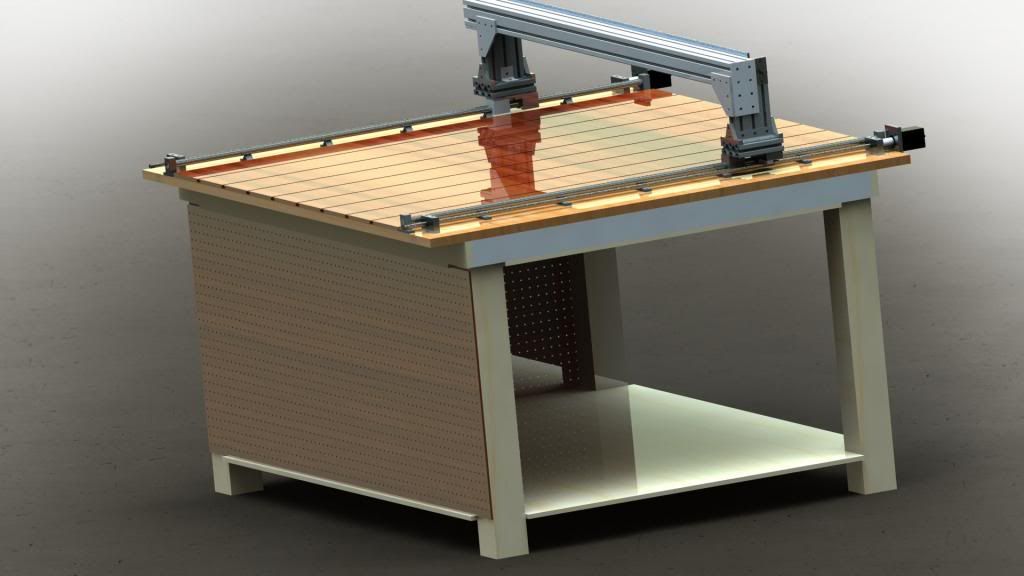

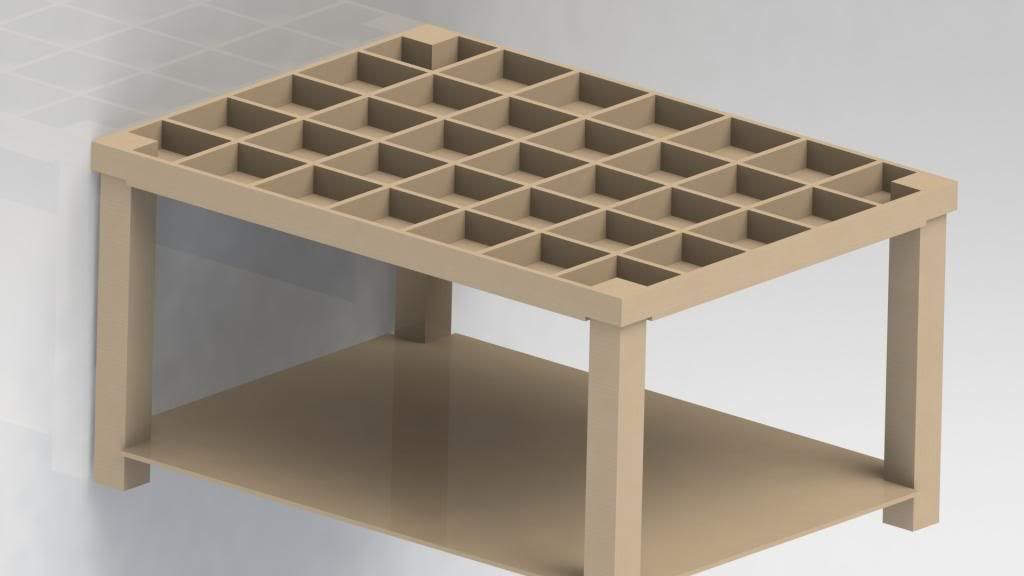

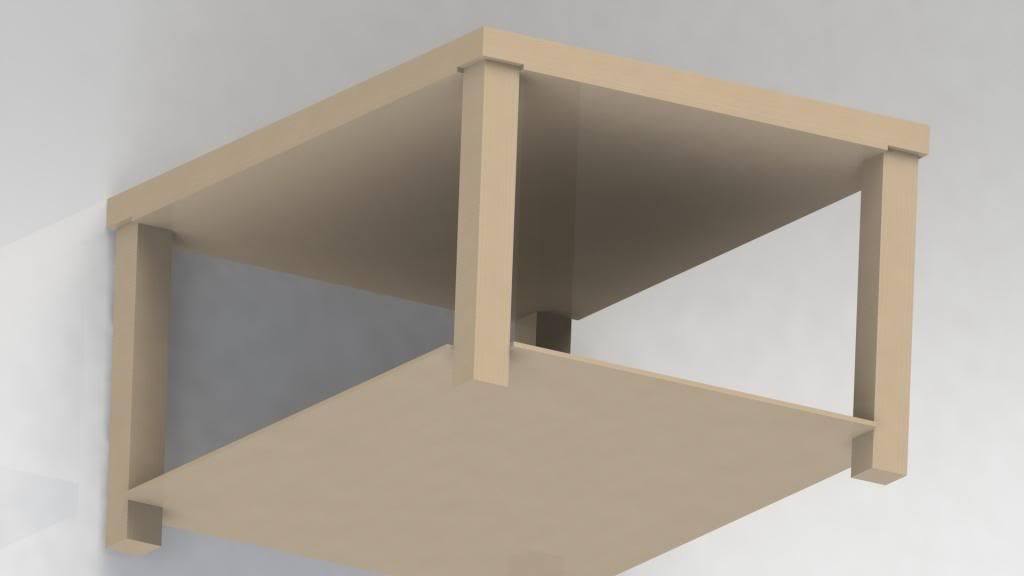

i got some more drafting made today, going with a torsion box style table, however it will not have a bottom until i get everything done, then it will be a removable bottom, think on two sides ill put peg board for not only functionality but also strength, then the other two sides will hold all the electronics and whatever else i need

Results 61 to 74 of 74

-

12-17-2012, 05:18 AM #61

Registered

Registered

- Join Date

- Nov 2012

- Posts

- 59

-

12-17-2012, 05:20 AM #62

Registered

Registered

- Join Date

- Nov 2012

- Posts

- 59

also its not a full torsion box as i left about 4 to 5 inches on each side open due to having to access bolts, do you think this will b ok my table is about 1.25" thick

-

12-17-2012, 05:46 AM #63

Registered

Registered

- Join Date

- Nov 2012

- Posts

- 59

heres what i have so far

-

12-20-2012, 08:53 AM #64

Registered

Registered

- Join Date

- Nov 2012

- Posts

- 59

been working on the z axis stuff, heres some pics, also the last pic is a possible counterweight idk lemme know what u thinnk

-

01-04-2013, 07:39 AM #65

Registered

Registered

- Join Date

- Nov 2012

- Posts

- 59

well havent got much done since the holidays hoping to get back on it in the next week or so

heres a pic of the completed machine for the most part

-

01-04-2013, 09:26 AM #66

Member

Member

- Join Date

- Apr 2007

- Posts

- 1955

You can get a feel for the flex that will be seen in the Y gantry pretty easily. Take a piece of the planned support (the 8020) the same length as your plan.

Make it a sort of balance beam on a couple of bricks and attach a dial caliper that just touches the floor.

Have a friend stand in the middle of the beam and measure the deflection and ratio this as if they weigh 100 lbs.

(example, if they weight 200 lbs, then divide the reading by 2)

It isn't a perfect method, but it is a good indicator of the "best" results you can achieve with your router, regardless of whatever else you do.

-

07-25-2013, 04:39 AM #67

Registered

Registered

- Join Date

- Nov 2012

- Posts

- 59

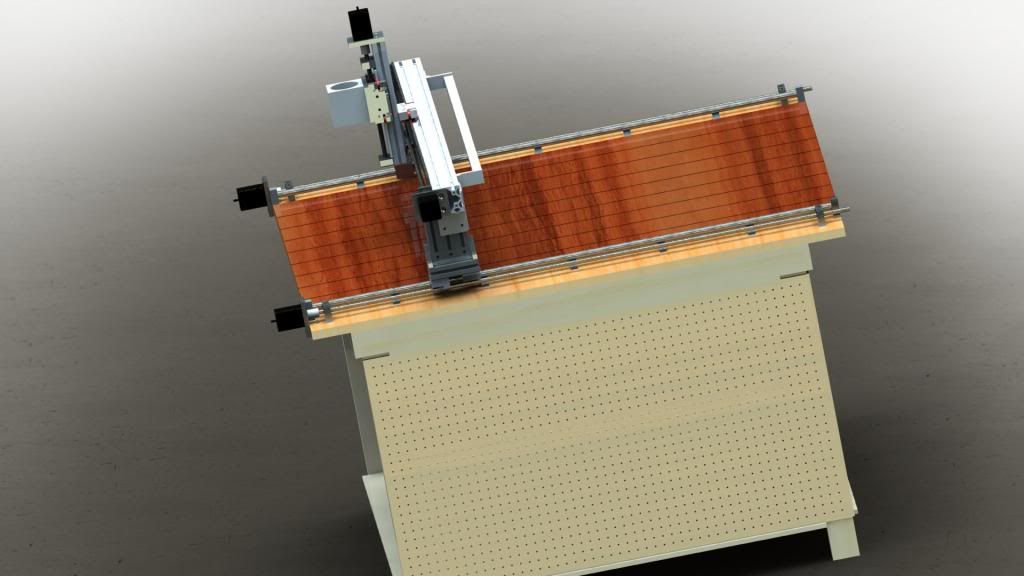

Hey guys I Know Its Been Forever!!!! But i Finally am Making slow process on the CNC im designing, and im pretty thrilled at how everything is actually coming together just as the 3d model I drew in solidworks. I still have a very long way to go but theres no turning back now. still gotta get the rest of the 8020 brackets for the gantry

Used a cnc to route my table and drill all the holes.

still have to make the rest of the center rail mounts ( i have to mill them)

Heres some pics of the progress

-

07-25-2013, 07:19 AM #68

Registered

Registered

- Join Date

- Nov 2012

- Posts

- 59

-

07-30-2013, 06:14 AM #69

Registered

Registered

- Join Date

- Nov 2012

- Posts

- 59

-

03-08-2014, 11:16 AM #70

Registered

Registered

- Join Date

- Nov 2012

- Posts

- 59

-

03-08-2014, 10:29 PM #71

Registered

Registered

- Join Date

- May 2007

- Posts

- 56

Looking good

I've just resurrected my old project that I started years ago and didn't get round to finishing. Give me another 5 or 6 years and I might have it doing something lol.

I've just resurrected my old project that I started years ago and didn't get round to finishing. Give me another 5 or 6 years and I might have it doing something lol.

-

03-09-2014, 05:06 AM #72

Registered

Registered

- Join Date

- Nov 2012

- Posts

- 59

-

03-09-2014, 10:58 AM #73

Registered

Registered

- Join Date

- May 2007

- Posts

- 56

I've not really been discouraged, just distracted

I've had a customer ask me to build him something fairly simple with steppers / belts etc and it has renewed my interest in getting it all finished. I think once you've got the bug, you never lose it

I've had a customer ask me to build him something fairly simple with steppers / belts etc and it has renewed my interest in getting it all finished. I think once you've got the bug, you never lose it

-

05-18-2014, 04:08 AM #74

Registered

Registered

- Join Date

- Nov 2012

- Posts

- 59

Re: partial 80/20 build using some easy to find parts

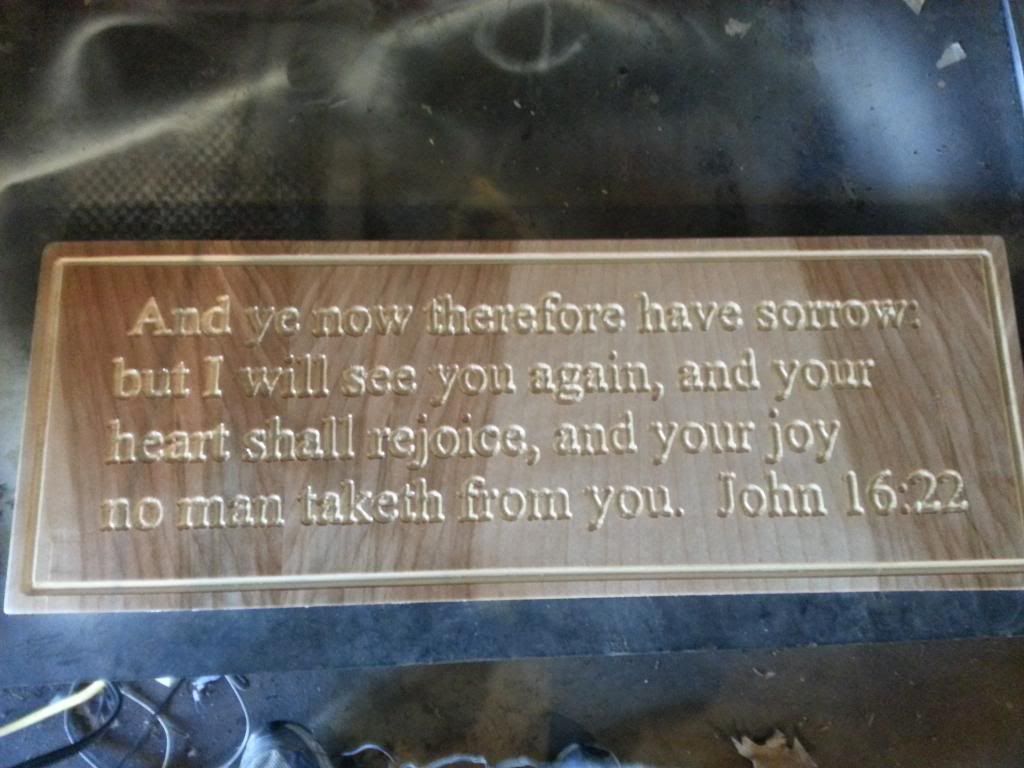

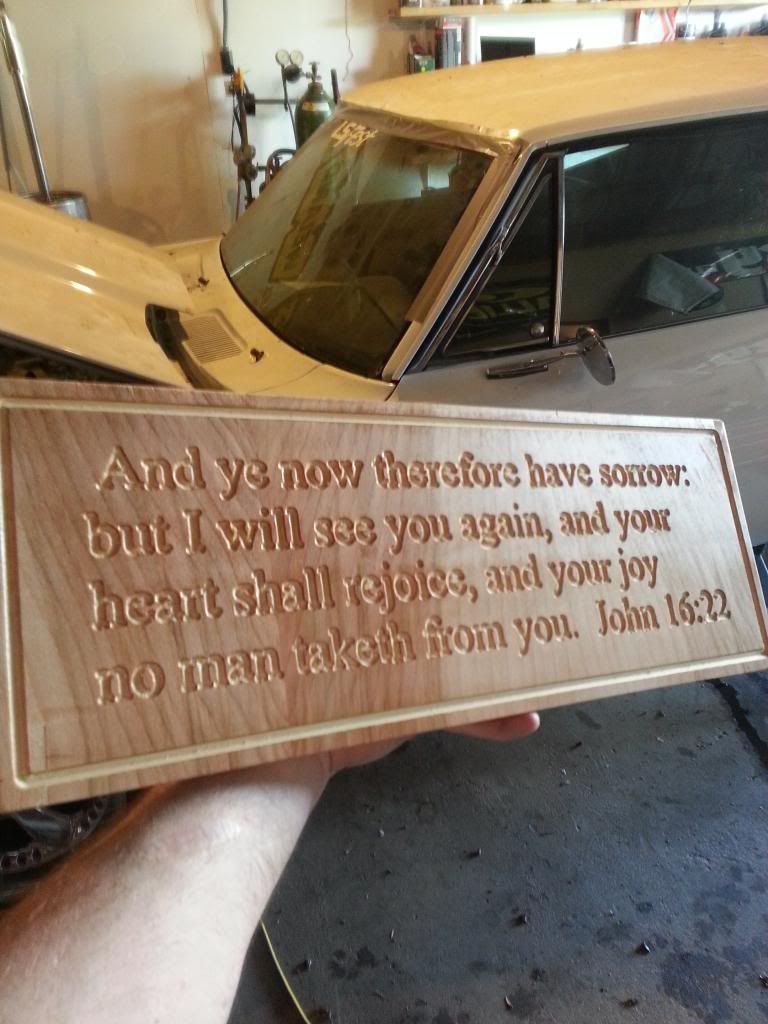

Thought id share a few things ive been playing with on my cnc machine, still learning and what not but a good start.

First is a plasma cutter template i cut out while designing a four link suspension for my car.

here is an attempt at the harley davidson logo still needs work

Here is a scripture plaque i cut for a friend which was also my first paying job lol

And here is a mothers day card before it was done i made for my mom.

Similar Threads

-

DIY BUILD. WHERE TO FIND PARTS IN CANADA

By Mikemann55 in forum Want To Buy...Need help!Replies: 4Last Post: 01-24-2017, 05:00 AM -

Easy Parts?

By 03ram2wd in forum Mini LatheReplies: 2Last Post: 12-17-2010, 01:50 AM -

Build Question - Partial machine, how do I complete?

By jross in forum DIY CNC Router Table MachinesReplies: 6Last Post: 11-04-2008, 01:48 AM -

...to find a machine or someone to build parts

By dabckid in forum Want To Buy...Need help!Replies: 2Last Post: 05-31-2008, 09:25 AM -

Easy way to find the radius?

By turboboy in forum MetalWork DiscussionReplies: 7Last Post: 09-27-2006, 03:20 AM

Reply With Quote

Reply With Quote