You'll still have to flip the board over to round the other side of the "tails"... You might want to check out the Leigh Isoloc joints....

As to "classic" dovetails, the problem with machining them on a CNC is handling the sharp corners. While there is a dovetail bit made that will round the tails on the flat, I think it's fine for kitchen cabinetry or commercial stuff, but I'm torn as to whether I would use it for a "craft" piece.

Results 21 to 30 of 30

-

01-03-2013, 10:06 PM #21

Gold Member

Gold Member

- Join Date

- Apr 2009

- Posts

- 5516

-

01-04-2013, 04:57 PM #22

Registered

Registered

- Join Date

- Aug 2011

- Posts

- 999

That is true, but should not be a big deal with a fence jig? Alternatively the pockets could be cut wider so that the tails fit without rounding on the other side and the resulting "defects" be hidden in a blind end.

But for now that is only puzzle solving for me and no specific project.

Edited to say: I just tried it without backside rounding on the CAD and it does not work. Well, it does work but would require milling the other side of the tails anyway so there is no real benefit.

-

01-04-2013, 10:54 PM #23

Gold Member

Gold Member

- Join Date

- Apr 2009

- Posts

- 5516

-

03-17-2013, 06:14 AM #24

Registered

Registered

- Join Date

- Aug 2011

- Posts

- 999

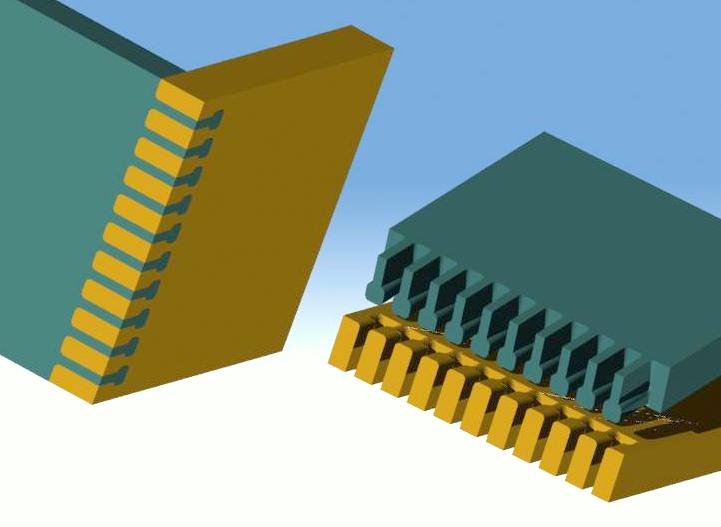

I played a little more with the idea today and believe I found a geometry that works and is extremely simple without leaving voids in the joint. It can be cut with a single 30-degree v-bit (like the Amana In-Groove) and from one side only. I tried to calculate the required angle of the tenons but the vestiges of my trigonometry skills and spatial imagination left me stumped. But with a bit of trial and error I got it together without gaps. The key is that the parts don't join straight but with a 45-degree angle motion.

The wood board needs to be clamped to the CNC at a 15-degree angle to cut the inside of the coves straight but that is easy enough with a pretty shallow wedge shape jig. While my machine does not allow clamping vertical parts, the spindle comes close enough the the edge (about 8 inch) to machine a slightly slanted board.

I think I will try this out the next couple of days.

http://www.youtube.com/watch?v=w-W5ygNEWkc

-

08-04-2015, 04:22 PM #25

Registered

Registered

- Join Date

- Jan 2009

- Posts

- 141

-

08-04-2015, 11:51 PM #26

Registered

Registered

- Join Date

- Aug 2011

- Posts

- 999

Re: Flat Machined Dovetails (related to Gerry's thread)

Box Joint and Dovetail CAM software here: WWW.TAILMAKER.NET

-

08-04-2015, 11:55 PM #27

Registered

Registered

- Join Date

- Jan 2009

- Posts

- 141

-

08-05-2015, 12:03 AM #28

Registered

Registered

- Join Date

- Aug 2011

- Posts

- 999

Re: Flat Machined Dovetails (related to Gerry's thread)

The finger joint software only does 90-degree joints (I do have a beta version that can do acute angles between 22.5 and 90 degrees but it does not work properly yet with larger bits). For the example box I made the lid and bottom puzzle cut with Vcarve and sanded the glued board flat before I started cutting the edge joints. One could develop software to automate the pattern generation for flat joints but I never looked into that because it is quite easy to draw that in CAD. But it might also be a nice Vcarve gadget.

Box Joint and Dovetail CAM software here: WWW.TAILMAKER.NET

-

07-27-2020, 05:51 PM #29

Registered

Registered

- Join Date

- Jan 2008

- Posts

- 4

Re: Flat Machined Dovetails (related to Gerry's thread)

I've been interested in this problem of machining 90 degree joints flat. I haven't found a good solution for dovetail yet, but I figured out a solution for finger joints. I created a design that allows one to CNC finger joints only mounting the stock flat, with no gaps. It does not require two sided machining. It also machines on the inside of the drawer, so you can cut a groove for a the bottom of a drawer at the same time. It uses a combination of straight, roundover and ballnose bits. I'm hoping it will be an efficient way to make a large batch of small drawers for myself. I'm still waiting for my CNC and I'm unable to go back to work and use the CNC there, so for now all I have is the Fusion 360 simulation.

It's a parametric design in Fusion 360 so you can adjust the dimensions, board thickness, number of fingers and it will recalculate automatically. Unfortunately the CAM will not necessarily recalculate, but the design should have all the right contours for the CAM operations.

Short explanation video

https://youtu.be/2piJe4UAKWo

Design file

https://a360.co/3g4L27B

-

08-01-2020, 12:06 AM #30

Registered

Registered

- Join Date

- Jan 2008

- Posts

- 4

Re: Flat Machined Dovetails (related to Gerry's thread)

Correct design file is https://a360.co/2CPozx8

Similar Threads

-

LouieAtienza's "Dovetails on the Flat" Technique, take 1

By louieatienza in forum WoodWorking TopicsReplies: 38Last Post: 07-27-2020, 08:16 PM -

Heya guys. long time. I Need helps please. NONE cnc related but Braai Related

By fransfourie in forum South Africa Club HouseReplies: 0Last Post: 08-26-2013, 05:41 PM -

Reference Flat for Scraping Dovetails

By Ed from NY in forum Uncategorised MetalWorking MachinesReplies: 3Last Post: 08-21-2009, 05:47 AM -

screw thread mounting without machined ends

By Action-KAT in forum Linear and Rotary MotionReplies: 9Last Post: 08-19-2008, 11:57 PM -

Help with a flat thread

By shawn in forum G-Code ProgramingReplies: 8Last Post: 07-15-2005, 06:24 PM

Reply With Quote

Reply With Quote