Can anyone help me identify the spindle in the pictures below. I think the VFD that came with my second hand CNC is Three phase and I only have one phase in my shop.

From what I can find, the spindle AND the VFD might be three phase only.

Here is the info I have:

.3Kw spindle 220v 9.5A 24,000 RPM Numbers on spindle: 0523-84506065

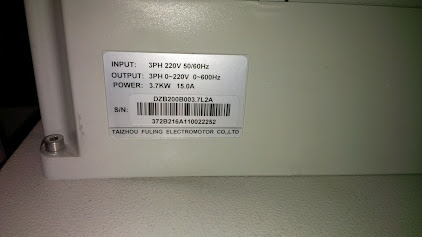

5. VFD Taizhou Fuling Electromotor co. (from side panel) input: 3PH 220v

Output: 3Ph 0-220 V

Power: 3.7KW 15.0A

DZB200B003.7L2A

I'm trying to determine if I just need to buy a VFD from Ebay and it will work with the spindle.

Any help or ideas would be appreciated.

Spindle:

https://lh4.googleusercontent.com/-s...B1840x3264.jpg

VFD :

Results 1 to 14 of 14

-

08-24-2012, 07:18 PM #1

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 24

Help identifying 3KW spindle and VFD

-

08-24-2012, 07:31 PM #2

Why not try the VFD with 1 ph into any combination or the RST input and see if the display comes up and it runs from the keypad?

Al.CNC, Mechatronics Integration and Custom Machine Design

“Logic will get you from A to B. Imagination will take you everywhere.”

Albert E.

-

08-25-2012, 04:35 AM #3

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 24

The funny thing is, the display is showing on the cabinet, but I have no idea on how to run the thing. I have been unsuccessful in finding a manual for the VFD.

Don't know how to rewire it for 1 phase, but will search around.

The previous owners said they never used the spindle.

Also, the water connectors (for lack of a better word) are not on the spindle.

Do you have any idea of where I can buy replacements?

They look like they just screw in.

-

08-25-2012, 05:01 AM #4

For single phase you would just wire in off of a 240v circuit and use two of the 3ph inputs, usually marked R-S-T.

They could be standard pipe thread?

Al.CNC, Mechatronics Integration and Custom Machine Design

“Logic will get you from A to B. Imagination will take you everywhere.”

Albert E.

-

08-25-2012, 11:47 AM #5

Registered

Registered

- Join Date

- Aug 2005

- Posts

- 91

The VFD's are always outputting three phase as that is what the spindle requires. The spindle is three phase. The VFD could accept a single phase and be outputting three phases although yours says that it is 3ph in so it might not work with a single phase.

More importantly if the VFD is not configured correctly you could plug it all in and do damage to the spindle. The spindle should not run for long without the watercooling working so I would fix that as well. I would only run it without water for a short test that it runs, not for doing any cutting.

It's possible that the vfd was never configured for that spindle or that it has lost it's settings so be careful plugging it all in and pressing go before you understand how to check the settings and configure them.

-

08-25-2012, 03:29 PM #6

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 24

Thanks Al and Jason, that clears it up a bit. Here is what came up (in Chinese..Google translated) when I entered the numbers on Google, here is what came up.

????????????????

Looking at the chart to 3KW spindles, they all require an input voltage of 380 volts 3 phase. researching phase converters, they will only put out a percentage over the input voltage, ex..I have 240 volt one phase, so the VFD's I've seen list they will output up to 280 volts three phase for the 3KW range. Seems this will not be enough for this spindle.

Am I reading this chart wrong or will the spindle work with a replacement VFD ?

If so, do you know which of the ebay VFD you would recommend?

I'm looking at this one :

3KW WATER-COOLED SPINDLE MOTOR 3KW INVERTER DRIVE VFD GRINDING ENGRAVING p | eBay

-

08-25-2012, 03:37 PM #7

Your VFD states 220v 3ph on the label, it will do no harm to power it up on 240v 1 phase in the manner I mentioned earlier, it is usually fairly obvious which is the 3 phase in and 3 phase out.

If looking at an alternative, one of the Hitachi VFD's on ebay are a good choice, with good support.

Some are designed for 1ph input.

For the link, I would buy the spindle separately and get a Hitachi VFD instead of the Huanyang VFD, they do not have all that a good reputation, and the manual is not all that hot.

What is wrong with using the spindle you have?

Al.

.CNC, Mechatronics Integration and Custom Machine Design

“Logic will get you from A to B. Imagination will take you everywhere.”

Albert E.

-

08-25-2012, 05:34 PM #8

Registered

Registered

- Join Date

- Jan 2010

- Posts

- 35

-

08-25-2012, 08:22 PM #9

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 24

-

08-25-2012, 10:11 PM #10

Registered

Registered

- Join Date

- Jan 2010

- Posts

- 35

-

08-29-2012, 06:27 PM #11

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 24

Thanks all, I tried dealing with the VFD that was installed but it was too much of a pain. Wouldn't accept settings, etc.

On another note, the 3KW spindle didn't have the metal water inlet fittings.

Can you recommend a place to get replacements?

-

08-29-2012, 06:52 PM #12

Are they taper (pipe) thread or parallel thread?

Have you checked if it is NPT etc?

Reference guide to selecting the size of pipe thread. and some TERMS - S-10 Forum

- S-10 Forum

Al.CNC, Mechatronics Integration and Custom Machine Design

“Logic will get you from A to B. Imagination will take you everywhere.”

Albert E.

-

08-30-2012, 10:30 PM #13

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 20

FZB200 FuLing

I've got a DZB130, a nice thing with vector control working like a charm on RS485 in modbus RTU.

Unfortunately your DZB200 doesn't have vector control. PM me if you want your manual.

-

09-06-2012, 05:26 AM #14

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 24

Update:

I purchased the Huanyang 3kw VFD from Ebay and the spindle works perfectly.

It seems the the cabinet containing all the drivers, VFD, etc, was not grounded...in any way that I could see. The ground wire coming in from the 220 volt supply had been cut short and not used???

Found this out by mistake, I had an arm resting on top of the cabinet and touched the machine and got a mild shock...consistently. I measured the voltage and it was 70 volts...unbelievable.

This could explain how the computer that came with it, one of the driver motors and the VFD were blown...just guessing here.

Either way I grounded the cabinet, measured voltage and 0 volts now showing. However, it still leads me to wonder and will have to trace where that leaking voltage is coming from.

Very happy it was just the VFD and NOT the spindle.

I really want to thank you guys for your replies, this is the best forum.

Also, on the water fittings, I'm thinking about tapping the holes to standard thread rather than try to chase down the metric fittings of the chinese spindle.

Anyone see any issues with that other than being careful with the filings getting stuck in the water ways?

Similar Threads

-

Identifying spindle bearings

By ddgman2001 in forum FadalReplies: 6Last Post: 05-22-2011, 01:45 AM -

Help Identifying the spindle speed proximity sensor

By Jim Caudill in forum HURCOReplies: 6Last Post: 01-24-2011, 06:18 PM -

Need help identifying a huge CNC Spindle Motor

By cheetahcnc in forum Uncategorised MetalWorking MachinesReplies: 8Last Post: 03-24-2010, 05:04 AM -

Need help identifying a Gilman Spindle Taper/Mount

By cheetahcnc in forum Uncategorised MetalWorking MachinesReplies: 1Last Post: 03-23-2010, 04:32 PM

Reply With Quote

Reply With Quote