I'm a very small time knifemaker, and was getting tired of making the knife handles and msc parts by hand, so Ive been dreaming of a CNC machine for about a year now.

I finally saved up enough money to afford a BF20L and just took delivery last week.

So far all I've done is unpack the stand and uncrate the mill. My first problem is that this thing is heavier than I thought. Is it a really bad idea for a newby to take the head off so I can lift it and assemble on stand, or will I really be messing up factory alignment that way?

Cheers!

Results 1 to 12 of 12

-

05-22-2013, 04:07 PM #1

Registered

Registered

- Join Date

- May 2013

- Posts

- 9

Just got a new optimum BF20L and Im pretty lost, but excited!

-

05-22-2013, 04:33 PM #2

Member

Member

- Join Date

- Apr 2006

- Posts

- 8159

Taking the head off will only shed about 60 lbs.

If you unbolt the column too that would break it up into manageable hunks by yourself, that's how I did it.

g0704.com pics

You'll need to check tram anyway but if you can lift the full mill as is with the help of a friend or two or use a hoist of some sort, tramming will easier.

Videos here on tramming Projects2

If you take the head off read #2 here. FAQs

Good luck, Hosshttp://www.hossmachine.info - Gosh, you've... really got some nice toys here. - Roy Batty -- http://www.g0704.com - http://www.bf20.com - http://www.g0602.com

-

05-23-2013, 01:33 AM #3

Registered

Registered

- Join Date

- May 2013

- Posts

- 9

Thanks very much for the pointer to all your info! Ive got lots of reading to do.

I think I might see if I can borrow a hoist so I dont have to take the whole thing apart to get it up on the stand.

-

05-23-2013, 01:38 AM #4

Neuer Benutzer

Neuer Benutzer

- Join Date

- Jan 2013

- Posts

- 630

You are going to end up taking it apart anyway. Might as well learn the machine ins and outs while getting it on the stand. I had mine for all of 2 hours before I completely tore it apart....

-

05-23-2013, 09:36 AM #5

Member

Member

- Join Date

- May 2008

- Posts

- 1185

If you pull the table and head two guys can lift it easy.

The table is only a few bolts. The head is 4 with a hidden hex bolt to prevent it from falling off.

-

05-27-2013, 07:06 PM #6

Registered

Registered

- Join Date

- May 2013

- Posts

- 9

Ya I sized up the job, and taking it apart is just way more manageable. I bolted my stand to the concrete and Ive got the head off so far. I was hoping my version has the upgraded 3 bolts the newer grizzlies seem to, but its only go the single.

-

05-27-2013, 11:02 PM #7

Registered

Registered

- Join Date

- May 2013

- Posts

- 9

Well I almost got it back together but not quite. I took some pics of it in ripped apart stage.

I was doing some floor milling to play with it first though, and I did the break in.

I knew that the stock leadscrews would have some backlash, but it's pretty bad. 0.006 on x and 0.008 on y.

Once I can afford some ballscrews I'll be getting those for sure.

-

05-27-2013, 11:10 PM #8

Registered

Registered

- Join Date

- Dec 2012

- Posts

- 390

-

05-27-2013, 11:12 PM #9

Registered

Registered

- Join Date

- May 2013

- Posts

- 9

-

01-23-2014, 11:13 PM #10

Registered

Registered

- Join Date

- May 2013

- Posts

- 9

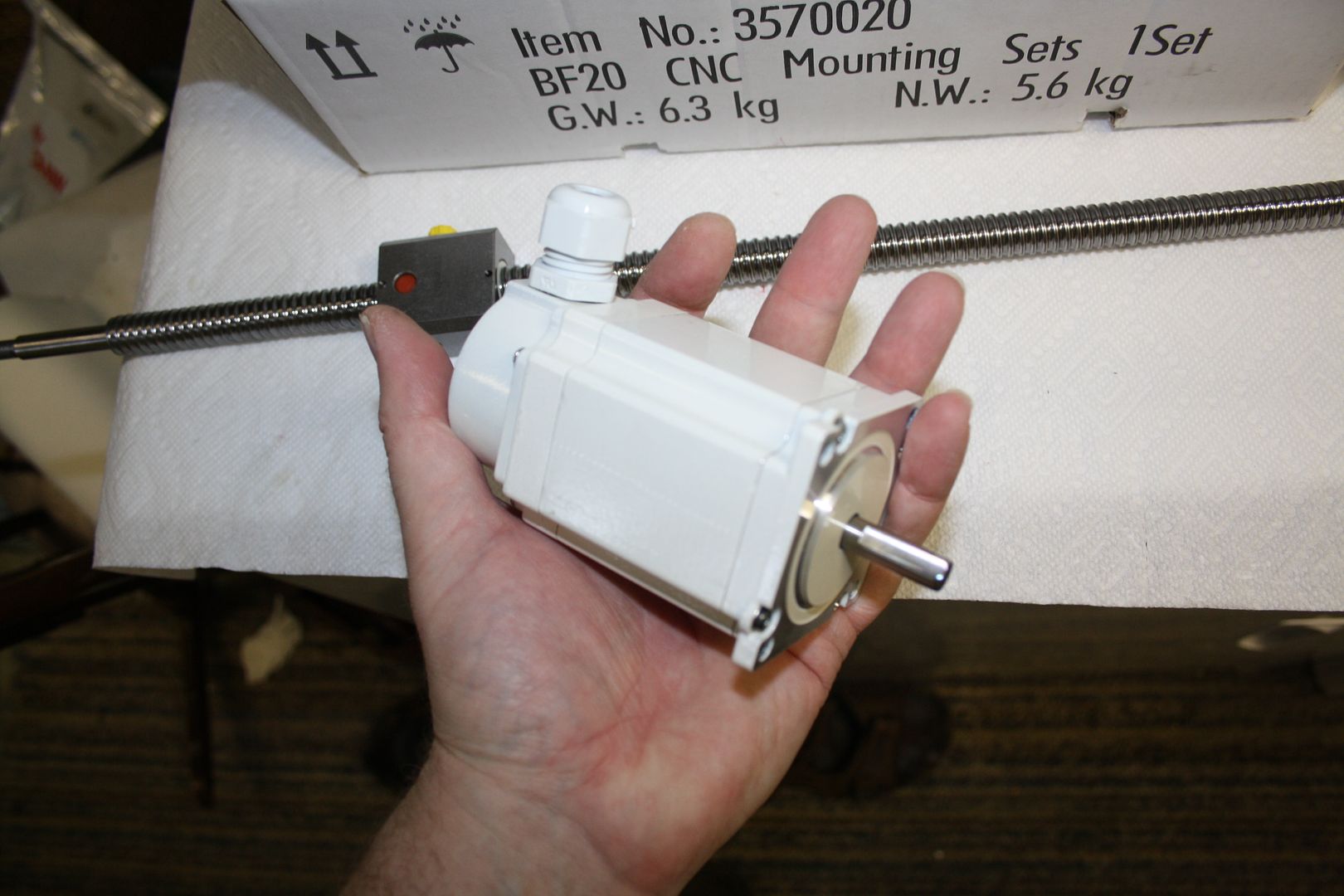

Hey all. I have a rule about earning the money first before I upgrade, so its taken me this long to save up for CNC upgrade parts. I ordered from optimum before christmas and just go the parts in yesterday. Stepper, pulleys, belts, ballscrews all here. Now I gotta find some instructions on what to do, and figure out what kind of gecko drive I need.

This might take me awhile but I'll get it done one way or another.

-

01-23-2014, 11:38 PM #11

Member

Member

- Join Date

- Apr 2006

- Posts

- 8159

I have the optimum cnc conversion pdf I can send you, it doesn't appear to be available on their site now.

pm me your email address if you want.

Hosshttp://www.hossmachine.info - Gosh, you've... really got some nice toys here. - Roy Batty -- http://www.g0704.com - http://www.bf20.com - http://www.g0602.com

-

02-15-2017, 12:11 AM #12

Registered

Registered

- Join Date

- Feb 2017

- Posts

- 3

Re: Just got a new optimum BF20L and Im pretty lost, but excited!

Hey Hoss, can you send those to me? I also plan to get FDM BF20L in Ukraine, and wonder about budget variant for that mini-mill cnc conversion, how do you think, is it possible to go at first without ballscrew conversion? Also I wonder if I really need those massive NEMA34 1200 oz steppers or I could be fine, maybe with less speed, but with NEMA 23 for 420 oz? Thx.

Similar Threads

-

RF Excited Co2 Laser refill

By pinal in forum News AnnouncementsReplies: 0Last Post: 06-27-2013, 05:07 PM -

Optimum BF20L CNC conversion using the Smooth Stepper

By Mad Welder in forum Benchtop MachinesReplies: 601Last Post: 03-25-2013, 12:47 AM -

Excited to take delivery on my PCNC1100

By Boss&Sons LLC in forum Tormach Personal CNC MillReplies: 12Last Post: 07-09-2012, 03:48 AM -

Optimum BF20L CNC conversion

By JanHenning in forum Vertical Mill, Lathe Project LogReplies: 19Last Post: 03-11-2009, 05:09 PM -

OPTIMUM BF20L mill, z-travel exactly from table height ?

By vroemm in forum Uncategorised MetalWorking MachinesReplies: 1Last Post: 01-19-2009, 10:01 PM

Reply With Quote

Reply With Quote