I sent my check to purchase a brand new Patriot. As of today they have not cashed my check, so I thought maybe I would post what I go through for one year as a new owner. I will post pictures as I go through my setup and performance and for the haters problems and issues I have. So please ask me questions and I will try to keep up with them as I go along. So right now I am waiting for my machine to ship.When it arrives I will document my experience good and bad. Oh my WIFE said after spending what I did I had better scream like a girl with excitement when it arrives. We will see.

Results 1 to 15 of 15

-

08-06-2013, 11:57 AM #1

Registered

Registered

- Join Date

- Jul 2013

- Posts

- 25

08/06/13 Just bought a new Patriot. Follow me (with pics) for a year.

-

08-07-2013, 03:24 PM #2

Registered

Registered

- Join Date

- Jul 2013

- Posts

- 25

Well the check has been cashed so now I am waiting for the shipping date. Does anyone know where they ship from? I am assuming they are in Las Vegas.

-

08-14-2013, 03:37 PM #3

Registered

Registered

- Join Date

- Jul 2013

- Posts

- 25

Well tomorrow will be the big DAY .My fully CNC machine will delivered on the fifteen of August. I am running the sub-panel to my garage right now. I won't have much to do until it arrives. Toys, toys, toys, I have a lot of stuff to buy over the next couple of months.

-

08-16-2013, 12:35 AM #4

Registered

Registered

- Join Date

- Dec 2011

- Posts

- 21

Welcome to the club, it's a great machine! Better can be had, but at what price? Be prepared to do some tinkering. How much depends how fussy you are. It is totally useable as it arrives, but what fun would it be to just leave it at that?

ENJOY!!!!!!

-

08-20-2013, 06:48 AM #5

Registered

Registered

- Join Date

- Jul 2013

- Posts

- 25

My Patriot arrived today. Here are some pics of the machine and the tools in and out of the crate. My buddy will be over tomorrow to help me get it completely set up...

Attachment 196916

Attachment 196918

Attachment 196920

Attachment 196922

Attachment 196924

-

08-24-2013, 04:02 AM #6

Registered

Registered

- Join Date

- Mar 2010

- Posts

- 18

Looks good. Got mine a few months back...

Sent from my KFTT using Tapatalk 2

-

09-05-2013, 05:22 AM #7

Registered

Registered

- Join Date

- Jul 2013

- Posts

- 25

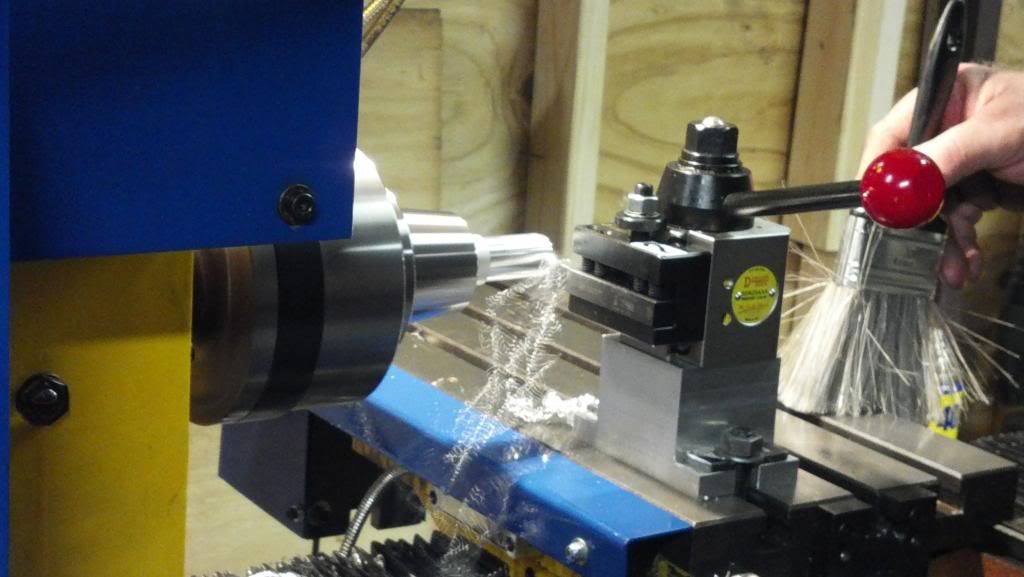

I have always wondered why you stop seeing posts on some new machine threads, now I know. I have have been trying to learn G-code and tune my machine on the fly. NOT a cheap or fast way to approach a learning curve quite this steep. Did I mention I have industrial electronics background and a very limited amount of machining knowledge. So anyway let's post some pics.

Attachment 199210

This photo shows my web cam and some of the first chips I made.

Attachment 199212

And here we see the bellows pulled back. This shown the new center mounted screw for the lathe bed.

Attachment 199214

Here we can see the tailstock hardware and adj. knob.

Attachment 199216

This is my pain in the A$$ oil leak I am trying to seal the threads of.

Attachment 199218

Some people have asked about the index pulse. This is what came on my machine.

Attachment 199220

And my first mod. Let there be light! I put in a shop light to light my way.

Attachment 199222

Attachment 199224

Attachment 199226

Attachment 199228

-

09-06-2013, 05:39 PM #8

Registered

Registered

- Join Date

- May 2013

- Posts

- 1

What did you do about the leak? I noticed when i got mine in it had leaked a little oil as well, but for now has seem to stop.

-Joe

-

09-13-2013, 01:33 PM #9

Registered

Registered

- Join Date

- Jul 2013

- Posts

- 25

I e-mailed shoptask and they sent me a new fluid level indicator. They were willing to take care of it without issue.

-

09-15-2013, 02:19 PM #10

Registered

Registered

- Join Date

- Jul 2013

- Posts

- 25

The shipping for the Patriot was about what my estimate of $400.That was from Las vegas to Spokane WA. I good rate for the size and weight ie. 1012 lbs. It looks as though I won't be doing much with the machine quite yet. But early November I should be able to show some of the basic capability of the cnc mill & lathe. If anyone has questions feel free to ask I will help all I can. If you are having electrical problems shoot them to me. I get paid a lot at work to do what I do so give me a shout, I am always looking for a challenge.

-

10-23-2013, 07:06 AM #11

Registered

Registered

- Join Date

- Aug 2012

- Posts

- 27

I have a love/hate relationship with my Patriot. It will certainly make my parts, but it takes constant attention and tweaking to get things right. The best investment I made was to purchase the DRO. It has prevented garbage parts a number of times when I look up before a cut and see the physical DRO is significantly different from the Mach3 DRO. Temperature changes effect the machine drastically. 5 degrees F can knock it out of whack by as much as .005.

But I'm glad I bought it. I designed a custom electronic cigarette, took the design to a machine shop and they wanted more than the cost of the Patriot for prototypes. I bought the machine and it has much more than paid for itself.

I use that exact same light! :P Some of my machine mods that have worked quite well:

Dorian QCTP + riser and Smithy manual 5C collet chuck

Modified TV tray allows the keyboard, mouse and monitor to swivel. Mouse pad has decimal equivalents in 64ths

-

12-24-2013, 06:42 PM #12

Registered

Registered

- Join Date

- Dec 2013

- Posts

- 4

Genisis style intended as a hybrid? Good looking from the outside! I guess repeatability hangs on keeping the shop at a somewhat steady temperature?

-

01-28-2014, 05:36 AM #13

Registered

Registered

- Join Date

- Aug 2012

- Posts

- 27

Yes indeed

Since my last post, I've moved my pre-production operations over to Haas equipment at The Geek Group in Grand Rapids, MI. With their guidance, I've taken what I learned from using the Patriot and am applying it to their ST-20Y. The Geek Group is a pretty unique place where they let you play with incredibly expensive toys for a very nominal membership fee. It's the only place on earth where they let you come in and play around with a $1million Kuka 7 axis industrial robot and then walk across the room to tinker with a Haas ST-20Y, VF-2 and SR-100.

Since my last post, I've moved my pre-production operations over to Haas equipment at The Geek Group in Grand Rapids, MI. With their guidance, I've taken what I learned from using the Patriot and am applying it to their ST-20Y. The Geek Group is a pretty unique place where they let you play with incredibly expensive toys for a very nominal membership fee. It's the only place on earth where they let you come in and play around with a $1million Kuka 7 axis industrial robot and then walk across the room to tinker with a Haas ST-20Y, VF-2 and SR-100.

-

01-28-2014, 06:24 AM #14

Registered

Registered

- Join Date

- Dec 2013

- Posts

- 4

sooo...I take it you'll be selling your shopmaster to me now for an awesome price? LOL

Good luck with your production and overall goals!

On a more serious note...would you buy a shopmaster again if production was not an issue? Curious about that since I sorta, kinda came to, a perhaps premature, decision that the shopmaster is really only for home/hobby and perhaps some (light?)production.

-

01-29-2014, 08:54 AM #15

Registered

Registered

- Join Date

- Aug 2012

- Posts

- 27

If I wasn't trying to hit .001" or better tolerances, then it would be a good machine. Not great, but enough to get quite alot done. It's very good for proof of concept and prototyping work, especially if space and power are a big concern which they were for me at the time. I also started with absolutely no machining or CNC programming experience and the Patriot allowed me to learn on something fairly inexpensive. 2 years after buying the Shopmaster, I'm now running and programming a professional grade machine with very few hiccups. I think it's a good teaching tool and there are tons of parts you can make with it...my parts are simply not among them.

I've been working on some off the wall ideas to retrofit the Patriot with better components once I have some real industrial equipment of my own. Higher grade ballscrews, double ballnuts, servos, etc. The intent is to turn it into a second op lathe for half the cost of something like the Haas OL-1. The crazy idea is to mill off the dovetails and replace them with linear rails. Not sure if I'll actually go through with that, but if I do there will certainly be a build thread

Similar Threads

-

First machine build after 5 year break (pics)

By painter in forum CNC Wood Router Project LogReplies: 54Last Post: 04-08-2013, 04:21 AM -

Has anyone bought the new Patriot 4x8 CNC plasma cutting table from Precision Plasma

By pens92 in forum Waterjet General TopicsReplies: 10Last Post: 02-03-2013, 06:15 AM -

Anyone ever bought an X2 and wished they'd bought an X3?

By isaac338 in forum Benchtop MachinesReplies: 17Last Post: 04-15-2008, 04:06 AM -

M.E. Project (pics, lots of pics)

By skmetal7 in forum Community Club HouseReplies: 2Last Post: 01-08-2007, 10:30 AM -

Follow Up Of My Cnc Put Together Now

By chris69randy in forum DIY CNC Router Table MachinesReplies: 16Last Post: 04-16-2005, 08:40 AM

Reply With Quote

Reply With Quote