Hello! This is my first post in what has been a great resource for me researching my CNC conversion. I really cant thank conrbinder, sagreen, and most of all crevicereamer enough for all the info!!

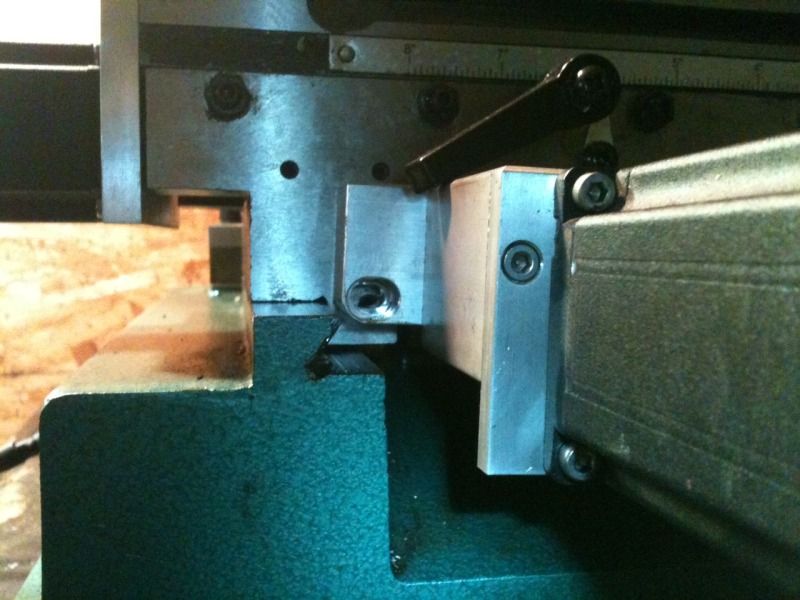

Now that I am in the final assembly process .. I have run into a bit of an issue. When I have the Y-axis ballscrew block tightened down to the base of the mill, the front plate of the motor mount does not want to line up with the saddle. I ensured that the locating pins were fully removed. If you take a look at the picture, when the ball nut is tightened to the base and the right side mount screw is snugged down, the left mount does not line up properly with the hole. It's possible to line them up when the Y axis is fully extended to the front .. but when I turn the Y ballscrew to move the saddle toward the column, it encounters increasing resistance and I can hear an odd clicking/pinging sound. It seems that the motor mount holes are a tad too high to me. Do you have any guidance or common issues like this?

Results 1 to 9 of 9

-

10-11-2012, 06:08 PM #1

Registered

Registered

- Join Date

- Oct 2012

- Posts

- 53

CNC Fusion Deluxe alignment issues?

-

10-11-2012, 11:29 PM #2

Registered

Registered

- Join Date

- Mar 2009

- Posts

- 388

I had exactly the same problem. I solved it by milling of the bottom side of the aluminum ball screw nut mount on the Y axis. Easy for me cause I have another mill to do the work with. When I spoke with CNCFusion about this, they had seen it before, and told me that its not uncommon for the mill to be manufactured with too high of a mount. I actually still hear a bit of noise when I run my ballscrew to its extents and expect that I am wearing my ballnut out.

Scott...Instructional Videos for CNC Guitar Building

http://www.rmgvideos.com

-

10-12-2012, 12:20 AM #3

Registered

Registered

- Join Date

- Oct 2012

- Posts

- 53

Wow thanks even more scott! I had considered that solution, but worried a little about damaging the ballscrew as i dont know how much extra meat is there at the bottom of the housing. How much did you take off? I dont have another mill, but i reckon i could do it on mine by using the stepper on the x and the gib lock on the y.

Another option i was considering was slotting the mount holes down a little .. But there really isnt much material down there so rigidity and durability migt be compromised.

Finally, i wonder if it would be possible to cut down the platform on he base itself. I havent looked at the material thickness yet .. But cutting it square would be difficult without any xy movement of the head. Maybe if the head came down in exactly the right spot. ..

I am a little bummed with this kind of fit on something i spent 1k on ... I know it is probably a change in manufacture dimensions on the mill manufacturer ... But if cncfusion gets back to me, i will probably suggest to them verticalslots on the front mount.

-

10-12-2012, 01:08 AM #4

Registered

Registered

- Join Date

- Oct 2012

- Posts

- 53

Nevermind all that babble!!

I think I will just drill two more sets of mounting holes higher on the plate and then drill and tap into the saddle so the mount is perfectly aligned. Luckily, I kept the manual quill so I can easily do the operations with the mill.

-

10-12-2012, 06:53 PM #5

Registered

Registered

- Join Date

- Dec 2010

- Posts

- 1230

[QUOTE=dogmeatk;1180351]Wow thanks even more scott! I had considered that solution, but worried a little about damaging the ballscrew as i dont know how much extra meat is there at the bottom of the housing. How much did you take off? I dont have another mill, but i reckon i could do it on mine by using the stepper on the x and the gib lock on the y.

Another option i was considering was slotting the mount holes down a little .. But there really isnt much material down there so rigidity and durability migt be compromised.

Finally, i wonder if it would be possibleo cut down the platform on he base itself. I havent looked at the material thickness yet .. But cutting it square would be difficult without any xy movement of the head. Maybe if the head came down in exactly the right spot. ..

I am a little bummed with this kind of fit on something i spent 1k on ... I know it is probably a change in manufacture dimensions on the mill manufacturer ... But if cncfusion gets back to me, i will probably suggest to them verticalslots on the front mount.[

QUOTE]

LOL. The issue is the mill, which was not designed to be cnc'd. For $1000 you/we are lucky it runs over half the time. Don't be bummed. If that is your only problem so far worth posting you should be thanking the conversion gods!!!!

For perspective my X3 made $983 this last weekend and $600 during the week last week. Heck, it has paid itself off (the whole conversion) about 4 times over in the last year not counting my oem products.

It runs on average 4hrs/day and has been for 14 months and holds 0.002" the whole time. I quote +/-0.005" to my customers and haven't had more than a few parts come back yet (half of those were from lack of care in set up/not getting a chip off the parallels . A few jobs required tighter tolerances and took a lot more effort and planning but I charged accordingly and even factor in spare tooling, and material to replace a mistake and the time to take a lot of care when setting up... And I'm still cheaper than their other quotes by 20-30% or more. Honestly I have gotten almost every single job I have bid and sometimes feel bad for charging what I do. BUT there are a lot of jobs I WONT bid. Like one right now that is 316 SS. The mill ops would be no problem, but but the ends are turned on the lathe and need a recess behind the threads with an inside radius on both corners or the recess... I dint think I can do it on the manual lathe without work hardening it so I sent it out with a 5% mark up. I touch nothing except an invoice and cash a check. Much less stress.

A lathe job I ran a few weeks back scared me because I was chucking and re machining finished parts that cost $3400 ea, 6 total. Quoted 1.5hr ea +$120 set up/pucker factor. Ran them all in about 4 hours with one $5 insert. That was a nice hourly rate/weeks pay.

Work through the hiccups and keep your eyes and thoughts on the goodies you want to make. Machining IMO is the single most rewarding hobby (soon to be full time job). I have had. And these machines are practically free for what you are getting. I it just helps to keep in mind you are using them in a manner they WERE NOT DESIGNED FOR. but they do a good job anyways.

Happy cutting, and welcome aboard!

-

10-12-2012, 07:51 PM #6

Registered

Registered

- Join Date

- Oct 2012

- Posts

- 53

Hey Shiddy, thanks for the perspective! I forgot to mention you in my shout-out, but your stuff has been super helpful to me in my research process. I know this thing will make me some good bucks once It is up and running

My qualm has more to do with the fitment of the CNCFusion kit and not the mill itself .. If they are aware of the fitment problem, a quick little redesign would have fixed it before he sent the parts to me. Anyway, most people seem to be getting really good service from them so I am not gunna throw a fit. I already know how I am going to make it fit, but if I knew I was going to be cutting up the mounts, I would have just made them myself while I still had the leadscrews and handwheels installed. I paid a little extra for the "plug-and-play" kit and could have permanently damaged my ballscrew nut if I wasnt this cautious. I don't mean to sound whiny and piddly, but I spent a little more on the kit for convenience .. that just didnt work out. Money is tight for me right now as I am finishing up my last quarter of college and i cashed in my 401k from the Army to buy the mill and the kit.

Anyway, thanks for the help dudes, I will post my results once I get my new hard drive for the compy rig.

-

10-16-2012, 07:59 PM #7

Registered

Registered

- Join Date

- Mar 2009

- Posts

- 388

Yeah, it sounds to me like both the up/down and left/right are problems with the Y mount, so CNCFusion picked the least common denominator with the Left / Right. I'm not sure...

Either solution would work. I do like your idea in that you could fine tune the adjustment over the travel of your mill. i.e. adjust for the best fit as opposed to taking a little at a time off of the ball nut mount. Like I said, I dont think mine is perfect cause I still hear noise on the Y axis. X is perfect. I removed like .18" from mine if I recall.

Scott...Instructional Videos for CNC Guitar Building

http://www.rmgvideos.com

-

11-01-2012, 04:51 PM #8

Registered

Registered

- Join Date

- Oct 2012

- Posts

- 53

Okay, all fixed up now using the mount plate I already had. What I ended up doing was using the two locating pin holes above the mounting bolt holes. I drilled them out to 5mm then tapped them for the M6. Before doing so, I scribed the locations into the motor mount plate when the ballscrew was tightened down and properly aligned. Then I redrilled the holes in the right location,

It's not super pretty, but my Y works butter smooth now

-

04-28-2013, 04:49 AM #9

Registered

Registered

- Join Date

- Mar 2012

- Posts

- 77

Hey dogmeatk,

Yes, I was hoping for plug-and-play too, not with the entire process, but with the $1,000 kit. None of the 3 CNCFusion x & y brackets line up. The Sieg holes are not even. My y motor mount is on an angle, the right x-bracket is offset from the table, so I have to put washers in to fill the space between the bracket and the table, the left x-bracket doesn't line up, so there is misalignment of the helical coupler, etc. in the end, my x-axis seizes up, especially as it approaches the zero half of travel. Even when it isn't siezed, I can hear a pulsing due to the incorrect alignment of the x motor mount, the x-motor, the helical coupler, etc. Honestly, it's a bit of a dog's breakfast... I'm thinking it would have been easier to measure, design and manually mill the brackets, so everything would align first time. The only part that worked seamlessly is the z-axis. Sadly, that is the only one that isn't visible. Very disappointing actually.

I'll be emailing Michael about this, and report back to you re: his solutions.

Any ideas would be greatly appreciated.

Similar Threads

-

CNC Fusion Deluxe Kit Instructions?

By peterpan84 in forum X3/SX3/G0619/G0463Replies: 14Last Post: 02-26-2012, 05:56 AM -

CNC Fusion Deluxe X3 Backlash

By LazyMan in forum X3/SX3/G0619/G0463Replies: 21Last Post: 09-24-2011, 10:31 PM -

Q on CNC Fusion Deluxe Y ballscrew for X3

By rezcar in forum Benchtop MachinesReplies: 3Last Post: 12-20-2009, 01:36 AM -

SNEAK PEAK: CNC Fusion X3 Deluxe kit

By wisp in forum News AnnouncementsReplies: 17Last Post: 03-10-2009, 05:01 AM -

CNC Fusion X3 Deluxe Kit Backlash Issues

By dneisler in forum Benchtop MachinesReplies: 28Last Post: 09-25-2007, 10:39 PM

Reply With Quote

Reply With Quote