Hi all,

I recently bought a cheap 40W Chinese laser engraver from eBay. You all know the one I mean. I had low expectations of quality and was pleasantly surprised that the tube was intact. Only a few niggles like the ballast resistor falling off and shorting to the metal case!

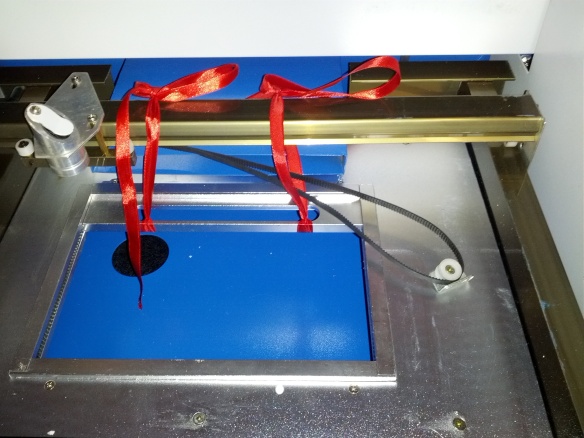

The only problem I have yet to solve is reattaching the belt for the X axis. I came completely unattached and is about 2cm too short to reach the right hand side of the gantry. Looking around the web, there should be some adjustment for belt tension so I don't think it attaches directly to the gantry.

To get the machine working, I've used two long screws to attach it for now, leaving it floating. It seems OK to test the machine but a bit of a kludge. Can anyone with the same laser tell me how it should attach? The seller is as expected pretty useless. I'd rather just fix it myself that go through any more hassle with them.

Thanks in advance.

Results 1 to 6 of 6

-

01-26-2013, 06:04 PM #1

Registered

Registered

- Join Date

- Jan 2012

- Posts

- 53

Help with machanics of Chinese DC-K40 machine

-

01-27-2013, 11:55 AM #2

Registered

Registered

- Join Date

- Nov 2008

- Posts

- 382

hi fred

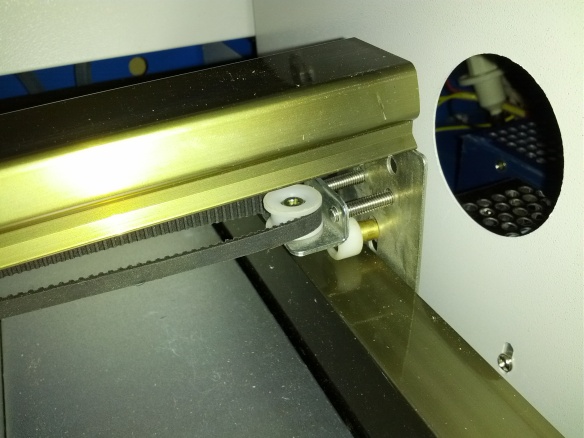

this pulley goes on the right side of the gantry on the vertical inside the chanel . you got there two holes under the top screws there the pulley needs to be attached. usually there is a big hole in the seperation wall what I dont see in your case or is there?

it is quite a bit of fiddeling but watch out that your screws are not to long or they would block the belt.

if you need more help just email me private to [email protected]

greetings

walt

-

01-28-2013, 02:40 PM #3

Registered

Registered

- Join Date

- Jan 2012

- Posts

- 53

Walt,

Thanks. There is a hole for adjustment - just not in shot. I found two long screws and attached the belt. It looks like a bit of a bodge to me, but I wouldn't be too surprised to find that this is how it's actually done in the factory! Is this how yours looks?

I've sent the photo to the eBay seller but they seem to be after the path of least effort and I'm sure they'll tell me it's fine like that.

Fred

-

01-28-2013, 02:53 PM #4

Registered

Registered

- Join Date

- Oct 2007

- Posts

- 385

That is exactly the way mine is. Now just reattach the extrusion to the bracket and make sure the belt is the right tension. Not too tight, but not too loose either.

Milt

-

01-28-2013, 02:58 PM #5

Registered

Registered

- Join Date

- Jan 2012

- Posts

- 53

Good news! The extrusion is of course attached. I just moved it for the photo. I tensioned the belt to match the Y axis belts. I'll probably add a drop of thread lock to ensure it doesn't come loose.

-

01-30-2013, 11:22 AM #6

Registered

Registered

- Join Date

- Nov 2008

- Posts

- 382

Hi fred

just make sure the screws are not to long because then they will grind the belt and damage them and finally just snap.

Oh I just did see yourroler from the Y axis it looks like its to loos. it needs to be tight to the rail there should be no movement

if you try to lift the gantry up if it is you need to loosen the screw from the side hole, push down the roler and re tighten the screw

greetings

walt

Similar Threads

-

Looking for Chinese Machine w Mach3

By restos in forum Chinese MachinesReplies: 6Last Post: 10-31-2011, 03:58 AM -

Workflow w/chinese machine & DSP

By jensenium in forum Chinese MachinesReplies: 3Last Post: 11-01-2010, 10:14 PM -

Which chinese laser machine?

By skalaa in forum Laser Engraving / Cutting Machine General TopicsReplies: 13Last Post: 07-23-2010, 04:24 PM -

Chinese laser machine

By Supo Oluwasakin in forum Want To Buy...Need help!Replies: 5Last Post: 03-31-2010, 10:01 PM -

Looking for CNC Chinese machine

By cup67 in forum Chinese MachinesReplies: 0Last Post: 05-10-2008, 08:28 PM

Reply With Quote

Reply With Quote