I used it before reconditioning the big mill for the flood coolant mainly because it had great comments here in the zone, it's not easy to find in Spain too but you know, i prefer paying a little more for something that works than trying to find a cheaper solution than in the end, it comes more expensive.

Katran, perhaps you should take a look at a misting coolant system, it makes less mess than flood and surely you'll be able to push harder (flame2)

Results 61 to 80 of 123

-

12-27-2012, 08:27 AM #61

Registered

Registered

- Join Date

- Dec 2011

- Posts

- 161

-

12-27-2012, 08:31 PM #62

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 118

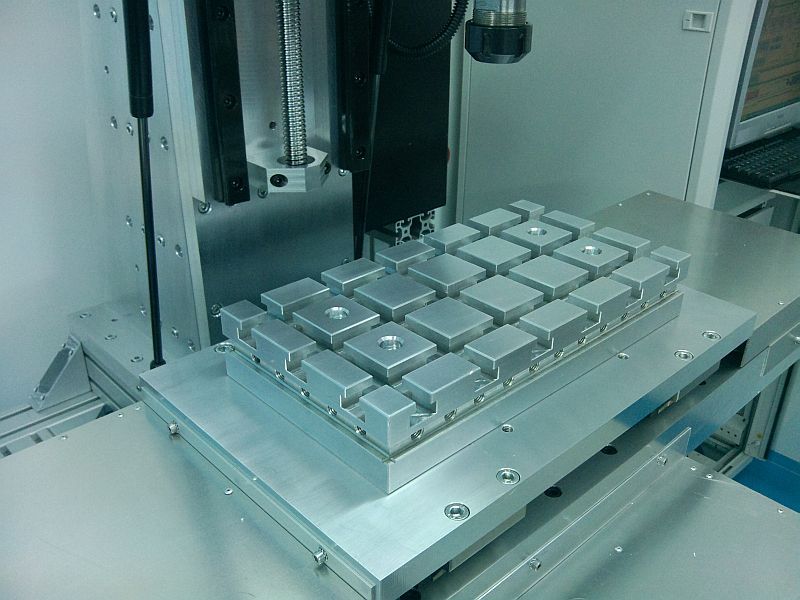

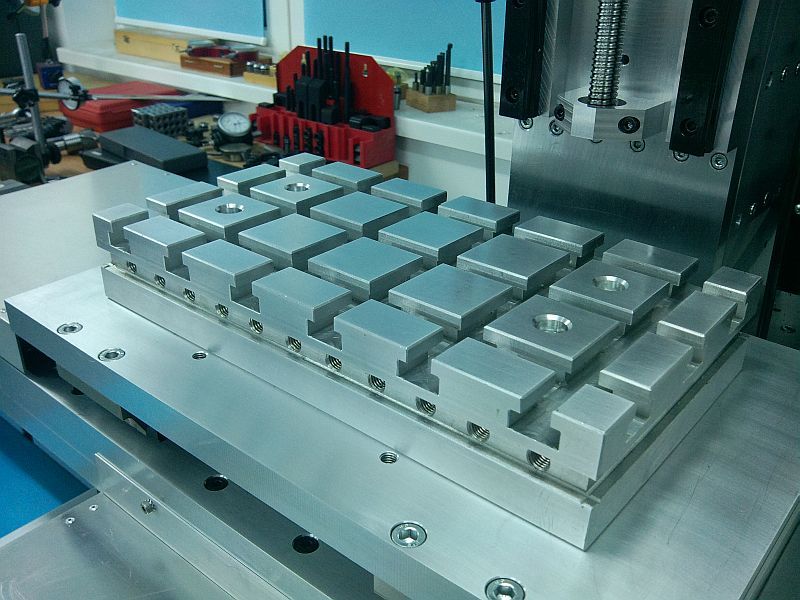

My subplate ... 6061 T6 aluminum , T-slot match for 3/8 clamping system .

Dimensions : 400mm x 200mm x 60mm .

...............................

-

12-27-2012, 08:57 PM #63

Registered

Registered

- Join Date

- Dec 2012

- Posts

- 0

Hi Katran,

as a first i really admire how your workshop is super clean!

I have a few questions related to your gorgeous milling machine.

0) which is is the max size of the workpiece which can be hosted on such mill ?

1) which is the grade of the ballscrew you used ?

2) which is the grade of the THK linear guides you used ?

3) you mention that you used isel ballscrew. I presume that isel is the brand of the ballscrew, right ?

4) do you think that filling the aluminium extrusion with epoxy granite would improve machine stability/stifness ?

5) do you plan to share drawings of such milling machine, for example on grabcad ?

Best regards,

Andrea

-

12-27-2012, 09:47 PM #64

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 118

Thanks .

0. max workpiece 450mm x 260mm x 250mm

1. Rolled ballscrew ISEL 2505 precision class C7 on Y and Z axis , precision

ground Leadscrew International 3210 on X axis .

2.THK SHS30 linear caged ball ( low noise , 4 way equal load )

3. ISEL is a german brand of ballscrews . True C7 , not like chinese crap

found on ebay ... I will upgrade later to G-Ten brand ( rolled C5 ) .

4. Yes , it would ... probably in the future I will do that ...

5. give me a message at "[email protected]" and I will send the archive

( neutral 3D / 3dm,step,iges ) . Files will be packed with WinRar .

happy ?

cheers

-

12-27-2012, 11:01 PM #65

Registered

Registered

- Join Date

- Dec 2012

- Posts

- 0

Hi Katran,

thanks for your availability, I've sent you an e-mail a few min ago

I noticed that you choose a "low noise" guide. Does "low noise" guides really makes less noise than "usual" guides ?

Moreover, I've got a question related to ballscrew accuracy (maybe it could be better to open a separate thread??)

You plan to upgrade from C7 to C5 ballscrews. Will such upgrade provide a significant improvement in the quality of machined pieces (accuracy of machined pieces). I do not have much experience, but i presume that vibrations of the spindle plays an important role in machining accuracy. Do you know is someone measured how accuracy of a machined pieces is a function of X,Y and Z ballscrews grade ? I think it could be an interesting test.

Thanks for sharing info about your machine.

Andrea

-

12-27-2012, 11:34 PM #66

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 118

SHS series rails from THK really make a lot less noise ... balls are caged

in some sort of plastic chain . It realy makes a difference ...

Upgrading ballscrews is a "must" . At the moment , machine error is

less than a thounsand of an inch ( 0.02mm ) , but with C5 ballscrews I

hope to get 0.01mm .

Vibration of the spindle is a big problem . That's why I bought a big ass

Colombo ( 10HP , 380V/3ph , 18,000rpm ) ...

Check your mail ... file ( rar archive ) sent .

Gabriel.

-

12-28-2012, 01:48 AM #67

Gold Member

Gold Member

- Join Date

- May 2005

- Posts

- 3920

-

12-28-2012, 06:09 PM #68

Registered

Registered

- Join Date

- May 2005

- Posts

- 35

I could not live without WD40 it is magic stuff so many uses.

-

01-04-2013, 11:32 PM #69

Registered

Registered

- Join Date

- May 2008

- Posts

- 8

Great stuff, well done you have inspire me again as myy project stalled many months ago (despite having acquired servos, drivers SHS rails and some of the extrusion) - my confidence that I could build a machine that was accurate and chatter-free enough as I had in mind (also aiming for .5 ) was in question. Having seen this project I am going to start back up :-)

If you are still willing to send files, I'd also love a set (I think you use Rhino? I have this and SW available anyway).

Thanks again for the inspiration!

-

01-05-2013, 06:10 PM #70

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 118

-

01-07-2013, 02:23 AM #71

Registered

Registered

- Join Date

- Jun 2010

- Posts

- 1414

WOW!! I love it!!!

-

01-13-2013, 03:25 PM #72

Neuer Benutzer

Neuer Benutzer

- Join Date

- Jan 2013

- Posts

- 0

Hello

Nice project there.

Can you tell me whats the X axis shaft diameter in the first picture in your last post?

And what's the workable area of that router.

Greetings.

-

01-13-2013, 07:27 PM #73

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 118

-

01-13-2013, 09:43 PM #74

Neuer Benutzer

Neuer Benutzer

- Join Date

- Jan 2013

- Posts

- 0

-

01-13-2013, 10:01 PM #75

Neuer Benutzer

Neuer Benutzer

- Join Date

- Jan 2013

- Posts

- 0

-

01-14-2013, 02:21 PM #76

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 118

-

01-15-2013, 01:34 AM #77

Registered

Registered

- Join Date

- Feb 2011

- Posts

- 423

Awesome build!

-

01-15-2013, 02:46 AM #78

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 118

-

01-22-2013, 08:16 PM #79

Registered

Registered

- Join Date

- Mar 2012

- Posts

- 0

Katran, I`m amazed about your cnc Mill. Please, could you tell me, What servos do you use in this progect(kW-? torgue Nm -? Price -? Model -?), servodrivers and controller?

May be you could make the photo of your electical box of the mill?

I`ve bought the milling machine, and would like to count everything to convertion.

Till today, I do not know how find the right power, torgue servo do i need to my mill?.......

Sorry for my English.

-

01-22-2013, 08:19 PM #80

Registered

Registered

- Join Date

- Jan 2007

- Posts

- 243

All I can say is AWESOME JOB! Beautifully done!

www.WebMachinist.Net

The Ultimate Online Source for Machinist Related Stuff!

Similar Threads

-

DIY aluminum vertical mill build

By sergizmo in forum Vertical Mill, Lathe Project LogReplies: 81Last Post: 09-07-2015, 04:59 PM -

400W Mitsubishi HC-PQ43 Servos - choice for Vertical mill build

By fcp in forum Servo Motors / DrivesReplies: 0Last Post: 01-05-2013, 11:51 PM -

Looking to build a simple vertical mill

By Crudeau in forum Benchtop MachinesReplies: 7Last Post: 10-27-2012, 01:13 PM -

Custom CNC vertical Mill build T-Minus 24:00

By cncgabe in forum Vertical Mill, Lathe Project LogReplies: 37Last Post: 03-31-2012, 02:18 AM -

Started build on CNC Mill. Lots of pics, sorry.

By EvanZ in forum Uncategorised MetalWorking MachinesReplies: 3Last Post: 02-17-2008, 02:24 PM

Reply With Quote

Reply With Quote