Results 41 to 60 of 78

-

08-22-2012, 06:47 PM #41

Registered

Registered

- Join Date

- Jul 2012

- Posts

- 0

-

08-22-2012, 07:20 PM #42

Registered

Registered

- Join Date

- Jul 2012

- Posts

- 0

I just ran Mach on the laptop and it says "Driver Successfully Initialized." Does that mean I'm good to go or is there some other test that I need to do?

I ran a config check and under the Output Signals Check it said "Port for an Output found as not port 1 or port 2. Unless using ModBus, this is wrong. Pin for an Output found as not pins 1 - 9, 14, 16, or 17. Unless using ModBus, this is wrong."

That appears to be more of an issue with where the port is located than the hardware of the computer.

Edit: After changing to the correct port address and running the config check no errors were found. I have the ACPI of my laptop setup for Standard PC which supposedly fixes the shuttering issue you mentioned. We will see.

-

08-22-2012, 08:27 PM #43

Member

Member

- Join Date

- Apr 2003

- Posts

- 354

There's a separate drivertest.exe you need to run. I think the "Driver Successfully Initialized" message comes up each time you launch Mach.

-

08-29-2012, 07:56 PM #44

Registered

Registered

- Join Date

- Jul 2012

- Posts

- 0

-

08-29-2012, 08:30 PM #45

Member

Member

- Join Date

- Apr 2003

- Posts

- 354

I use an older version of TurboCAD Deluxe...v9 I think. I've used it for years and it does way more than I need. Got it online for $25.00 some years ago.

HOWEVER, I'm having trouble getting it to play nice with CAD2Lathe, the inexpensive lathe CAM program I have. I'm still in the lower part of the learning curve with it but Draftsight (free 2D ACAD clone by the makers of Solidworks) is said to work well with it should you choose to go that route. If you're familiar with AutoCAD, you'd be right at home with it.

My budget for this stuff is limited and so far am having trouble with lathe CAD/CAM on the cheap. All the jobs I've run so far have been hand written but some upcoming work I hope to get will need CAM and that's when I'll have to get serious about learning it.

-

09-01-2012, 04:15 PM #46

Registered

Registered

- Join Date

- Jul 2012

- Posts

- 0

I get the following error code when I try to run the drivertest.exe

"Could not locate missing vectors."

I've done some experimenting with DraftSight and I'm definitely having fun. I need to figure out how to set the origin and how to work LazyCam better so that the G-code actually comes out readable by Mach 3. Any tips on good books similar to Tabletop Machinist except on the CAD/CAM topic? I think I have the CAD part figured out (I used to do a lot of 3D modeling, so it's pretty similar), it's just the CAM and machine interface that I am struggling with.

Next step is finding a spindle encoder and figuring that out!

-

09-01-2012, 06:08 PM #47

Member

Member

- Join Date

- Apr 2003

- Posts

- 354

Did a quick search on the Mach Support forum and there are many references to "Could not locate missing vectors." Sounds like you had the Mach program running when you executed drivertest.exe. Close out Mach & try again; drivertest is a stand-alone PC analysis app.

I'm glad you're getting familiar with Draftsight...you can teach me when you get good with it.

I truly understand the CAM/machine struggle as that's a thorn in my side as well. The simple jobs I've run so far have all been coded using bits & pieces from Mach wizards or hand coded using coordinates laboriously transferred from a CAD drawing. Watch out using LazyTurn as it was never finished and is limited in what it will do. There's a sub forum on the Mach Support site that might help you. LazyTurn

I use a CNC4PC C3 spindle index pulse card. It works great and is pretty cheap. CNC4PC

-

09-01-2012, 06:13 PM #48

Member

Member

- Join Date

- Apr 2003

- Posts

- 354

By the way, the free .pdf downloads from the Mach site are great resources!

ArtSoft USA - Documentation

-

09-01-2012, 06:31 PM #49

Registered

Registered

- Join Date

- Jul 2012

- Posts

- 0

What is your photo transistor using as a pickup on your setup? I saw a guy on YouTube using a Homann with a piece of electrical tape on the spindle as the pickup.

-

09-01-2012, 07:44 PM #50

Member

Member

- Join Date

- Apr 2003

- Posts

- 354

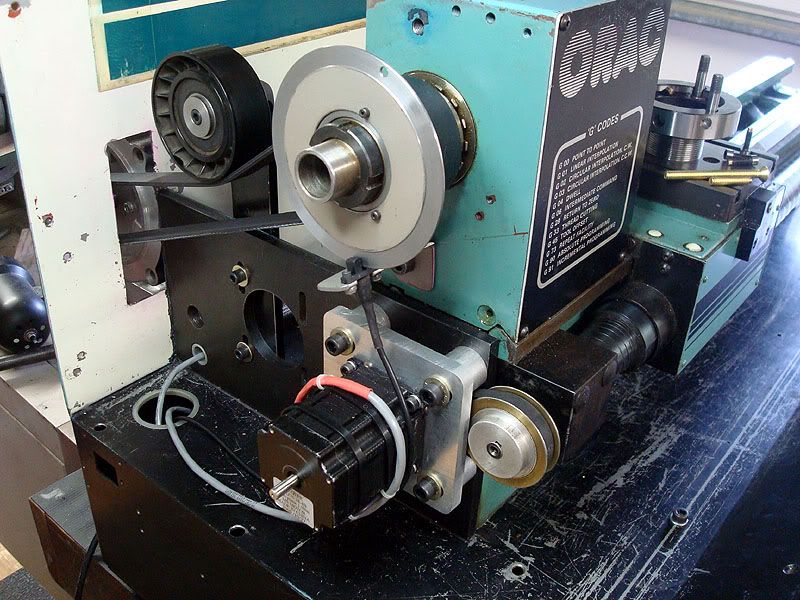

I made a 4" dia steel disc with a single #20 (.161") hole drilled in the edge...like this:

It's not real critical as to disc size, I used what I had lying around.

-

09-02-2012, 01:53 AM #51

Registered

Registered

- Join Date

- Jul 2012

- Posts

- 0

-

09-07-2012, 06:22 PM #52

Registered

Registered

- Join Date

- Jul 2012

- Posts

- 0

-

09-07-2012, 08:27 PM #53

Registered

Registered

- Join Date

- Jul 2012

- Posts

- 0

Okay, my only question now is where do I hook up the grounds? Should I wire them to pins 18 and 19 or the ground terminal which grounds to the metal on the cable. I'm thinking the ground terminal but I'm not sure which/if any/if all of ports 18-25 need to be grounded.

-

09-08-2012, 03:32 AM #54

Registered

Registered

- Join Date

- Jul 2012

- Posts

- 0

Okay I have everything hooked up. Originally when I went into Mach 3 to try to jog the motors they would make noise but not move. While attempting to move the Z motor after changing the settings I got BSOD and my computer crashed. Now when I go back into Mach the X motor will make noise but there is no longer any response from the Z motor. Is it possible that I shorted something and killed it? I did a quick visual inspection and nothing found, I guess I'll have to do more testing with the DMM.

These are my settings for x and z:

Steps per: 16000

Velocity: 20

Acceleration: 1

Step Pulse: 2

Dir Pulse: 0

I also have the "Sherline 1/2 Pulse mode" box checked.

-

09-08-2012, 03:43 AM #55

Member

Member

- Join Date

- Apr 2003

- Posts

- 354

Sorry 'bout the late reply Ben, been at the E.R. with wifey since 5:00 AM and am a little wacked out. She's resting finally now and I came home to get some sleep before going back in a few hrs. Hopefully things'll be better tomorrow.

AFAIK you definitely don't need Sherline mode as there are no Sherline electronics in your machine whatsoever. The lathe mechanical unit itself is all that's made by Sherline. You will have to restart the PC after changing modes I think.

Hope that helps 'cuz that's about all the brain power I have right now; sorry.

You're making progress; good luck!

-

09-08-2012, 03:55 AM #56

Registered

Registered

- Join Date

- Jul 2012

- Posts

- 0

-

09-08-2012, 07:42 PM #57

Gold Member

Gold Member

- Join Date

- Nov 2009

- Posts

- 4415

-

09-08-2012, 07:47 PM #58

Gold Member

Gold Member

- Join Date

- Nov 2009

- Posts

- 4415

If you can spin the steppers by hand there is something incorrect. Most likely not damaged just misconnected or misconfigured. I have never needed to use Sherline mode on any of my Sherlines (2 an A2ZCNC) but I am not running their electronics. I have a few G540's and a Hobby CNC Pro but they all are similar in set up.

-

09-08-2012, 08:05 PM #59

Registered

Registered

- Join Date

- Jul 2012

- Posts

- 0

-

09-08-2012, 08:22 PM #60

The P.P. common terminals are usually at earth ground due to the usual way of bonding the M.B. ground plane to the grounded P.C. chassis screws which is in turn grounded by the supply plug or wherever the power supply is fed from.

It doesn't hurt to take it to a ground star point as an option.

Al.CNC, Mechatronics Integration and Custom Machine Design

“Logic will get you from A to B. Imagination will take you everywhere.”

Albert E.

Similar Threads

-

Accel setting for Sherline Rotary cutting Wax?

By edferg in forum Mach MillReplies: 0Last Post: 03-28-2011, 08:31 PM -

Help with setting home on FC 3.0 and Sherline 5410

By kclank in forum FlashCut CNCReplies: 3Last Post: 05-26-2010, 01:04 AM -

Sherline Lathe & Bob Cad-Cam v23

By tip in forum Mach LatheReplies: 1Last Post: 08-09-2009, 01:47 AM -

7x CNC Lathe or sherline?

By Jason23 in forum Uncategorised MetalWorking MachinesReplies: 0Last Post: 09-10-2008, 06:08 AM -

What Sherline Lathe Accessories To Buy And When?

By Too_Many_Tools in forum Mini LatheReplies: 6Last Post: 10-11-2007, 05:46 AM

Reply With Quote

Reply With Quote