Started this build about a week and a half ago. This is my first CNC machine. I have some hands-on experience with a 2.5D plotter, and some working knowledge of waterjet.

Stand build commences.

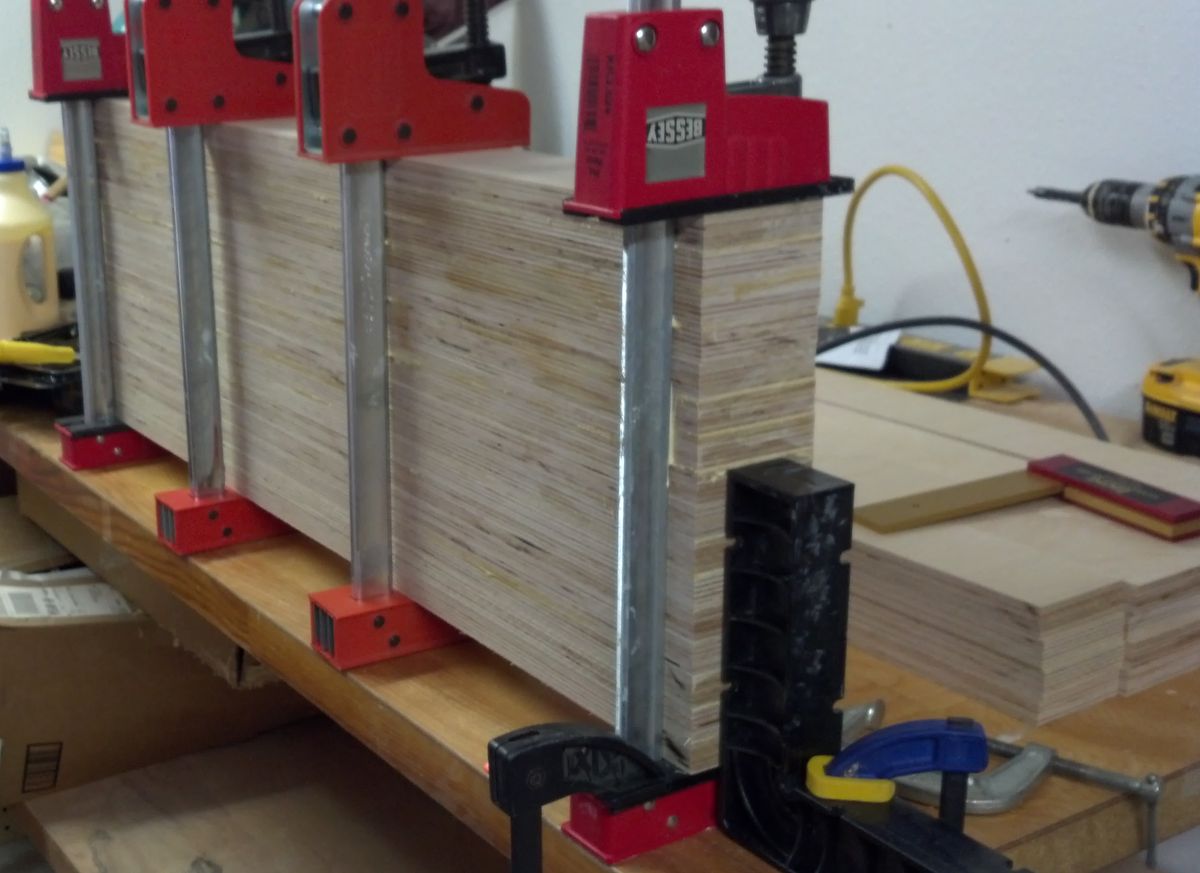

Laminating the baltic birch for the legs.

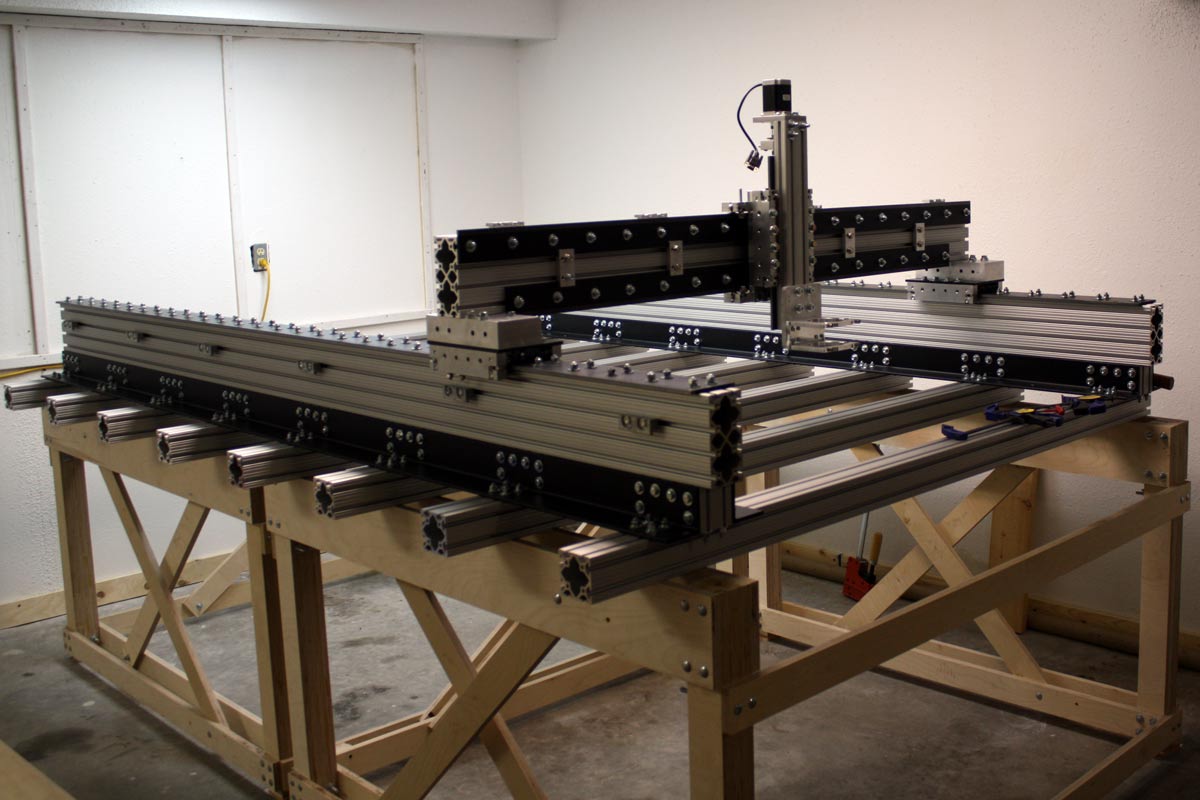

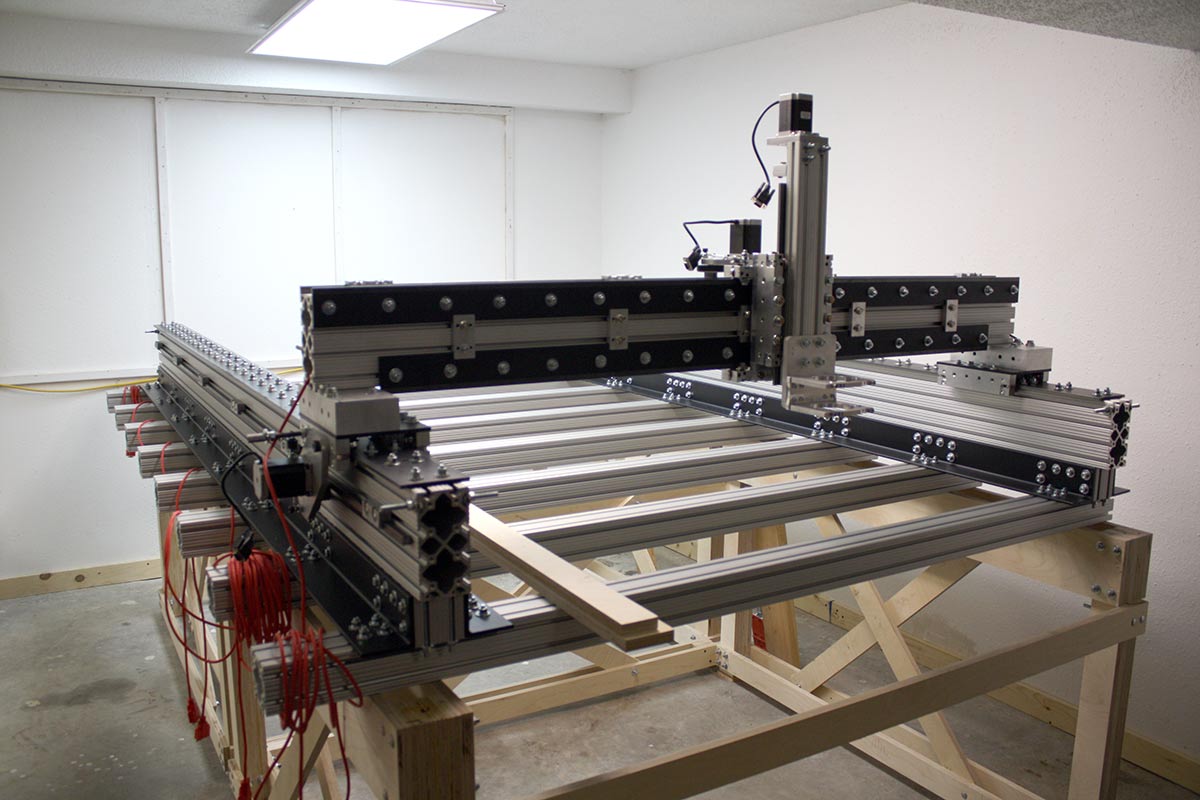

Starting to see how much of my garage will be consumed by this.

TSC loot.

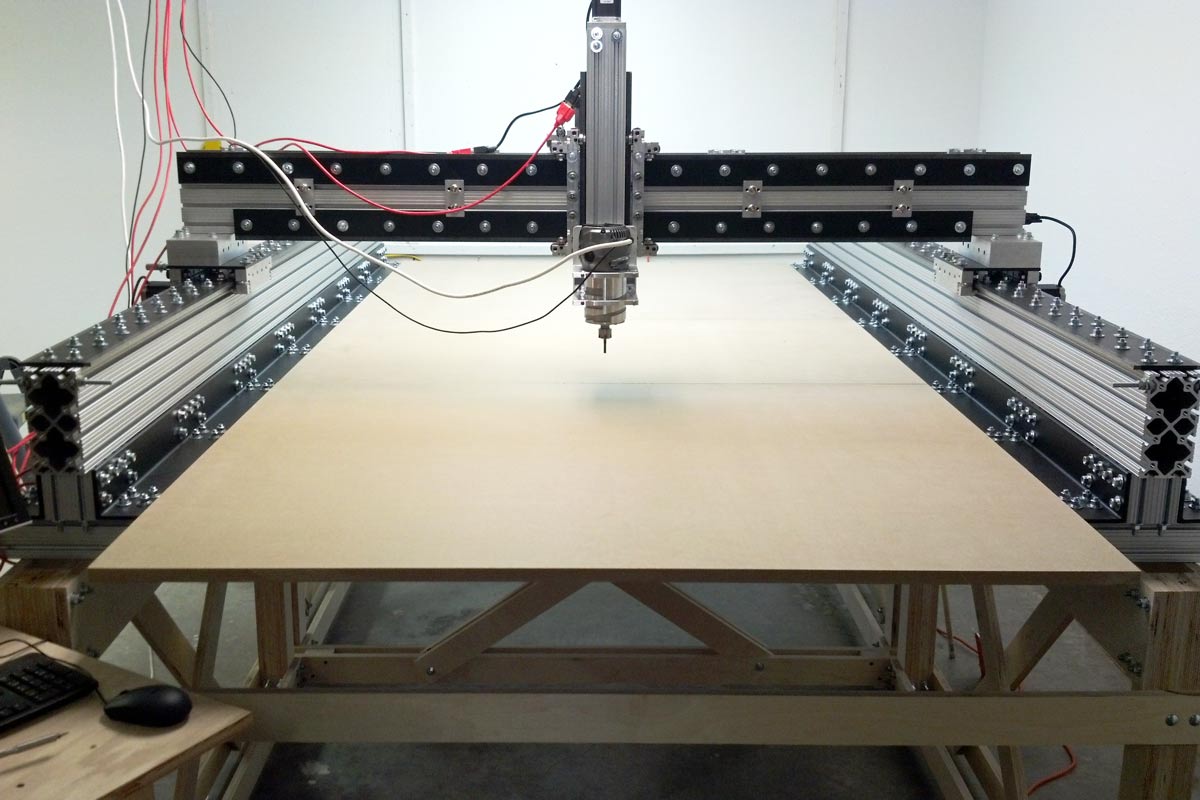

Stand completed.

3x3x1/4x111" steel angle.

8020 arrived in good shape.

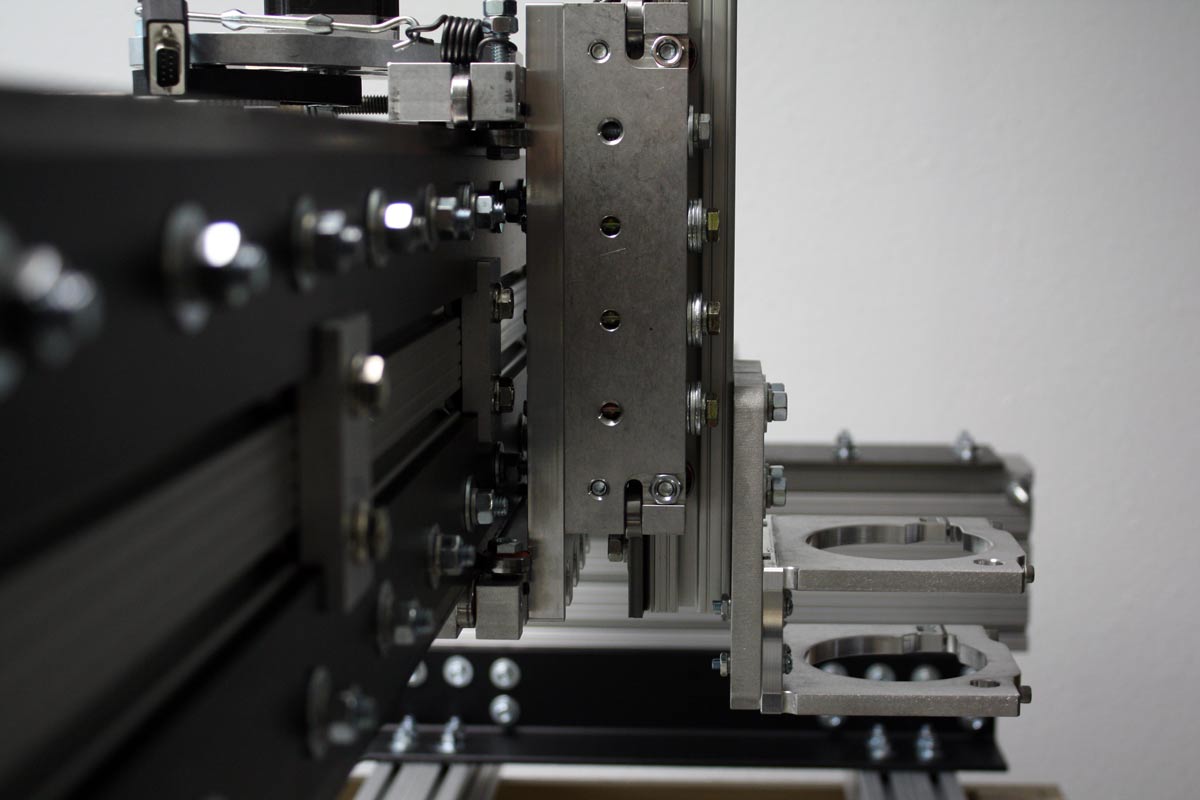

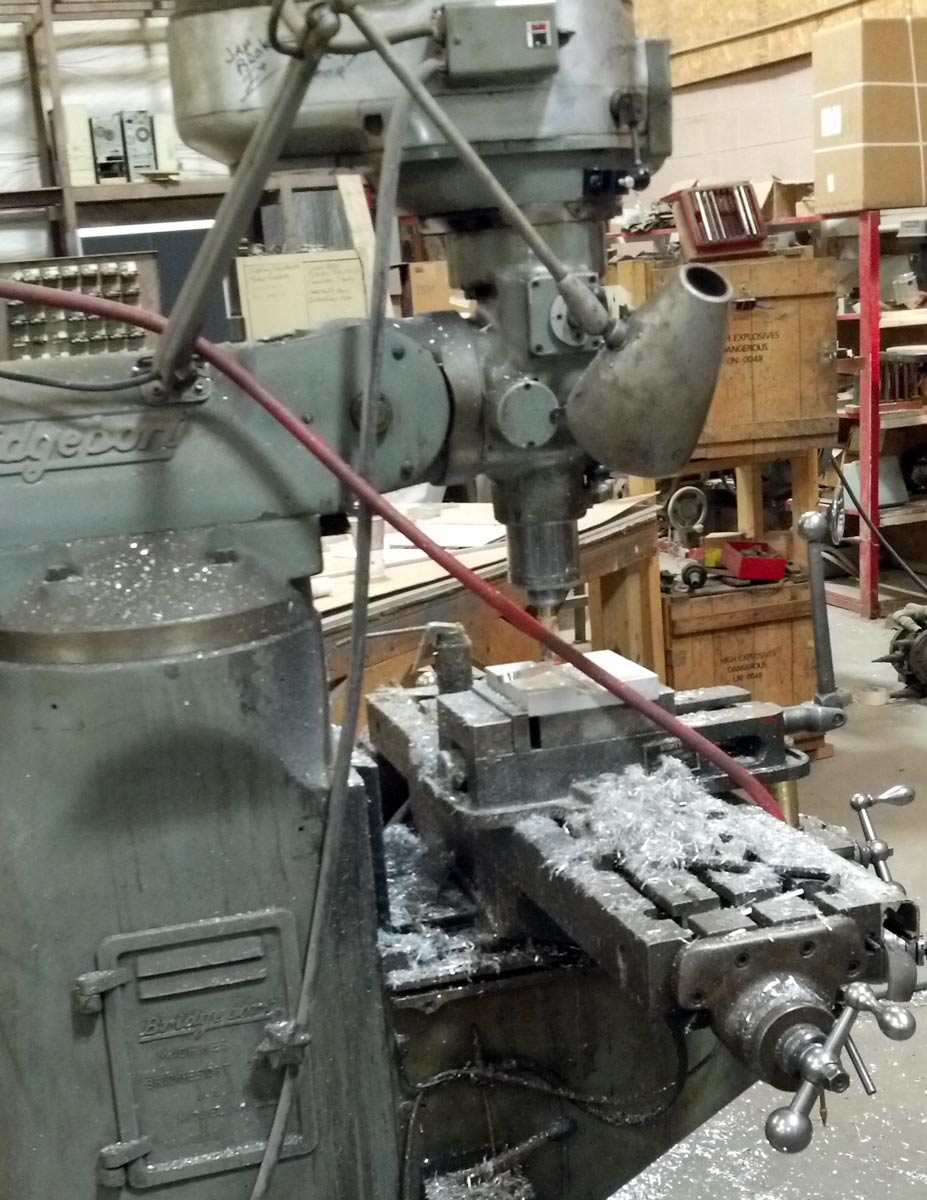

I am fortunate to have access to a machine shop. This mill made relatively quick work of the holes in the angle and 8020. Still many hours - but after first trying with my drill press and no elegant means of material handling, this was a huge improvement. Digital readout was handy, though we relied on the marked holes for the angle.

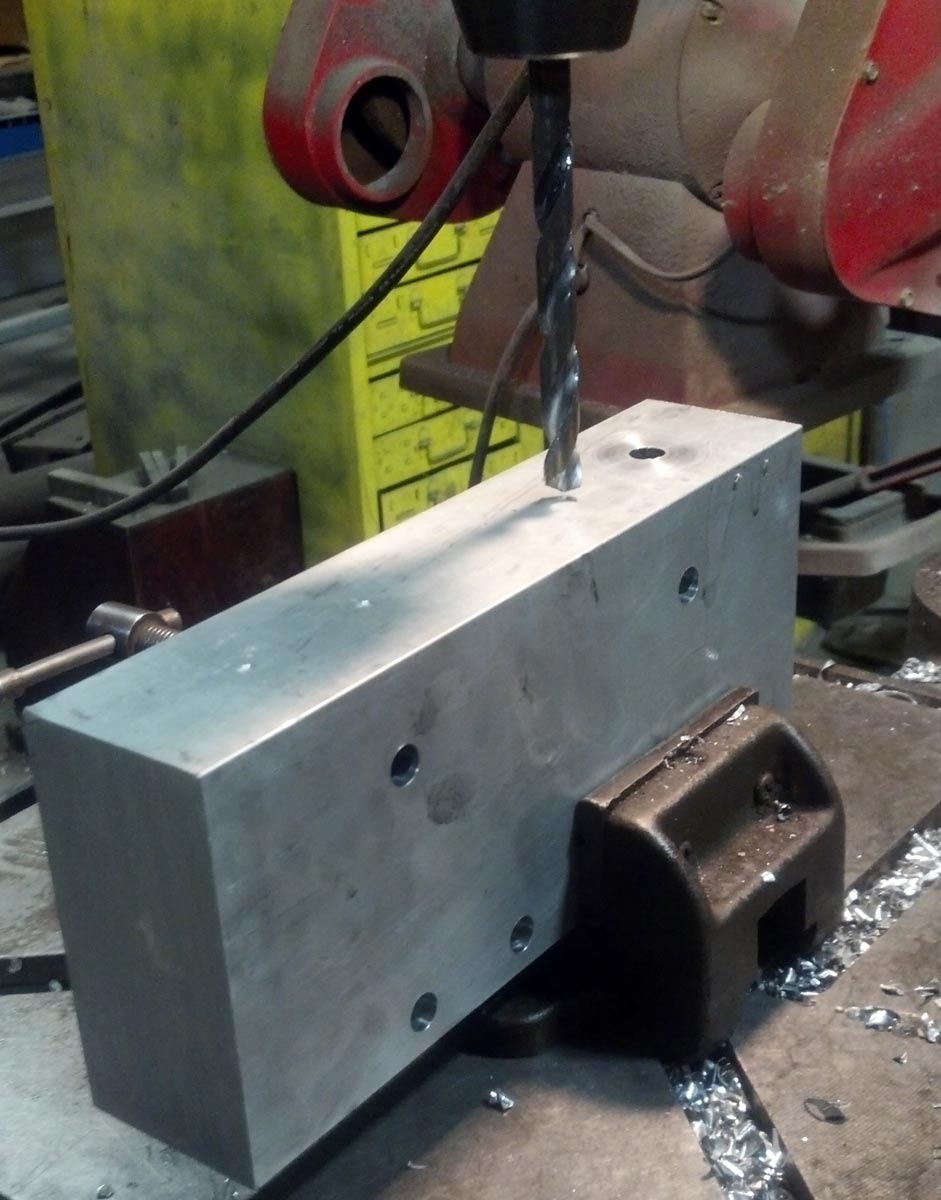

Plain drill press for the solid aluminum.

320 holes in the angle, 116 in the aluminum.

I'm waiting on a bunch of steel parts from a laser-cutting outfit. Next step is powder coating, then assembly begins.

Thread: KRMx02 50x102 Build

Results 1 to 20 of 20

-

05-03-2013, 05:34 PM #1

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 16

KRMx02 50x102 Build

-

05-06-2013, 02:47 PM #2

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 16

Stand is leveled now. That was easier said than done.

-

05-13-2013, 04:56 PM #3

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 16

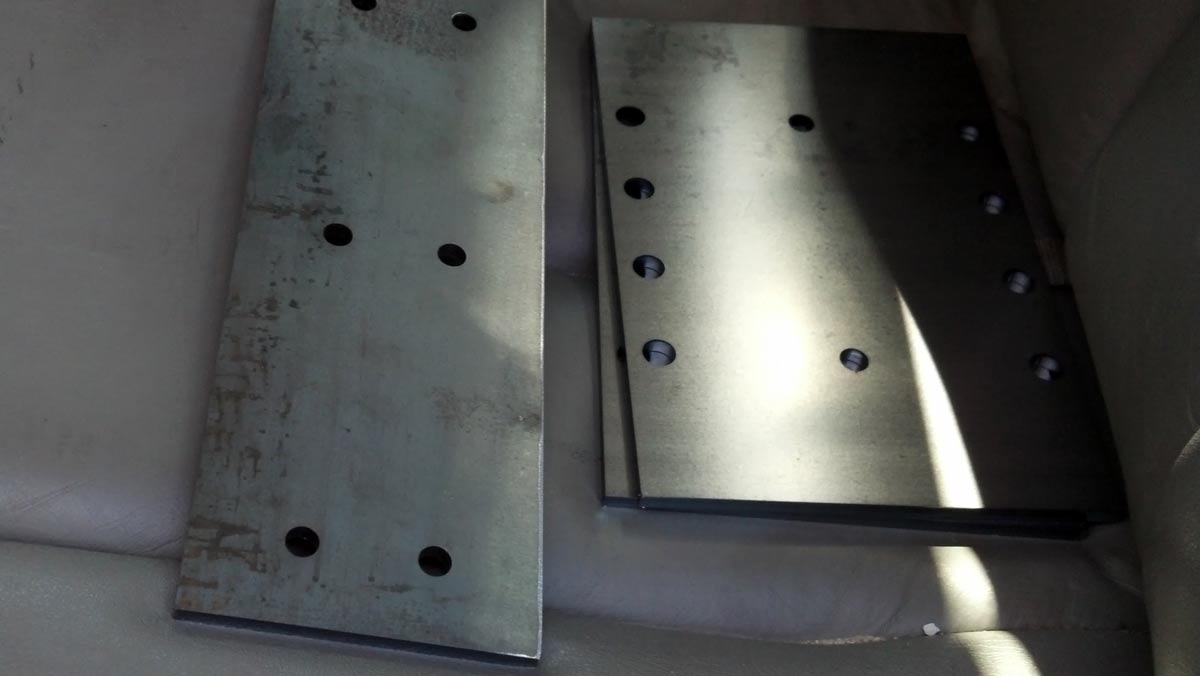

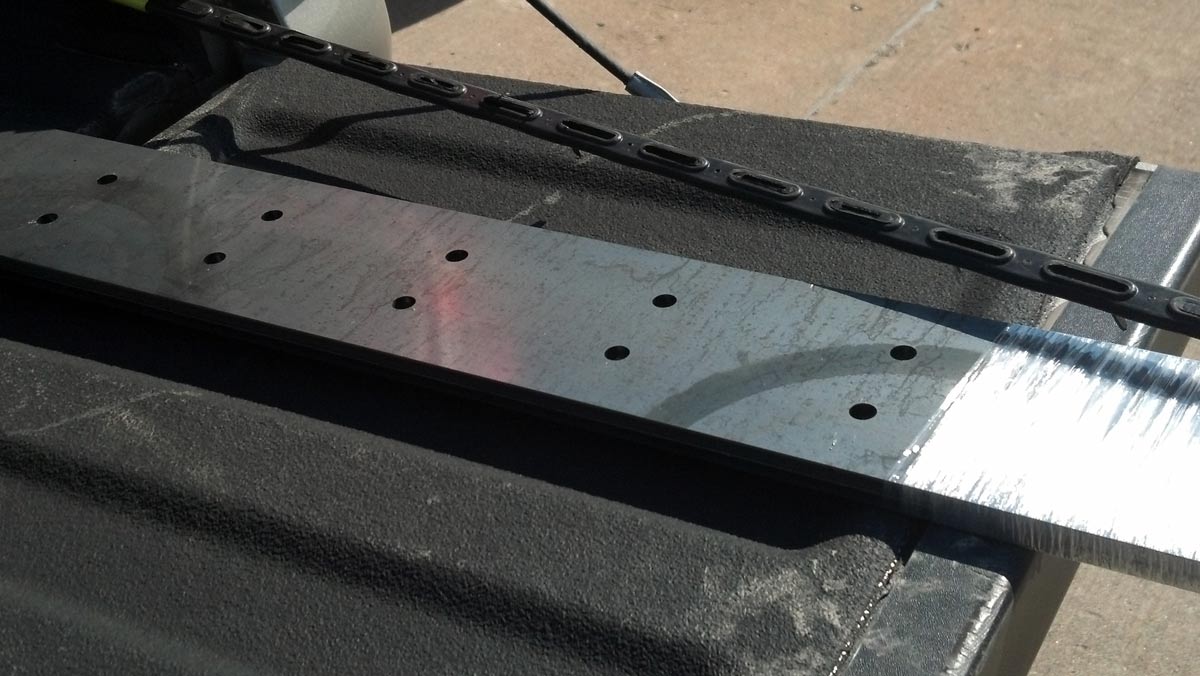

Waiting on the angle pieces to be powder coated so I can start the assembly. Picked up the rest of my steel parts this morning, also to be coated.

-

05-13-2013, 07:47 PM #4

Registered

Registered

- Join Date

- Mar 2013

- Posts

- 12

I'll be watching your build progress.

-

05-19-2013, 12:23 PM #5

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 14

Nicely written, thanks for the pictures, I am looking forward to your next post ;-)

-

05-19-2013, 01:46 PM #6

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 16

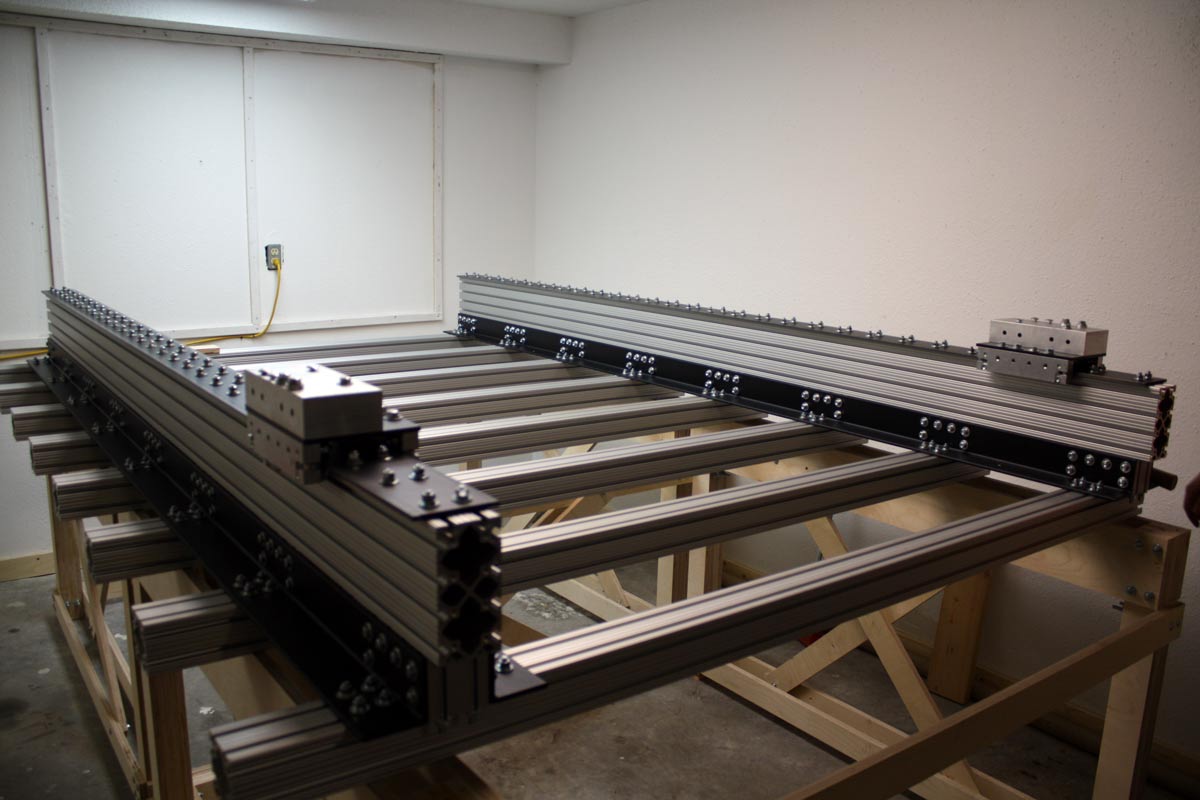

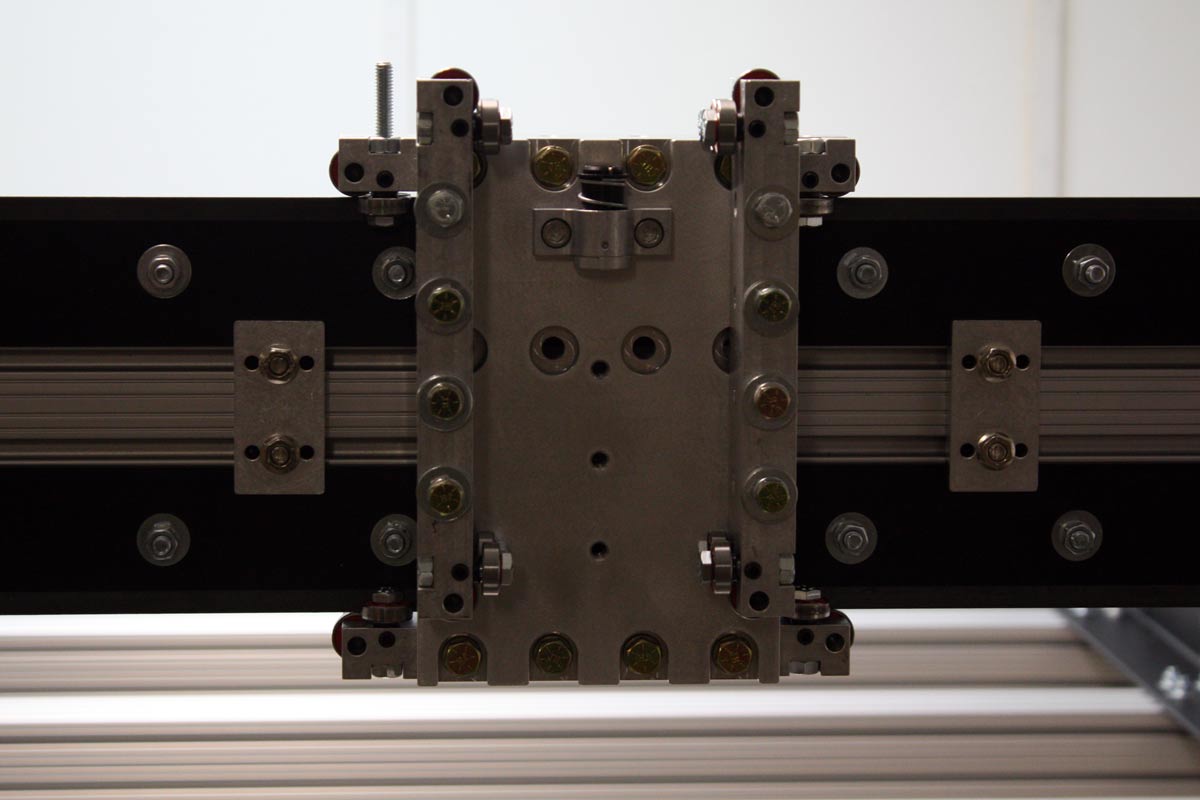

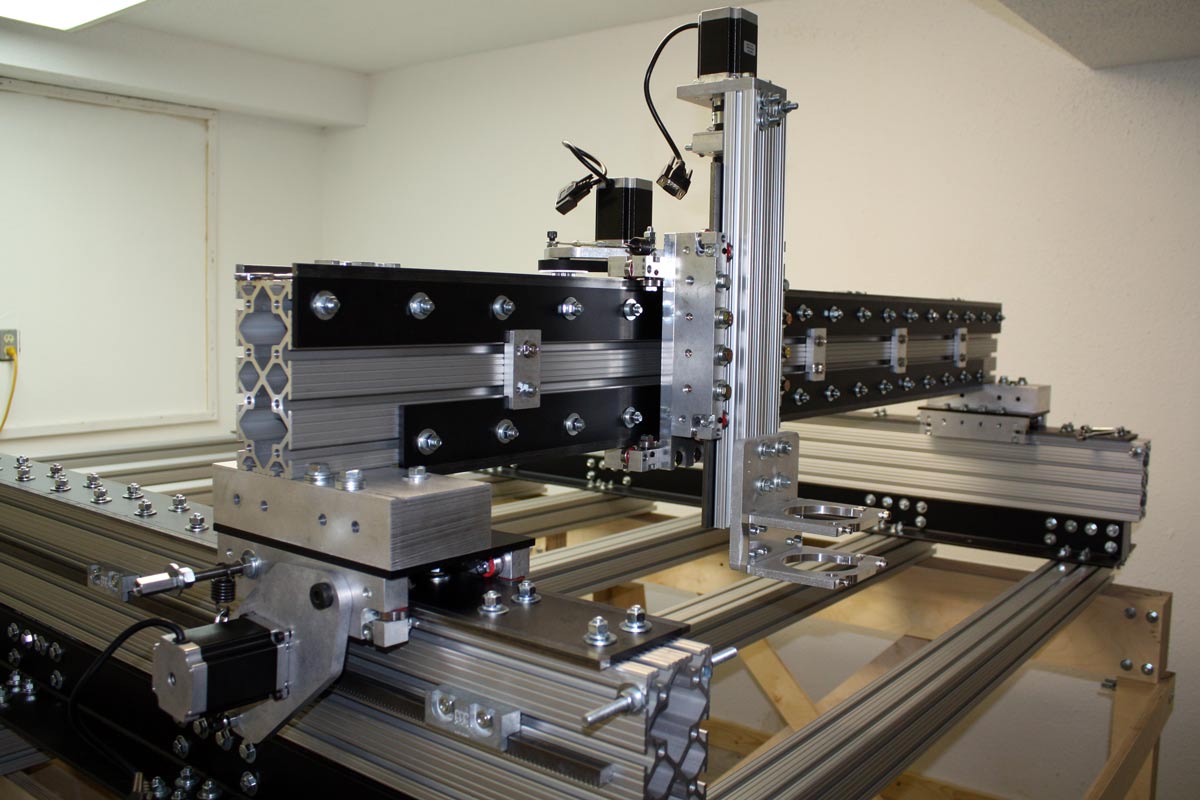

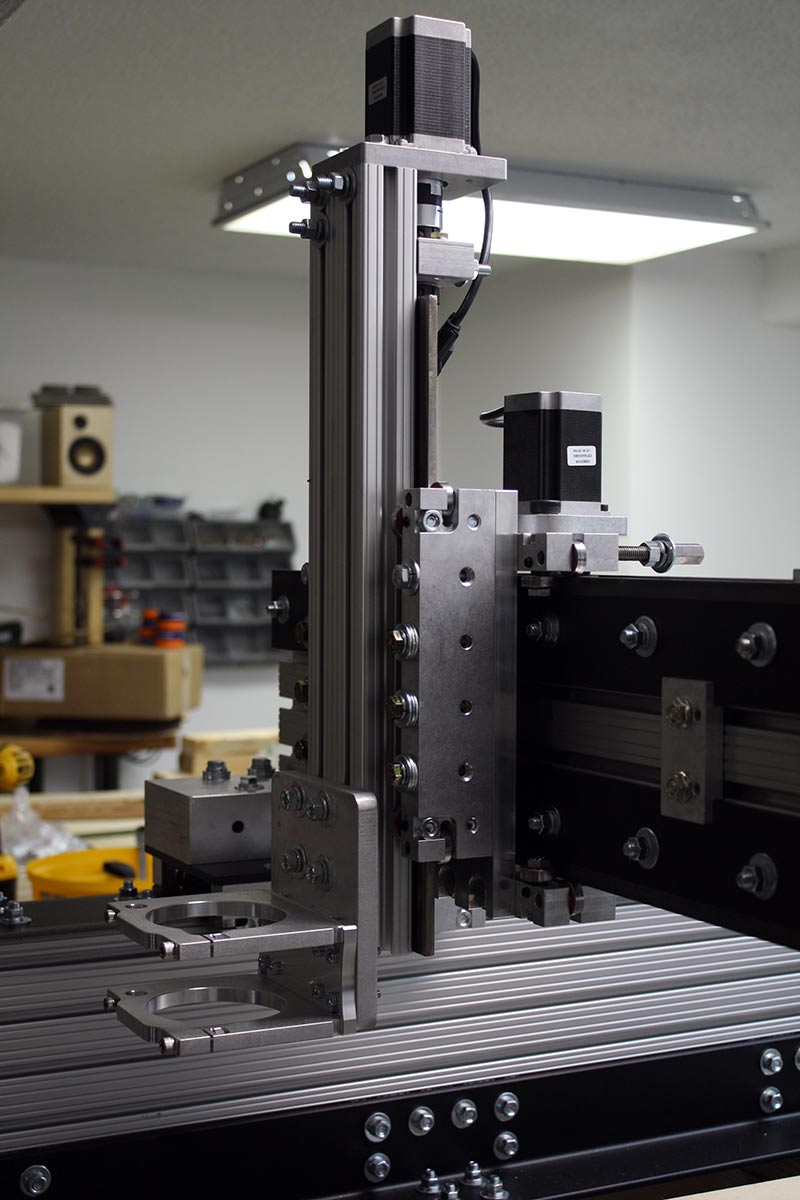

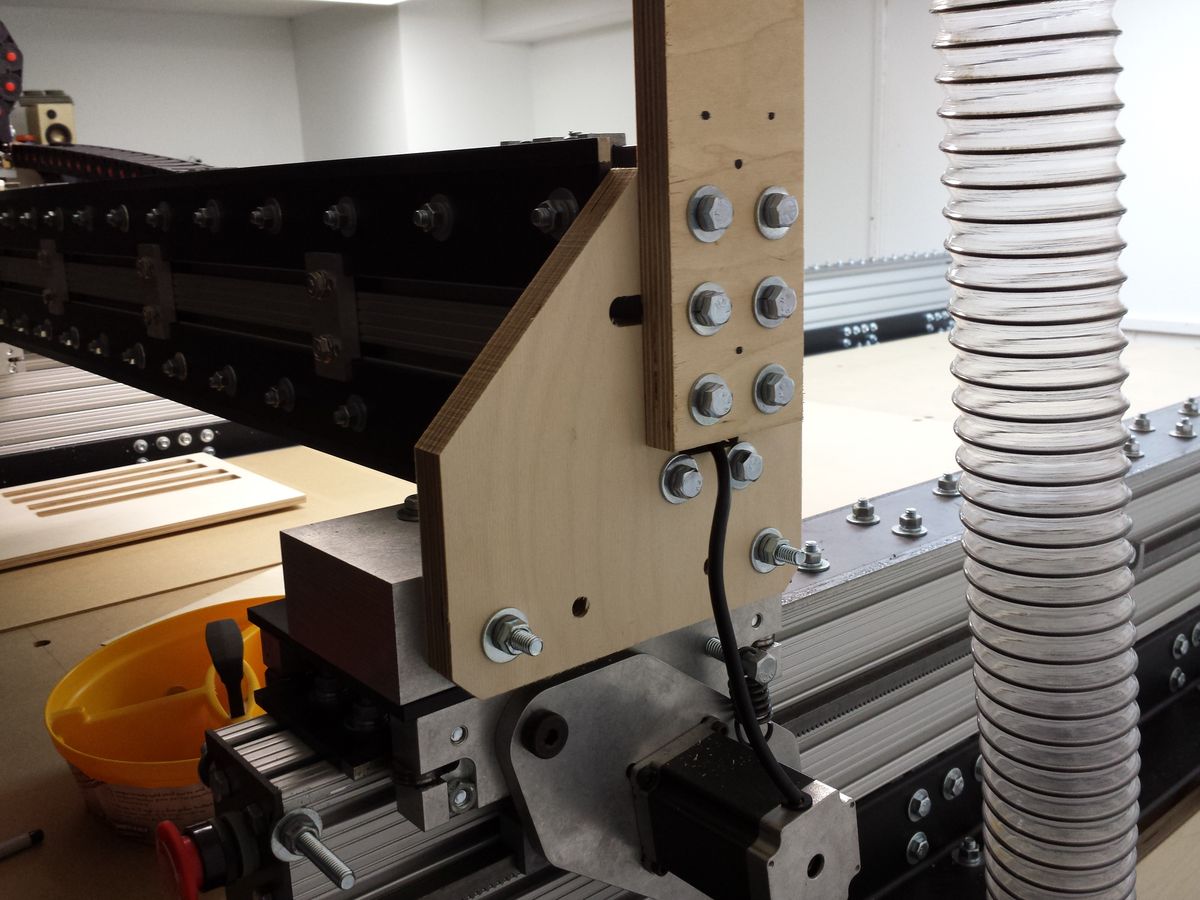

Really getting somewhere now. Yesterday felt like the real day 1.

Started stalking the powder coater at 9am. The second of two batches was out of the oven at 3:30. We ran out of lock washers and a few needed bolts around 10 PM. As soon as TSC opens, we will resume assembling the Y-Carriages.

-

05-20-2013, 03:33 AM #7

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 16

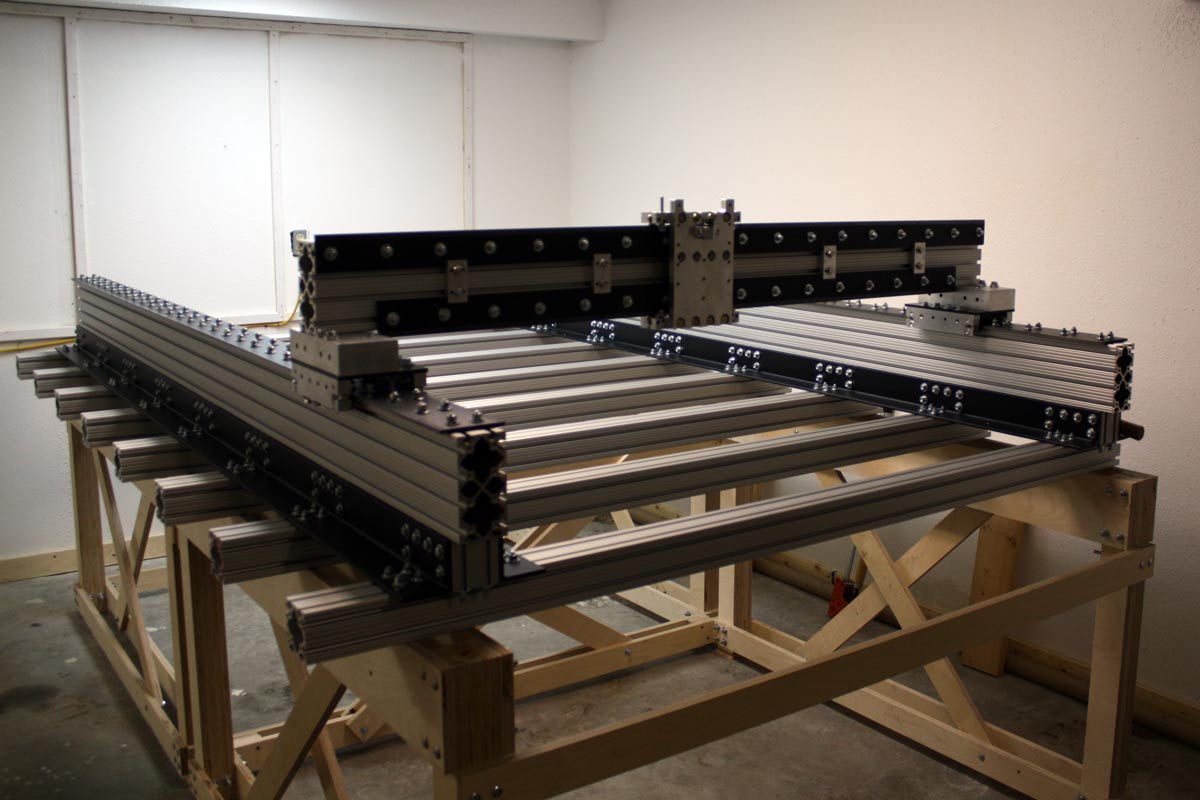

Day 2 (sort of). Complete through chapter 8. Next step: Electronics.

Hit a little hitch when we were testing the right carriage assembly. After a little head scratching, we discovered that the right Y-rail had a subtle bow in it. When the carriage reached the center, the heads of the nuts securing the right-side vertical bearings would begin to dig into the aluminum extrusion.

After some panic and depression at the thought of starting over with a fresh rail, we tried to bend it out. It was actually much easier than expected. Two clamps, a 2x6, and 15 minutes later there was relief. After that it was pretty much smooth sailing.

-

05-20-2013, 11:57 AM #8

Registered

Registered

- Join Date

- Nov 2004

- Posts

- 89

Baniels

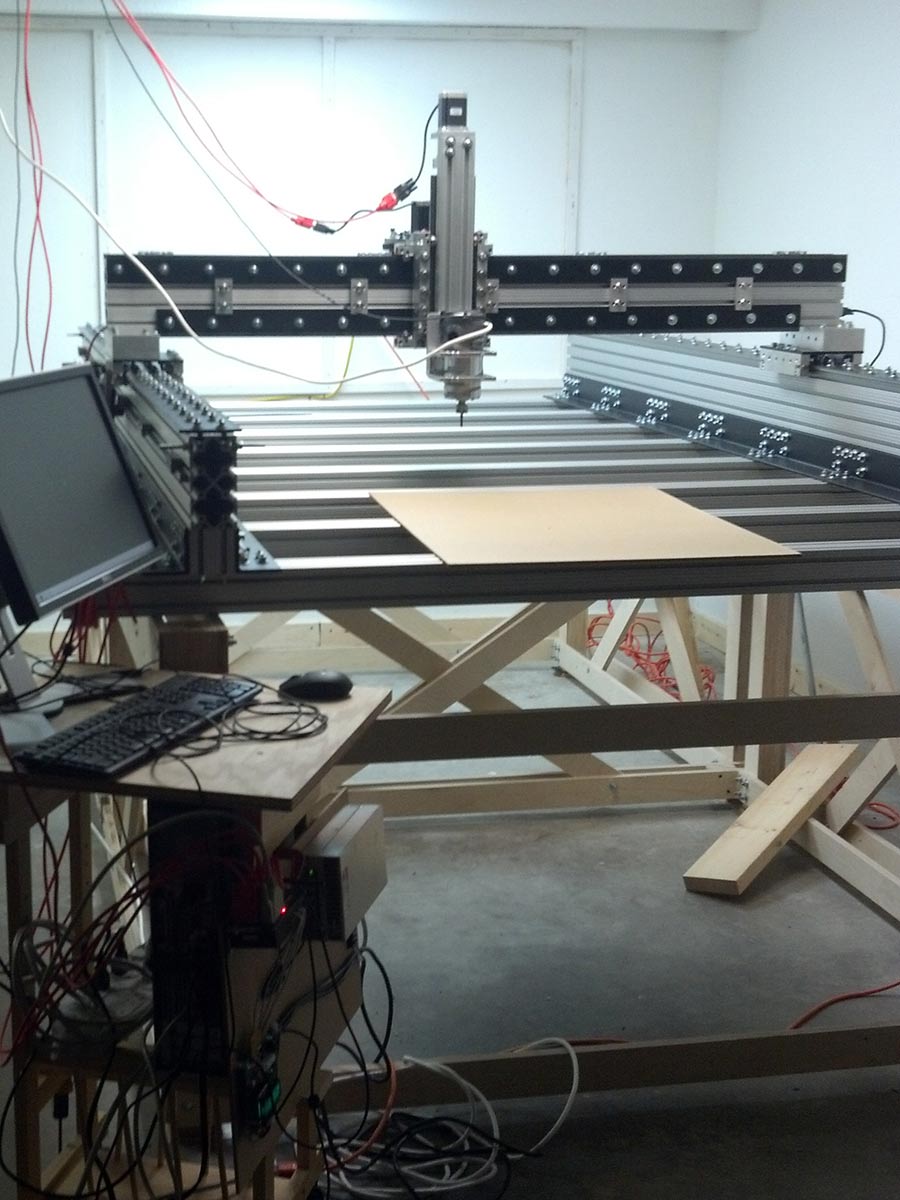

This has to be the stoutest router build I've seen. Why the wood base?

Ed

-

05-20-2013, 01:02 PM #9

Registered

Registered

- Join Date

- Mar 2012

- Posts

- 276

Holy bolts!

My CNC Router Build - http://tinyurl.com/c3vs3ca

-

05-20-2013, 03:00 PM #10

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 16

This was recommended by Michael from Kronos - he says it can help dampen vibrations. It was cheap and easy to build. It shows no signs of not being up to the task. It is quite stout itself. Link.

You aren't kidding!

-

05-22-2013, 04:16 PM #11

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 16

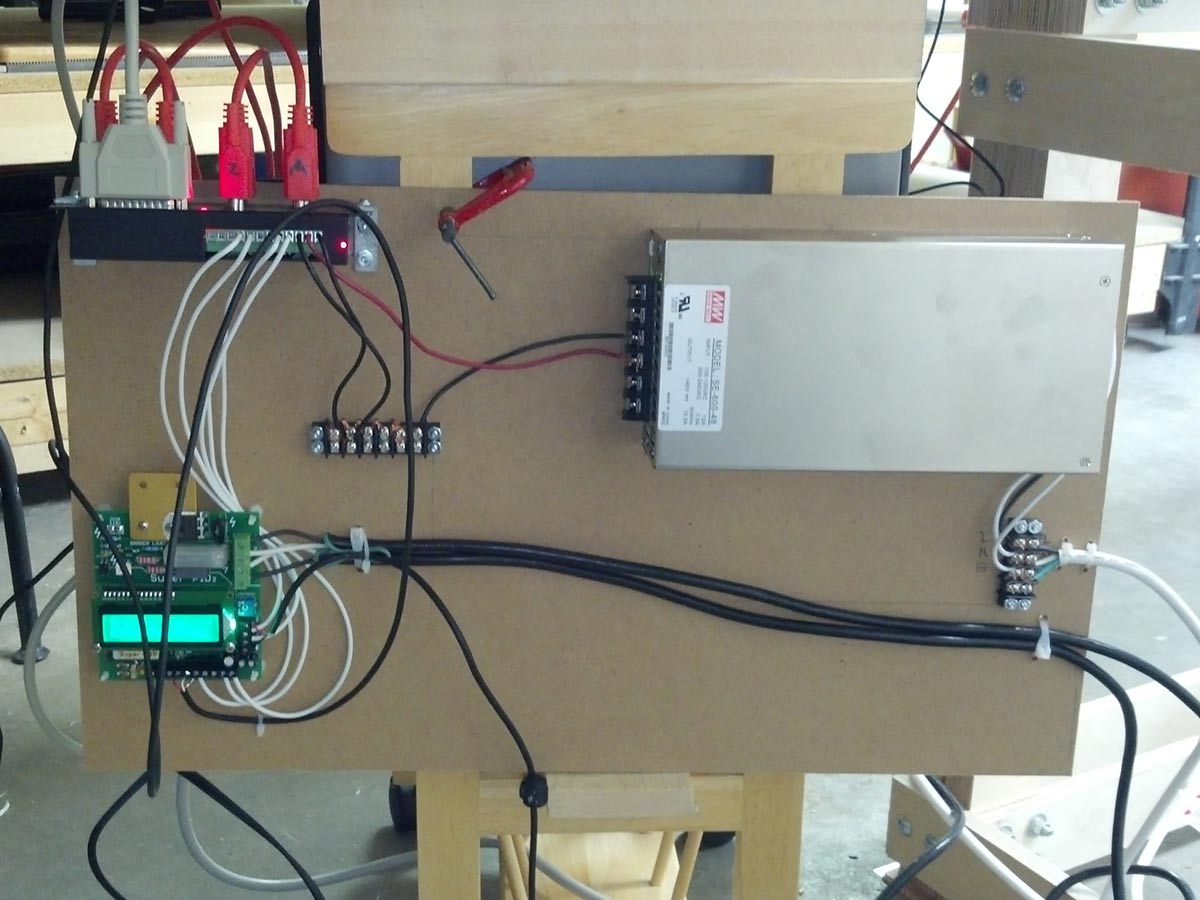

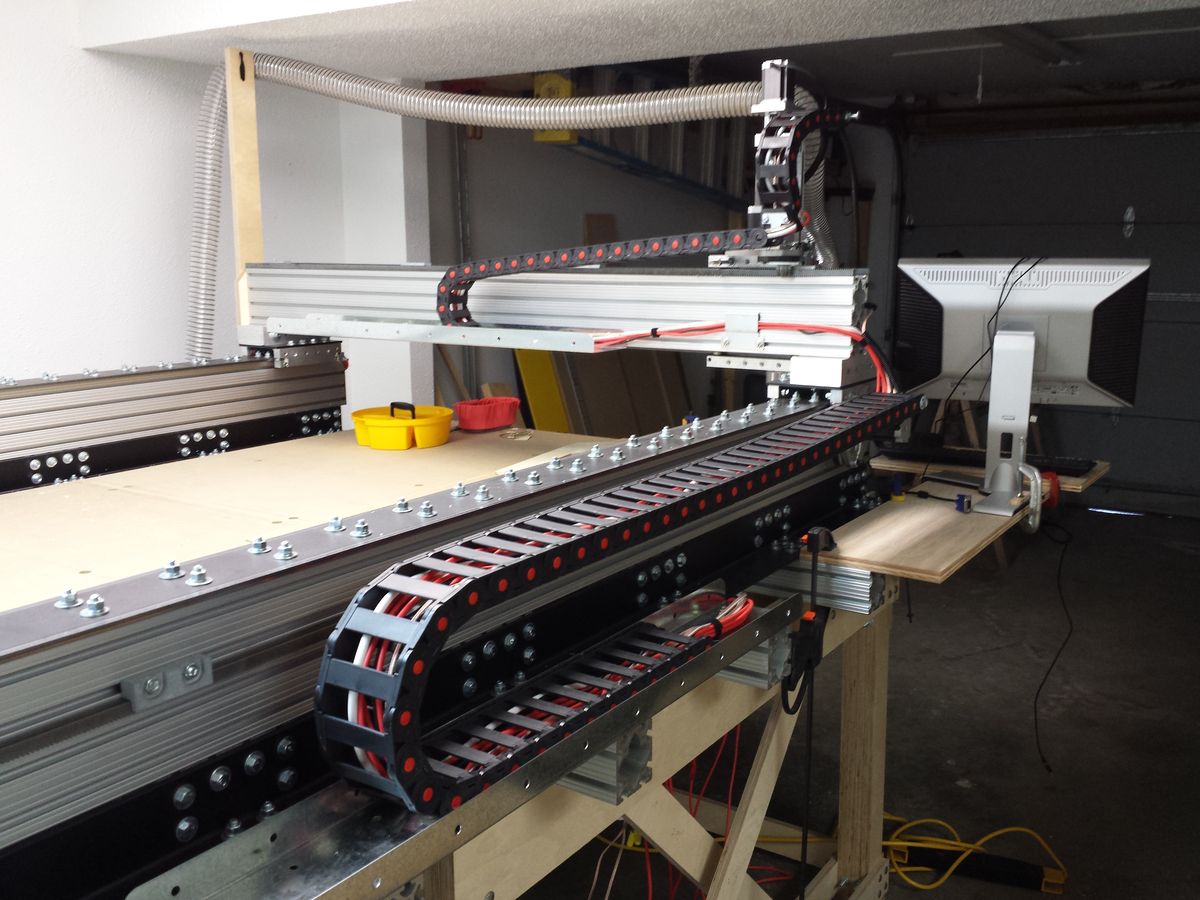

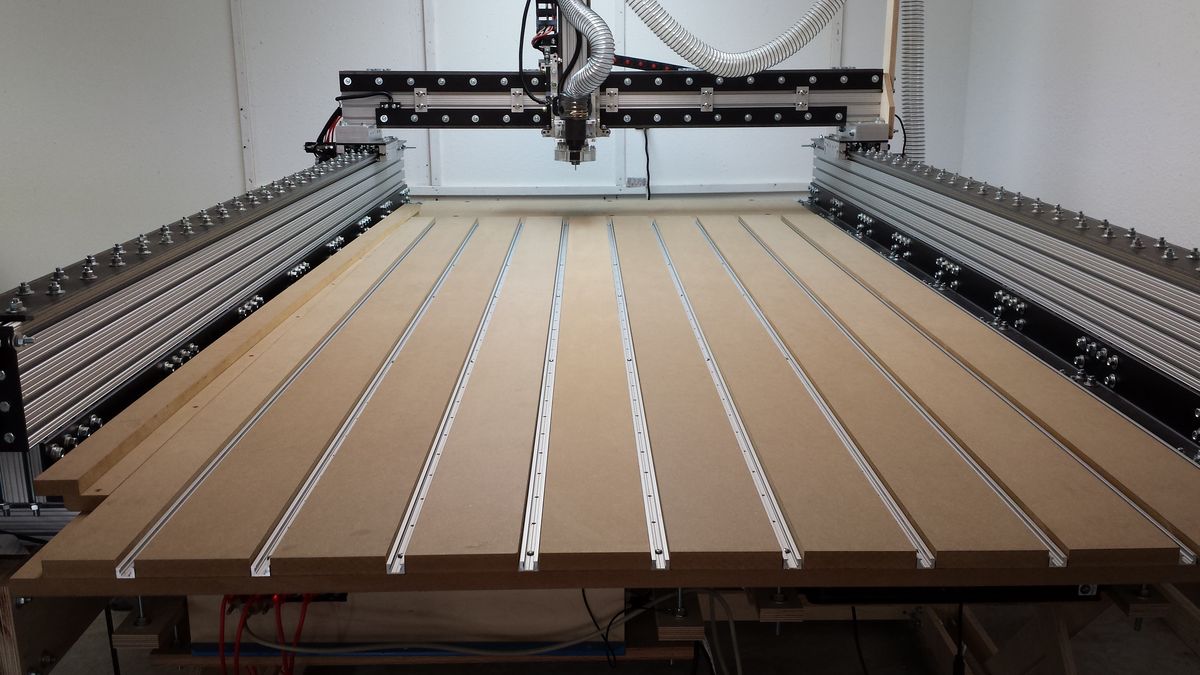

We have movement. Nex step, cable management, and table platform. PID installed and functioning. I have a bunch of 80/20 8ft 1050 extrusions coming for the clamp table.

-

05-23-2013, 06:17 AM #12

Registered

Registered

- Join Date

- Jun 2012

- Posts

- 817

I've never believed in aluminum extrusion CNC's until I saw your build. Since it is all reinforced with steel and secured with a generous amount of bolts, I imagine a very stiff machine. I've seen the website for the KRM, but didn't realize how well engineered this machine is. Thanks for sharing your build.

-

05-24-2013, 05:44 PM #13

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 16

Got the MDF for the base table a few days ago. I have 12 8 ft t-tracks coming. Hope to get them next week. Ordered the cable track kits from CNCRP yesterday.

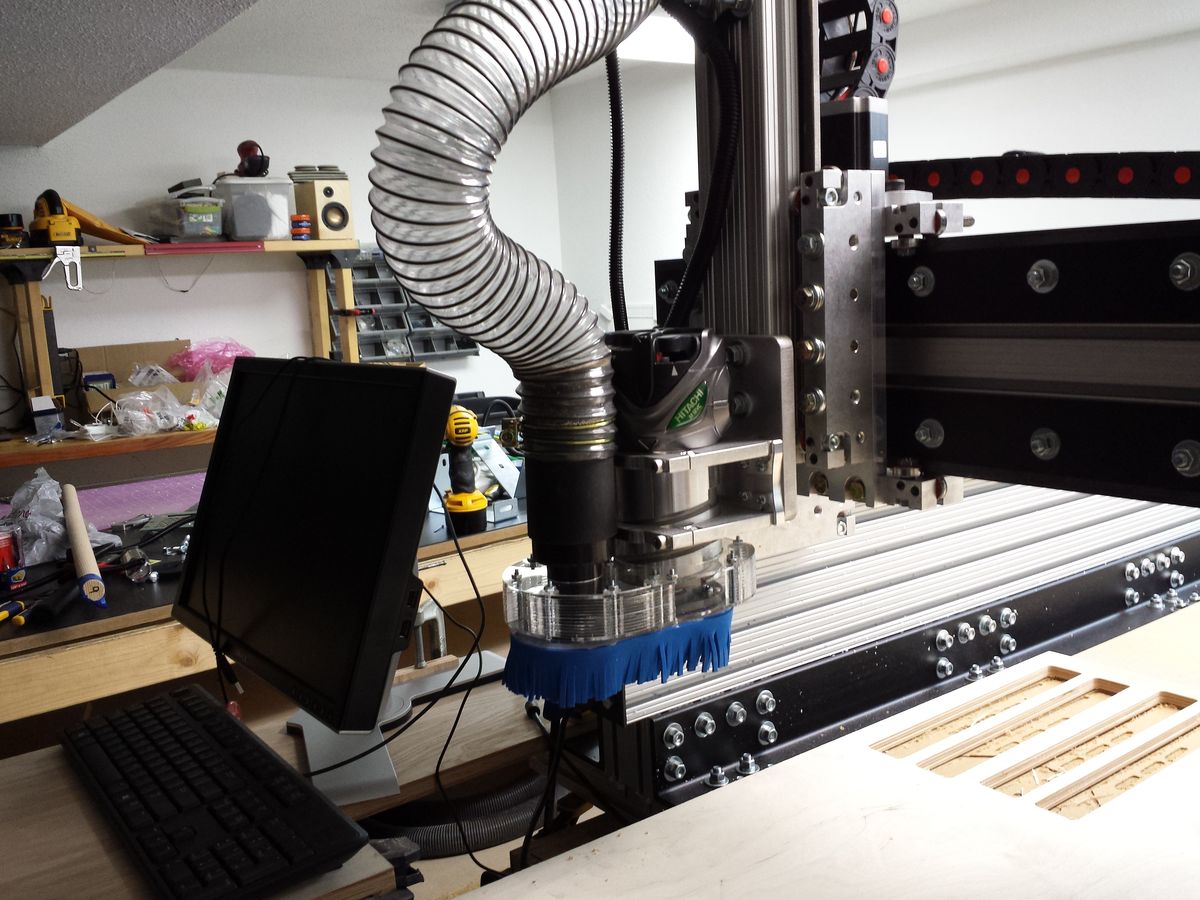

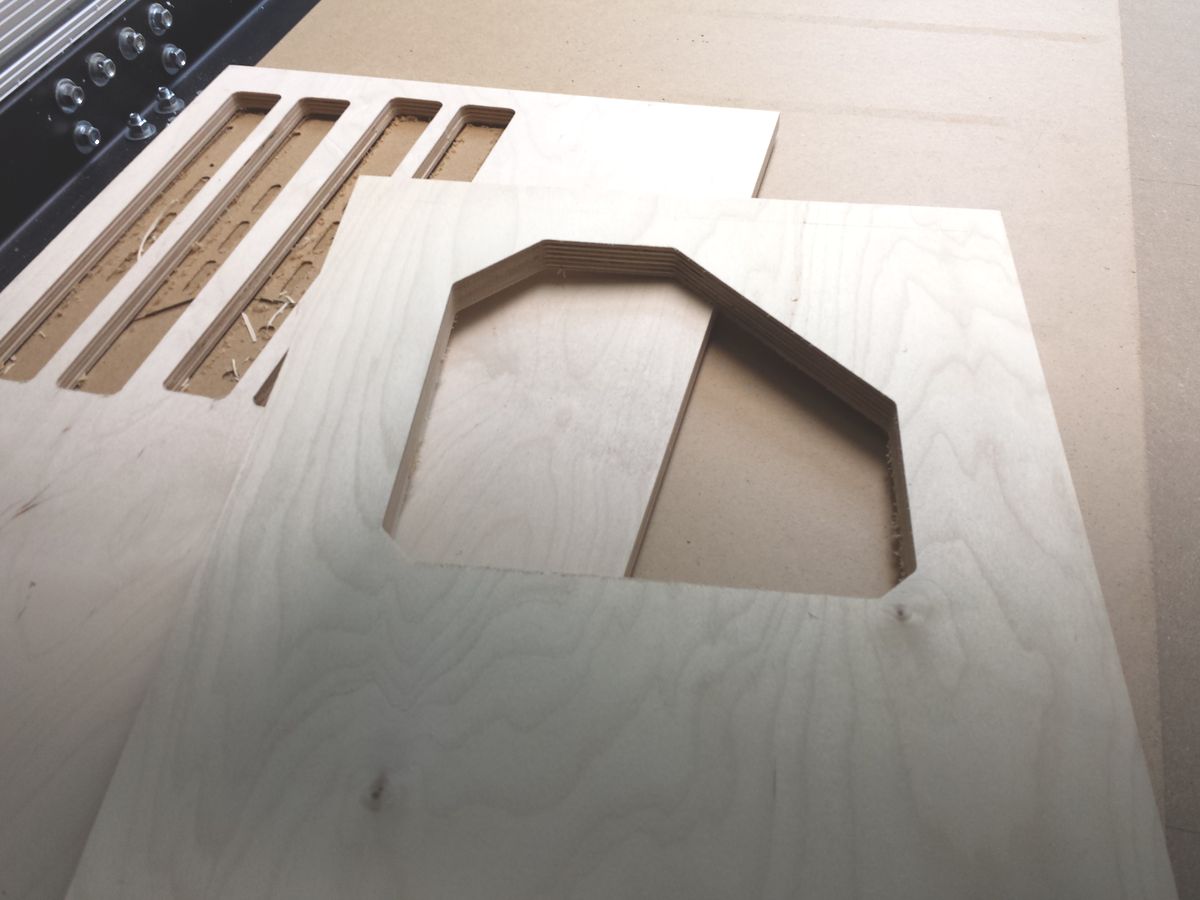

Made some yellow dust last night. The business below my office uses a lot of sintra - I got some scraps from them for testing. This was done with a 1/8th bit, so the holes are a little big and the outside dimensions are small. But it works!

It took a few tries to get the right amount of double sided tape - no clamping system yet.

KRMx02 First run - YouTube

-

05-25-2013, 01:19 AM #14

Registered

Registered

- Join Date

- Mar 2012

- Posts

- 276

What kinda feed rate you getting out of that?

My CNC Router Build - http://tinyurl.com/c3vs3ca

-

05-27-2013, 06:25 AM #15

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 16

-

06-06-2013, 05:50 PM #16

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 16

I'm overdue for an update. Getting very close to calling the build complete.

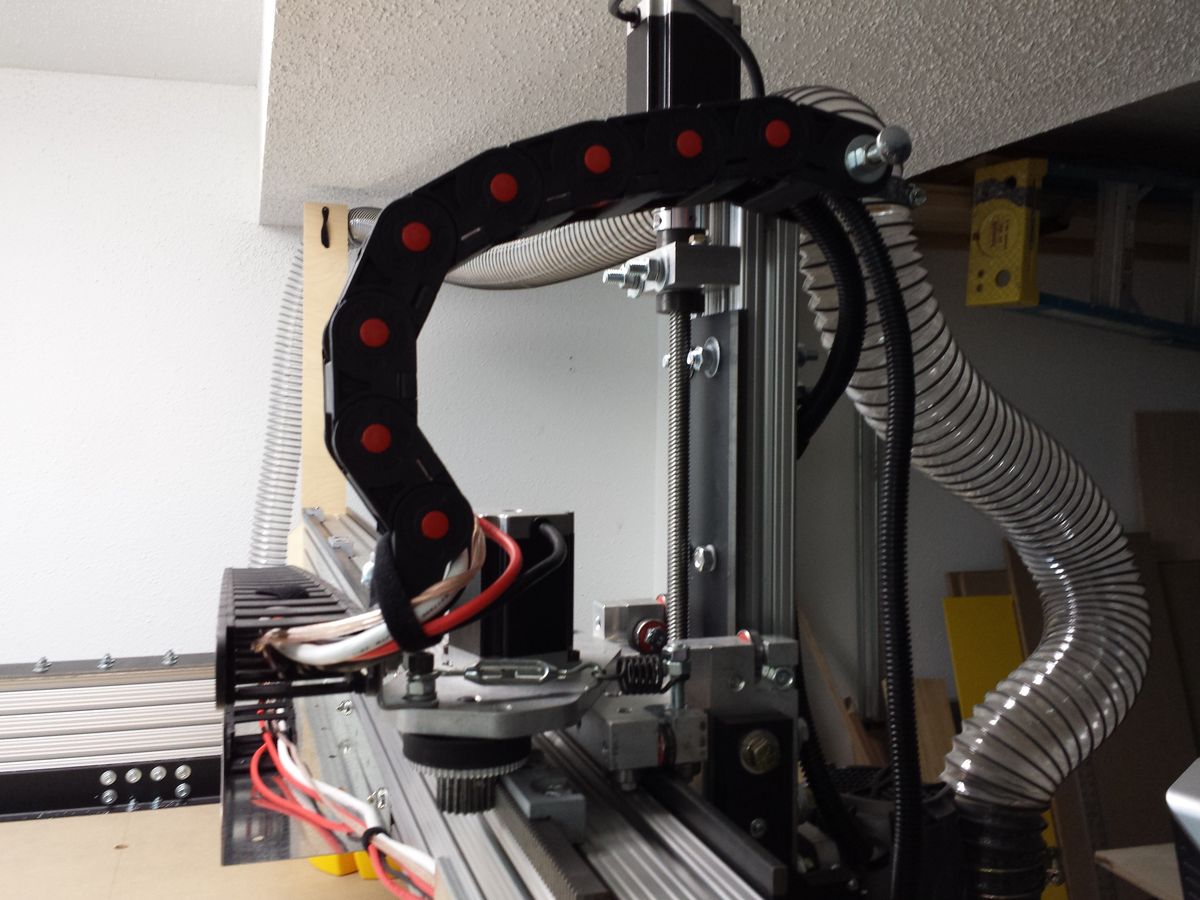

The cable track system from CNCRP worked out well. It wasn't a perfect fit for how they attach to their 48x96, but the hardware was workable without too much trouble.

Clamp table is getting close to being finished. Vac hose routed passably. Cut out some clamps, and then some more clamps. Made one of the gantry braces. Made a couple dust shrouds.

Here's a little walkaround video

http://youtu.be/25JMY2pjSiE

-

06-07-2013, 05:45 AM #17

Registered

Registered

- Join Date

- Nov 2006

- Posts

- 1036

Congrats on a great build!! Couldn't view your last video because it was marked "private".

-

06-07-2013, 01:00 PM #18

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 16

-

06-22-2013, 03:22 PM #19

Registered

Registered

- Join Date

- Jun 2011

- Posts

- 1

Hi Mate,

Very nice build! What size stepper motors did you go with?

-

06-22-2013, 03:36 PM #20

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 16

Thanks!

They are 380 oz Nema 23 from CNCRP - link.

Similar Threads

-

New KRMx02 50x50 Build log (Canada)

By pamcinto in forum CNC Wood Router Project LogReplies: 38Last Post: 08-06-2018, 11:53 PM -

Project KRMx02 (50x102) with Doughty Drives.

By Op4 in forum DIY CNC Router Table MachinesReplies: 32Last Post: 02-09-2015, 11:13 PM -

50x50 Metric Build - KRMX02

By NidalRobb in forum DIY CNC Router Table MachinesReplies: 6Last Post: 03-11-2013, 06:01 PM -

KRMx02 Colors

By msimpson99 in forum DIY CNC Router Table MachinesReplies: 0Last Post: 05-13-2012, 05:35 AM -

Gantry Brace Upgrade for KRMx02 Build

By msimpson99 in forum DIY CNC Router Table MachinesReplies: 0Last Post: 02-16-2012, 09:44 AM

Reply With Quote

Reply With Quote