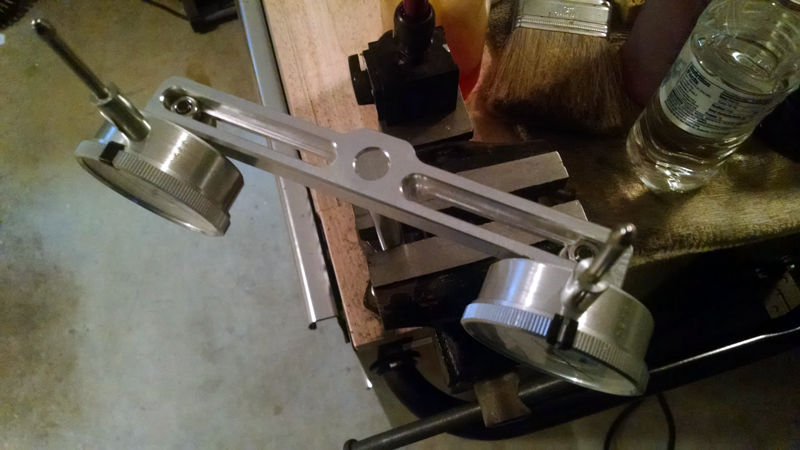

I built a tramming tool out of some simple 1 inch aluminum angle and a couple dial indicators to work through the last of the geometry issues on the mill. The indicators were set at a fixed distance which seem to always fall either on the table surface or in the slot but never on both. I decided to fix this problem by building a better device. I like the Pro Tram devices but again the problem is they are fixed either at 5 inches or 3 inches. I wanted to be able to adjust to any distance. Mine will go from 2.5 inches out to 7 inches center to center on the dial indicators.

This is the best work to come off the mill so far. Chamfers are finally consistent around the part. Holes come out in the correct spots and round features are almost round to within .001. I have some vibration that is creating ripples in the surface finish on side cuts but this is probably about as good as I'll bother making this machine as the plans are already being drawn up for a new shop behind that house that will include a new machine purchase. Something a little larger and all linear rail is the goal.

Thread: Well the first part is made....

Results 21 to 40 of 41

-

12-12-2015, 01:52 AM #21

Neuer Benutzer

Neuer Benutzer

- Join Date

- Jan 2013

- Posts

- 630

Re: Well the first part is made....

-

12-12-2015, 01:32 PM #22

Registered

Registered

- Join Date

- Dec 2015

- Posts

- 29

Re: Well the first part is made....

Nice work,

What Cad program are you using?

-

12-12-2015, 03:26 PM #23

Neuer Benutzer

Neuer Benutzer

- Join Date

- Jan 2013

- Posts

- 630

Re: Well the first part is made....

I'm doing everything in Fusion 360.

-

12-12-2015, 11:07 PM #24

Registered

Registered

- Join Date

- Mar 2015

- Posts

- 178

Re: Well the first part is made....

Great work Kenny

I used Inventor many years ago. Is fusion 360 a new version of Inventor?

-

12-13-2015, 04:57 PM #25

Neuer Benutzer

Neuer Benutzer

- Join Date

- Jan 2013

- Posts

- 630

Re: Well the first part is made....

I'm not sure of the lineage of the Fusion product. I just started using Fusion 360 due to it's extremely economical access to hobbyist. Previously the only exposure to I had to Cad was a 2006 version of Solidworks.

-

10-21-2017, 05:22 AM #26

Neuer Benutzer

Neuer Benutzer

- Join Date

- Jan 2013

- Posts

- 630

Re: Well the first part is made....

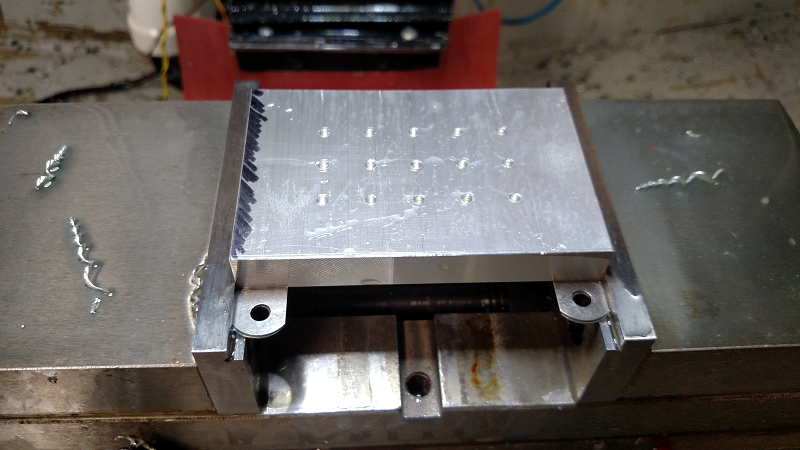

Still learning....still occasionally having problems. Still a lot of fun when you get it right. Tonight's project was my first attempt at using saw jaws on the new double vise. It actually went well and is another tool to add to the skillset.

I had a couple machine stalls in the first couple of attempts that came down to a gib screw that had backed off and let the gib jam.

Attachment 375978

Soft Jaws and a good first op part.

Attachment 375980

And a successful second OP.

Attachment 375982

A couple threaded holes and a couple slots to do tomorrow and these will be finished.

-

10-22-2017, 12:02 AM #27

Neuer Benutzer

Neuer Benutzer

- Join Date

- Jan 2013

- Posts

- 630

Re: Well the first part is made....

Closer...

Attachment 376024

Need to grab the correct washers and some nyloc nuts but it's on the bike.

Attachment 376026

-

10-25-2017, 06:09 PM #28

Member

Member

- Join Date

- Dec 2015

- Posts

- 923

Re: Well the first part is made....

Nice reservoir mount!

-

10-25-2017, 06:34 PM #29

Neuer Benutzer

Neuer Benutzer

- Join Date

- Jan 2013

- Posts

- 630

Re: Well the first part is made....

Probably overkill but it gets it out of the tail section. Paving the way for a monocoque piece to be made.

-

10-25-2017, 09:39 PM #30

Member

Member

- Join Date

- Oct 2013

- Posts

- 543

Re: Well the first part is made....

Kenny,

Very cool, nice work. Must be neat to draw something and have the machine make it. I'll be there soon, I hope!

Stuart"THE GRIZZ" photo album - https://goo.gl/photos/yLLp61jooprtYzFK7

Youtube - https://www.youtube.com/channel/UCT2lq9obzEnlEu-M56ZzT_A

-

10-25-2017, 09:48 PM #31

Neuer Benutzer

Neuer Benutzer

- Join Date

- Jan 2013

- Posts

- 630

-

10-26-2017, 03:11 PM #32

Member

Member

- Join Date

- Dec 2015

- Posts

- 923

Re: Well the first part is made....

I was never much a fan of remote reservoirs, but they do offer nice packaging benefits. What kind of monocoque tail? Aluminum stressed panel or composite?

-

10-26-2017, 04:01 PM #33

Neuer Benutzer

Neuer Benutzer

- Join Date

- Jan 2013

- Posts

- 630

-

10-27-2017, 02:41 PM #34

Member

Member

- Join Date

- Dec 2015

- Posts

- 923

Re: Well the first part is made....

Sounds like fun, albeit dusty, project. I've been looking into print heads for my G0704 so I can print molds for various composite projects I have. Unfortunately the G0704, as you know, doesn't have the space for large parts so they'd have be sectional. Similarly, this is for a motorcycle project of my own.

-

10-27-2017, 03:07 PM #35

Gold Member

Gold Member

- Join Date

- Nov 2009

- Posts

- 4415

-

10-27-2017, 03:38 PM #36

Member

Member

- Join Date

- Dec 2015

- Posts

- 923

Re: Well the first part is made....

Yeah, I've been torn about it for a while, but here's the way I see it. I have an open A-axis already (though that's changing soon, but I'll probably expand my BOB/drivers) and decent print heads can be had for around $100 these days. To buy a 3d printer that has the same work envelope as the g0704 is going to be a good bit more expensive than the price of the print head. Considering that there is only a few projects initially that I have for printing I think a print head would pay itself off before a dedicated printer. For example, I purchased a small laser cutter, I used it to reproduce a specific wiper seal (for a vintage motorcycle damper) that is not available to buy, I now have 70 or more wiper seals sitting on a shelf and the laser cutter is used as a desk for my keyboard, mouse, and measuring tools at the G0704 controller. I feel a dedicated 3d printer would end up with the same fate. Of course, the bigger issue is that I am fairly space limited in my 500 square foot garage, adding more junk is almost certainly not desirable, and the wife would divorce me if I put it in the house.

All of that said, I'm willing to hear your side of the story.

-

10-28-2017, 02:54 PM #37

Gold Member

Gold Member

- Join Date

- Nov 2009

- Posts

- 4415

Re: Well the first part is made....

It will definitely work and being that most here are here to create, I say do it. As a part time printer it will be fine. Your arguments were the same as mine. I had the 4 axis controller and an A2ZCNC mill, etc. It was fun just futile. Kind of like converting a manual Chinese machine into a CNC machine ;-)

Here is a link to the printer head in action.

https://youtu.be/1XqlivRhLCcA lazy man does it twice.

-

11-01-2017, 09:20 AM #38

Registered

Registered

- Join Date

- Jul 2004

- Posts

- 108

Re: Well the first part is made....

Ha, Kenny, fancy I run into you here

Nice work! Will follow this closely!

Cheers,

Beano

-

03-03-2018, 02:57 AM #39

Neuer Benutzer

Neuer Benutzer

- Join Date

- Jan 2013

- Posts

- 630

Re: Well the first part is made....

Beano...the world is small. Sim Racing and now CNC. The man with the giant servo motor.

I ran my first part today that included some 3d profiling. Turned out ok. Not mold quality by any means but the machine did what it was supposed to do. Can't wait to get the new house built so I can have space for a better piece of hardware. The little BF20 does ok but I just want more accuracy already.

-

04-01-2018, 03:14 PM #40

Neuer Benutzer

Neuer Benutzer

- Join Date

- Jan 2013

- Posts

- 630

Re: Well the first part is made....

She's still making parts and I'm still learning something new every time I do something different. Some one needed some pedal faces for a new set of sim racing pedals he is building.

Similar Threads

-

Need CNC part made RFQ

By neastman in forum North America RFQ'sReplies: 6Last Post: 09-04-2012, 09:52 PM -

first little part made

By mike2768 in forum Canadian Club HouseReplies: 2Last Post: 12-31-2008, 12:33 AM -

RC car part made with our SX3

By metalworkz in forum Syil ProductsReplies: 7Last Post: 07-21-2008, 07:13 PM -

just made my first part

By honda in forum Benchtop MachinesReplies: 2Last Post: 05-01-2008, 10:51 PM -

RFQ- need a part made

By cnc2k in forum Employment OpportunityReplies: 6Last Post: 04-27-2005, 08:40 PM

Reply With Quote

Reply With Quote