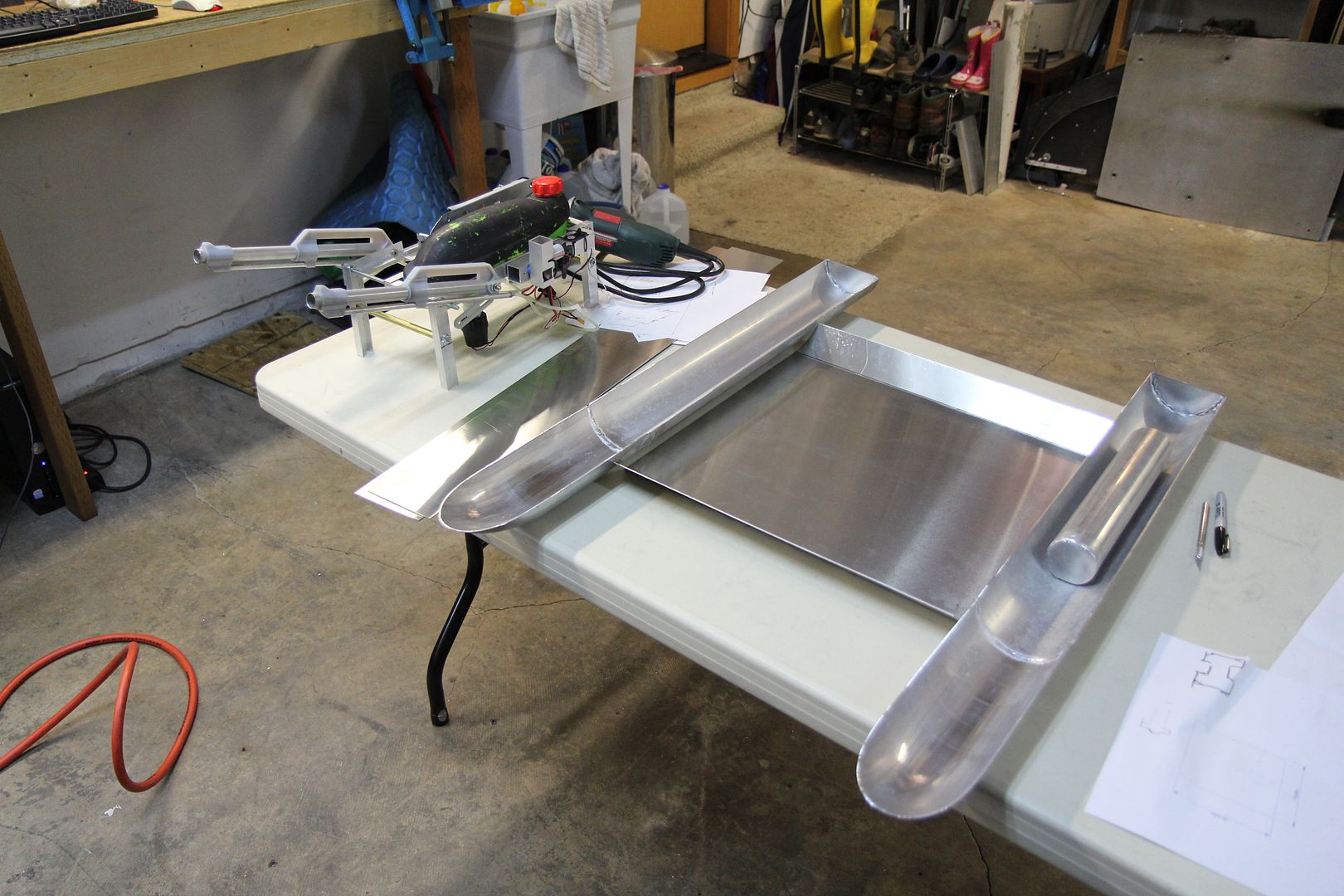

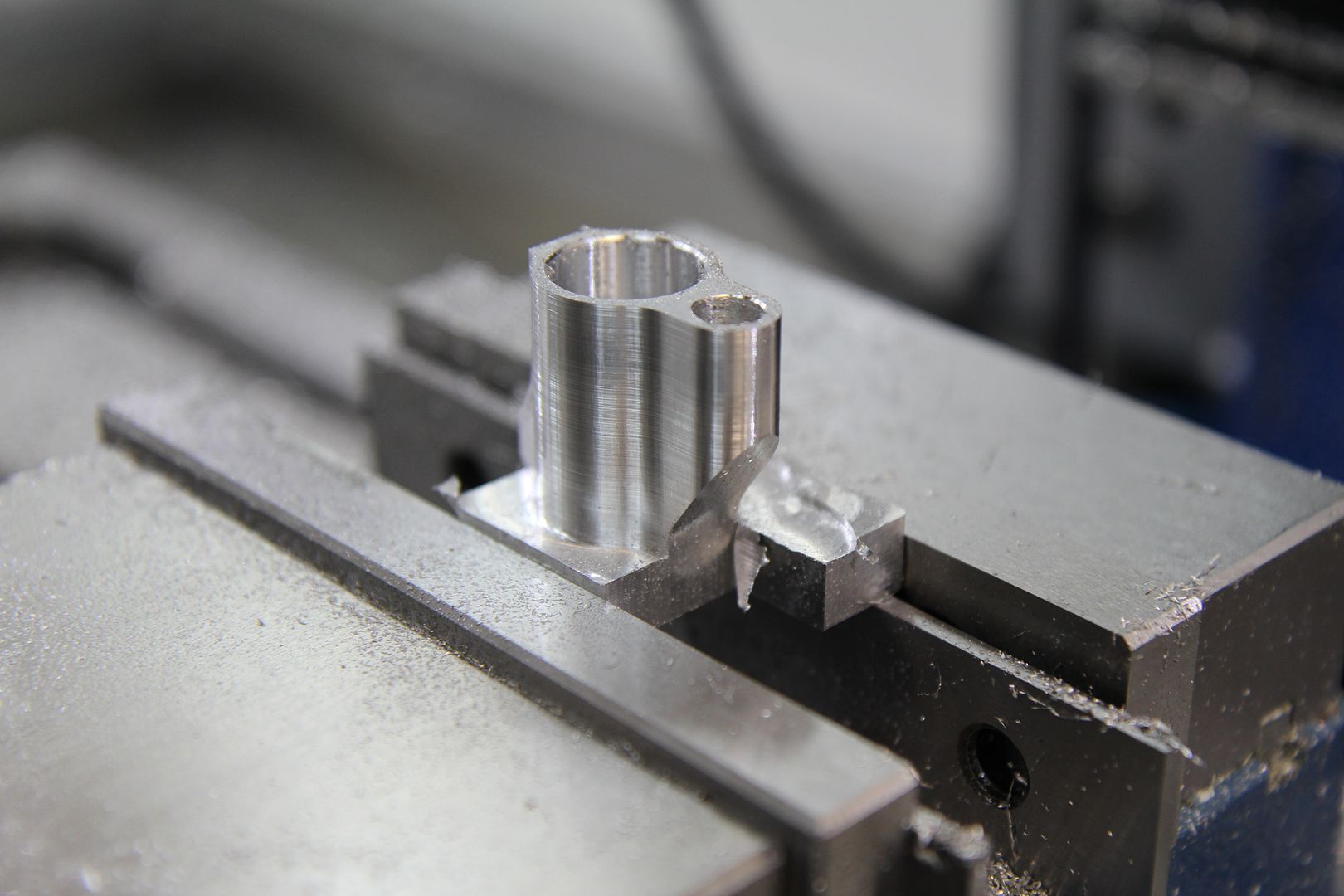

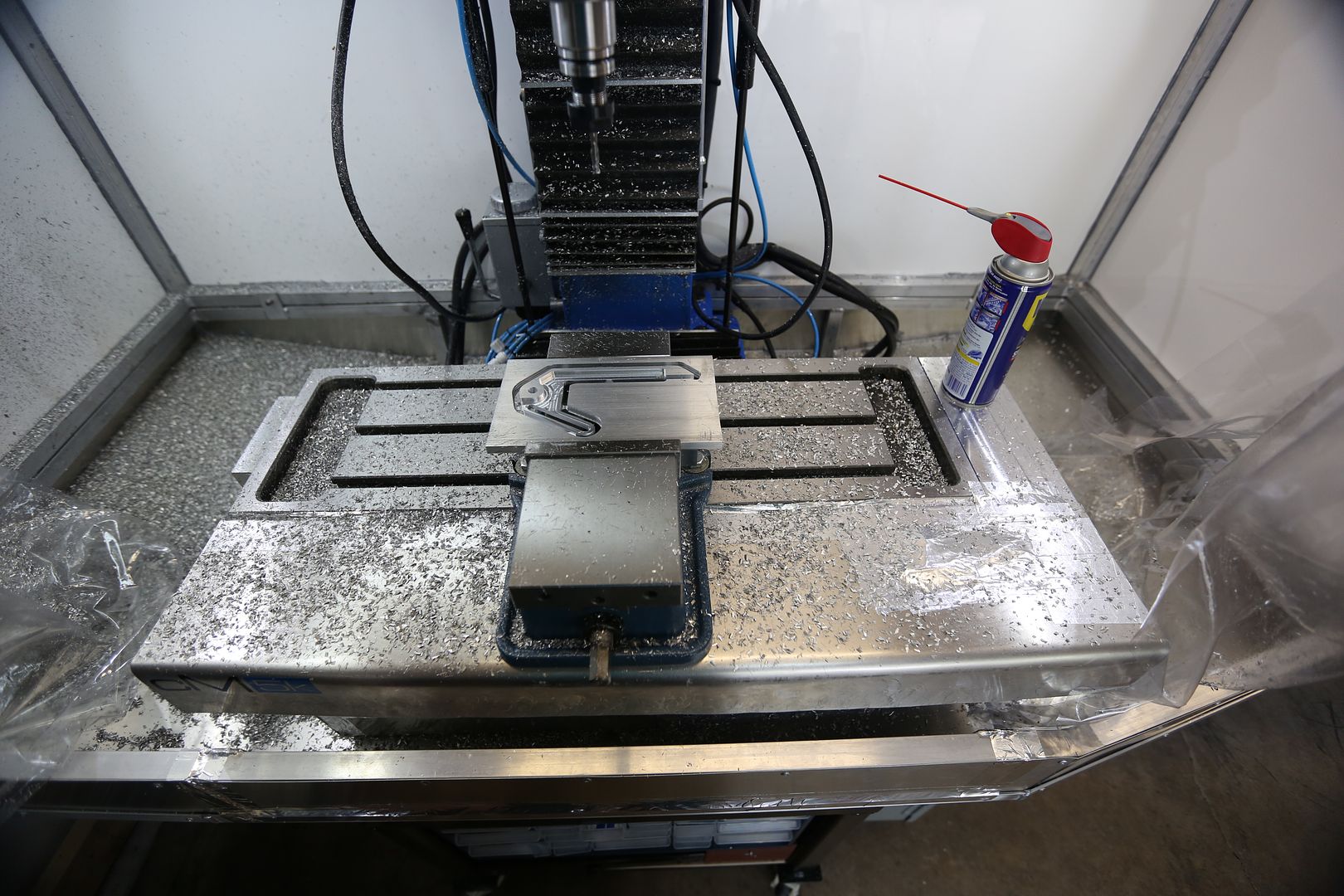

RC dual wielding flame thrower boat. Making all the barrel brackets and nozzles - you can see the proof of concept 3D printed parts in the first picture.

PM-45 CNC conversion built/run/sold.

PM-45 CNC conversion built/run/sold.

-

07-03-2012, 06:27 PM #3

Registered

Registered

- Join Date

- Feb 2008

- Posts

- 389

Nice looking parts you guy's!

Here are some parts and assemblies I have made with my PCNC770

A special tool to remove the fork caps on my motorcycle, I recently changed fork springs and fork oil and needed this to complete the project.

And a couple of model air powered steam engines.

A Elmer's #50

And Elmer's #37 "Grasshopper" engine.

I have a movie of the #50 on Photo Bucket but Photo Bucket is really slow right now, I'll add a link if anyone is interested. The #37 is about 90% done, just the little fiddly stuff takes a long time.

I am also about ready to start making chips on some aluminum top and bottom triple clamps/ assembly for a 1972 Triumph Bonneville that I am converting into a cafe bike. Here is a rendering of that assembly.

I'm just trying to decide on how I'm going to do the gauge cluster, switch panel and make some changes on the top clamp. I plan on making my own clipon's as well as rear sets and brake/ shifter linkage.

GerryCurrently using SC7 Build 1.6 Rev. 64105

-

07-03-2012, 09:03 PM #4

Registered

Registered

- Join Date

- Aug 2009

- Posts

- 294

-

07-03-2012, 10:02 PM #5

Registered

Registered

- Join Date

- Jul 2007

- Posts

- 131

I understand your question...I hear CF is as good for you as asbestos

What I do is use a 1/32 2 flute @ a very low RPM (5100) & feed. This keeps the dust from getting blown around. Also I use a product called DragonPlate.

It's CF sheets laminated to a hard ply wood core. When machined, it looks like the wood and glue mix up with the CF fibers and keep the dust from becoming air borne. For clean up I use a Shop vac with a HEPA filter.Tormach PCNC1100, Mach 3 R3.043.037, MastercamX5 level 3.

-

07-05-2012, 05:58 PM #6

Registered

Registered

- Join Date

- Dec 2010

- Posts

- 1230

Cool thread idea. I love the RC stuff! Especially the dual flame thrower... twice as awesome as one.

These parts are from my X3, but used TTS tooling Not as cool as the other stuff posted, buy may give some gift ideas since christmas will be here in no time.

Not as cool as the other stuff posted, buy may give some gift ideas since christmas will be here in no time.

First thing I actually made: plaque for some friends that I cut. Traced in Nicky Haden and their favorite local race track

A thank you coin for my motorcycle mechanic. Their company logo, rotor

and all.

Christmas ornaments

Modifying some wrong-size clip ons for a buddy

speeder handle for my vises

Wheelchair frame spreader I

made for a patient recently

The end of this video shows why he needed it.

[ame=http://www.youtube.com/watch?v=jUNDRCIgZbA&list=UUQNFF7xG2J4XqpSuhP6ewUA& index=1&feature=plcp]X3 CNC Mill - Wheelchair Spreader - Many ops - YouTube[/ame]

-

07-05-2012, 11:24 PM #7

Registered

Registered

- Join Date

- Jul 2007

- Posts

- 131

Nice parts so far.

jid2, That flame thrower boat sounds too cool. Hope to see a video when it's finished. Maybe you and Steve could have a on water dual

Gerry, Are the triple clamps so you can fit a modern set of forks and brakes to your Triumph?

Priddy, That coin is too much...very nice. Is that your own design?

Good video also, I'm always loking for new ways to hold odd shaped parts.Tormach PCNC1100, Mach 3 R3.043.037, MastercamX5 level 3.

-

07-05-2012, 11:35 PM #8

Registered

Registered

- Join Date

- Dec 2010

- Posts

- 1230

Thanks. The design was from a 2D JPEG I copied from their website, traced in Solidworks then programmed 2.5D with the M raised off the rotor, the box above that. Pretty fun using a 1/64" EM on a free part. LOL

Had to use an engraver to spot drill for all the holes in the rotor since the drill bit was smaller than the web on my spot drill

-

07-06-2012, 12:20 AM #9

Registered

Registered

- Join Date

- Feb 2011

- Posts

- 605

Trial run of death barge. Needs some tweaking, but the basic concept is there - 15 to 20 ft range.

PM-45 CNC conversion built/run/sold.

PM-45 CNC conversion built/run/sold.

-

07-06-2012, 12:39 AM #10

Registered

Registered

- Join Date

- Dec 2010

- Posts

- 1230

bwahahaha! THAT IS COOL

-

07-09-2012, 07:41 PM #11

Registered

Registered

- Join Date

- Jun 2012

- Posts

- 0

Nice...I might modify your ideas for some xmas gifts. What is the do you know what that material is called (the one with the black cover but white underneath)?

-

07-09-2012, 11:22 PM #12

Registered

Registered

- Join Date

- Aug 2009

- Posts

- 986

-

07-09-2012, 11:48 PM #13

Registered

Registered

- Join Date

- Mar 2012

- Posts

- 133

This is my none profit. but worth it.

-

07-10-2012, 12:57 AM #14

Registered

Registered

- Join Date

- Jul 2004

- Posts

- 595

-

07-10-2012, 01:42 AM #15

Registered

Registered

- Join Date

- Mar 2012

- Posts

- 133

Thank you. The first pic was a truck for a kid with cancer. I end up giveing most of these trucks away. Fun to build, Now I got the Tormach to make the wheels look more real, and making some of the parts. Every truck is diffrent. Each truck has walking rear tandums, working winch, also has a second wench in bed for the pulls string to pull the toy then wind it back up. All metal parts are food grade stainless, Has a dollar coin imbeded into truck. Food grade and waterproof glue, And all the wood is scraps from pallets or wood shops. I do test them, 2 miles behind a bike on the tar, 20 MPH into a brick wall. Down a flight of stairs, dropped of tables. For little kids, strings are shorter, less little parts ect, bigger kids, I add a few more parts like this truck.

-

07-11-2012, 11:01 PM #16

Registered

Registered

- Join Date

- Oct 2009

- Posts

- 67

This made me realize I need to take more pictures!

-

07-11-2012, 11:13 PM #17

Registered

Registered

- Join Date

- Jun 2012

- Posts

- 0

1/2 inch cubed dice. I give away many sets as gifts.

-

07-13-2012, 10:05 AM #18

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 1041

Still a work in progress

-

07-14-2012, 02:30 AM #19

Gold Member

Gold Member

- Join Date

- Apr 2007

- Posts

- 2580

-

07-14-2012, 02:31 AM #20

Gold Member

Gold Member

- Join Date

- Apr 2007

- Posts

- 2580

Similar Threads

-

Anyone from Perth Australia Selling Hobby CNC Machines Parts Ready to Assemble & Use

By guy2b1 in forum Open Source CNC Machine DesignsReplies: 6Last Post: 02-04-2012, 01:32 PM -

need hobby mill parts and fixtures?

By ihavenofish in forum Benchtop MachinesReplies: 39Last Post: 12-14-2011, 03:24 PM -

starting a non-profit

By charper in forum Community Club HouseReplies: 0Last Post: 10-27-2007, 02:09 AM

Reply With Quote

Reply With Quote