Here's a little something I put together for my 80mm chinese spindle. I guess you know the type, 20,000rpm, comes with an ER11 collet on the end.

Its only as far as proof of concept testing, but it works very well so I thought I'd share.

The retention system uses the spindle motors own drive to tighten and loosen the locking nut (which will be held in place by a simple locking pin solenoid).

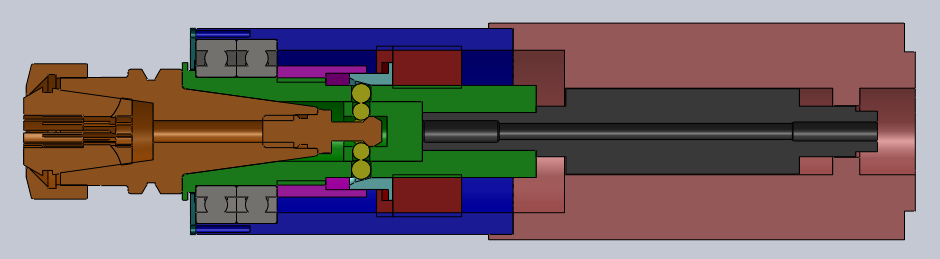

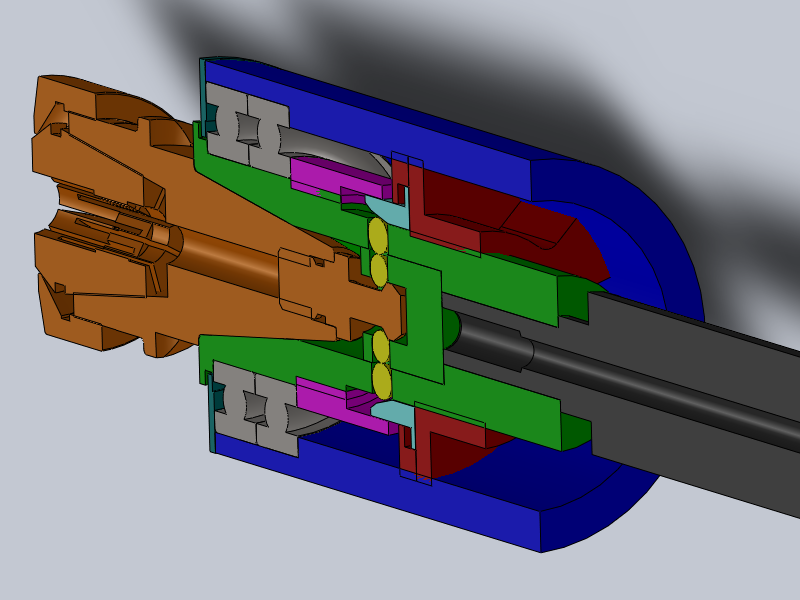

First I'll get the overview shots out of the way...

And a few videos:

Showing the tightening mechanism at work

and the retention force

Now the working principals.

Taper (green), toolholder and stub (bronze), locking balls (yellow), locking nut (red), and locking wedge (light blue) are the ATC parts. The rest is all pretty standard stuff.

Between the Taper and locking nut is a 2mm pitch thread. The locking nut has two drive (locking) dogs which (with a pin) lock the nuts rotation to the housing but allow it to move up and down the axis. This enables the locking nut to both pull and push the locking wedge up and down the spindles axis. When the locking taper is pushed down, the forces the balls inwards, which presses the tool holder stud upwards due to the contact angle. The tapers on the tool holder stud mean when the locking wedge is removed it will push past the balls easily.

I can upload CAD files, and give more detail on the manufacture (order of operations is important to reduce runout) if people are interested.

On a personal note, I reckon this is good enough to put into manufacture and go to hardened steel parts instead of aluminum like I used. However I'm a bit low on time an money so I'm just making it open source instead. Of course if anyone else wants to make one or more for yourself or others, just go for it. And if you think the designs are worthy of a donation PM me for paypal details, it'd be nice to afford more than one tool holder for my ATC setup

Results 1 to 20 of 40

Threaded View

-

10-06-2012, 05:40 AM #1

Registered

Registered

- Join Date

- Jul 2012

- Posts

- 49

Cheap and Simple ATC for Chinese Spindle

Similar Threads

-

Cheap 1500W Chinese spindle, experiences?

By matth in forum DIY CNC Router Table MachinesReplies: 1343Last Post: 06-07-2016, 07:44 PM -

Cheap and Simple

By tahwos in forum Stepper Motors / DrivesReplies: 8Last Post: 06-11-2013, 03:05 AM -

Cheap chinese spindle modifications - Generic

By speedydumpster in forum Benchtop MachinesReplies: 1Last Post: 03-28-2013, 04:28 PM -

Porter Cable or Cheap Chinese Spindle?

By 777funk in forum DIY CNC Router Table MachinesReplies: 3Last Post: 01-21-2011, 08:15 PM -

Connecting a hitachi VFD to a cheap Chinese Spindle

By zigmart in forum DIY CNC Router Table MachinesReplies: 5Last Post: 11-26-2010, 07:35 PM

Reply With Quote

Reply With Quote