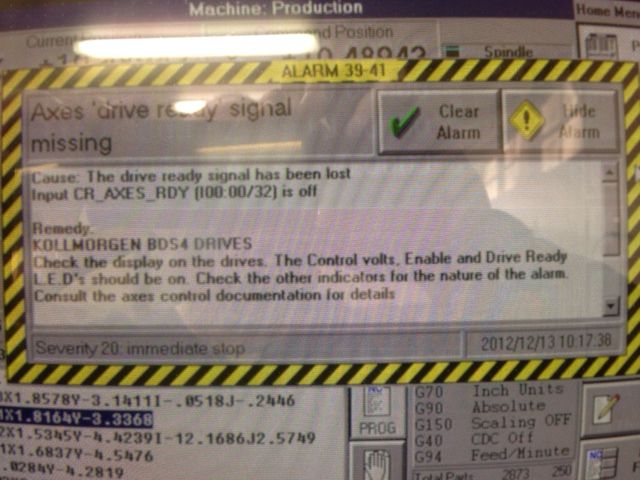

This alarm has came up 3 times so far today and I really dont know whats going on. HELP...

Results 1 to 16 of 16

-

12-13-2012, 04:27 PM #1

Registered

Registered

- Join Date

- Oct 2011

- Posts

- 205

Axis "Drive Ready" Signal Missing

-

12-13-2012, 04:39 PM #2

What shows on the drive status LED's?

It appears you are losing the drive ready signal back to the controller, either momentarily or completely?

This could be momentary O/L etc.

Al.CNC, Mechatronics Integration and Custom Machine Design

“Logic will get you from A to B. Imagination will take you everywhere.”

Albert E.

-

12-13-2012, 07:18 PM #3

Registered

Registered

- Join Date

- Oct 2011

- Posts

- 205

The drive led's appear normal, but something is causing them to shut down. Lights look normal when they are on, and when they are off..very strange. Is it possible I have a short in a cable somewhere?

-

12-13-2012, 07:36 PM #4

Do they change when the fault occurs?

When/What process or move they happen in?

Al.CNC, Mechatronics Integration and Custom Machine Design

“Logic will get you from A to B. Imagination will take you everywhere.”

Albert E.

-

12-13-2012, 08:56 PM #5

Registered

Registered

- Join Date

- Oct 2011

- Posts

- 205

Yes they change when the fault occurs, they look the same as they would as if you had hit the e-stop button.

It's happening seemingly randomly when running programs, but I am running near the travel limits in Y minus.

-

12-13-2012, 09:01 PM #6

What is each status of the LED's out of the nine?

Do you have the drive manuals?

Al.CNC, Mechatronics Integration and Custom Machine Design

“Logic will get you from A to B. Imagination will take you everywhere.”

Albert E.

-

12-13-2012, 09:14 PM #7

Registered

Registered

- Join Date

- Oct 2011

- Posts

- 205

with the drives on, Control Volts, Enabled, Drive Ready

with the drives off, Control Volts, Under Volts.

-

12-13-2012, 09:25 PM #8

Registered

Registered

- Join Date

- Oct 2011

- Posts

- 205

no manuals

-

12-13-2012, 09:48 PM #9

http://www.kollmorgen.com/uploadedFi...ds4install.pdf

Under volts could mean either you supply voltage is low, or there is a weak capacitor in the DC supply?

Al.CNC, Mechatronics Integration and Custom Machine Design

“Logic will get you from A to B. Imagination will take you everywhere.”

Albert E.

-

12-13-2012, 10:42 PM #10

Registered

Registered

- Join Date

- Oct 2011

- Posts

- 205

With out going through the link you sent me, I'm quite sure the lights I have showing on the drives are normal for when the drives are on, or not on. The problem is that the drives are turning off when they should not.

-

12-13-2012, 10:58 PM #11

If the drive is indicating the correct LED's but you are receiving a Lost Drive Rdy signal on the input indicated, then if it could either be the contact output on the drive itself or the wiring from that drive output to the input # shown.

If the drives are all the same model, you could try swapping them?

Unless they all have a common enable?

Al.CNC, Mechatronics Integration and Custom Machine Design

“Logic will get you from A to B. Imagination will take you everywhere.”

Albert E.

-

12-14-2012, 02:32 AM #12

tough one when it happens randomly and does not latch the error for you.

Id suggest you download the bds4 manual and read about the faults to see which one(s) can happen on the bds4 and not latch for you to see a red lite afterwards. I dont recall top of my head, but randy would as he repairs these daily. I will pm his phone no and feel free to call him and ask for a walk thru.

-

12-14-2012, 09:55 PM #13

Registered

Registered

- Join Date

- Oct 2011

- Posts

- 205

Ive got a guy at Mag looking into it for me for now.

Looks like it might have something to do with y limit switch, as when this happened i was near the end of the travel in y. I have since moved my setup ahead, and have not had any problems since. Will have to take the covers off and inspect when this job is done.

-

12-15-2012, 02:49 PM #14

very weird.... seems to me the control knows about limit switches and will tell you when one is tripped - not give you a drive off error.... but weirder stuff happens! Keep you eyes peeled....you moved the part machining area and the fault goes away, the control does not give LS error..... sure sounds like it will be back and later identified as a intermittent motor CABLE issue.....might be worth proactively wiggling the crap out of the cables while servos are on and sitting still to see if you can duplicate the error...

-

12-15-2012, 07:09 PM #15

Registered

Registered

- Join Date

- Dec 2012

- Posts

- 0

Just a few things I would check out:

Verify soft limit Parameter.

Hook up meter to limit switch to check response time when you manually engage and disengage.

For troubleshooting purposes you can try swapping out axis drives (if the drives are the same) to see if the error still happens on the Y axis if you think that might still be an issue, but doesn't really sound like one.

One thing I've learned in my many years of troubleshooting equipment... don't always expect your HMI to throw you out an error that is directly involved with the real problem.www.socalpe.com offers CNC retrofit kits, CNC repair services, CNC motion controls, and a variety of CNC Components and accessories.

-

12-15-2012, 10:32 PM #16

Overt promotion of web site

From forum guide lines:

POSTING ADVERTISEMENTS:

This is a forum of ideas, so advertisements are not allowed in this venue. A member may answer another members question about their occupation or business; however, if you are a rep, manufacturer, distributor or retailer for any product you cannot solicit, offer, promote, or market this product in the discussion forums. Offering support or technical answers for the item being discussed is permitted based on the criteria listed above. Please seek out the advertising information CNCzone has available to promote your products.CNC, Mechatronics Integration and Custom Machine Design

“Logic will get you from A to B. Imagination will take you everywhere.”

Albert E.

Similar Threads

-

SOS / help : fanuc 15T system with "OT007 z+ overtravel (Hard) alarm" FORCE sIGNaL

By jlpd in forum FanucReplies: 5Last Post: 10-12-2013, 02:23 AM -

Fanuc spindle drive "not ready"

By Pyretta-Blaze in forum FanucReplies: 2Last Post: 12-11-2012, 12:00 PM -

Are there any third-party DROs (displays) that accept 3-axis "igaging" signal inputs?

By Nelson_2008 in forum Benchtop MachinesReplies: 4Last Post: 10-01-2012, 12:13 PM -

Disable missing "wedge" in lathe simulation?

By Tolyatti in forum GibbsCAMReplies: 3Last Post: 05-24-2012, 07:13 PM -

Acramatic 2100. NC ready signal on PLC output missing

By deepforrest in forum Cincinnati CNCReplies: 2Last Post: 09-23-2010, 07:54 PM

Reply With Quote

Reply With Quote