Hey guys! I just signed up to this forum; I've been lurking around for quite some time and it has been an awesome resource for me! Let me tell you a little about my project. I have always wanted a CNC router for some of my prototype projects. I decided I was going to have a go at building one. I ordered some ballscrews, linear rails...

Nema 23 stepper motor 435oz,in,3.0A

Stepper motor driver DM542A, 24-50VDC

Power Supply 350Watts( 36VDC/9.7A)

Breakout Board DB25

... So then I got busy and the project sat for a few months... Then I was surfing craigslist and found a used 6040 for a deal! I picked it up from the acrylics shop. I was stupid and didn't have them run it for me. Lucky for them I guess! I brought it home and got everything setup. I was having issues with the stepper motors so I replaced them with the stepper motors I purchased for my original build. I was still having issues so I took a peek inside the BLUE control box to see what the problem was. I've read a lot of bad things on this blue box. This is what I found...

So I decided to replace everything with the components I purchased previously. Got that all wired in Sunday evening, and got movement out of the machine last night:banana: I was proud of myself! For being a Mechanic/CAD operator, I thought I did a good job so far! Anyways, I'm having some trouble understanding the motor tuning with mach3, I'm sure this has been covered 100's of times. But I'm not too sure what settings my drivers should be on. At first my steppers were turning VERY VERY SLOWLY with the 8128 steps per inch/65vel/12accel (that the manual told me to tune my motors too).

Okay, Okay, first.. my drivers:

Set to Peak 2.84A since my steppers are rated for 3A

Now the part I'm confused about, but now that I am thinking about it... I think I've figured it out! So my stepper motors are 1.8* that means 200 Steps per rev... Okay, nevermind, I just realized I'm still confused.. I set the steps to 8000 per rev. but I'm thinking now it should be 800 steps per rev. because I have 4 leads at 200 steps per rev? Here is a picture of my options..

Attachment 202008

Then for motor tuning, like I said, the manual instructed me to use: 8128 steps per inch/65vel/12accel

My ball screws have a 5mm pitch = .19685"

Which means to turn 1" I need 5.08 revolutions.

I was messing around with everything last night, trying different combinations... and got it going. Loaded up some G-code and...

http://s1209.photobucket.com/user/ni...13dc0.mp4.html

After that I turned off my controller and computer to make sure all the settings saved. Started it back up and everything was back to as SLOW as can be... even with the exact same settings. As I was jogging my X stepper, it started making noise (like is was hitting a hard limit) and wouldn't turn. I turned the controller off, the ball screw turned easily, no binding. Rebooted, gave it a quick jog again and then the motor completely died...Thankfully I have a spare motor. I'm kinda lost with why it would've done that. Did my settings fry the motor?

Results 1 to 9 of 9

-

09-24-2013, 05:10 PM #1

Registered

Registered

- Join Date

- Sep 2013

- Posts

- 6

6040 Chinese CNC ... bought off craigslist... Haha! Could I get any cheaper!?

-

09-25-2013, 08:49 AM #2

Registered

Registered

- Join Date

- Jul 2012

- Posts

- 19

Hmm I think I see why it didn't work

-

09-27-2013, 01:40 PM #3

Registered

Registered

- Join Date

- Sep 2013

- Posts

- 6

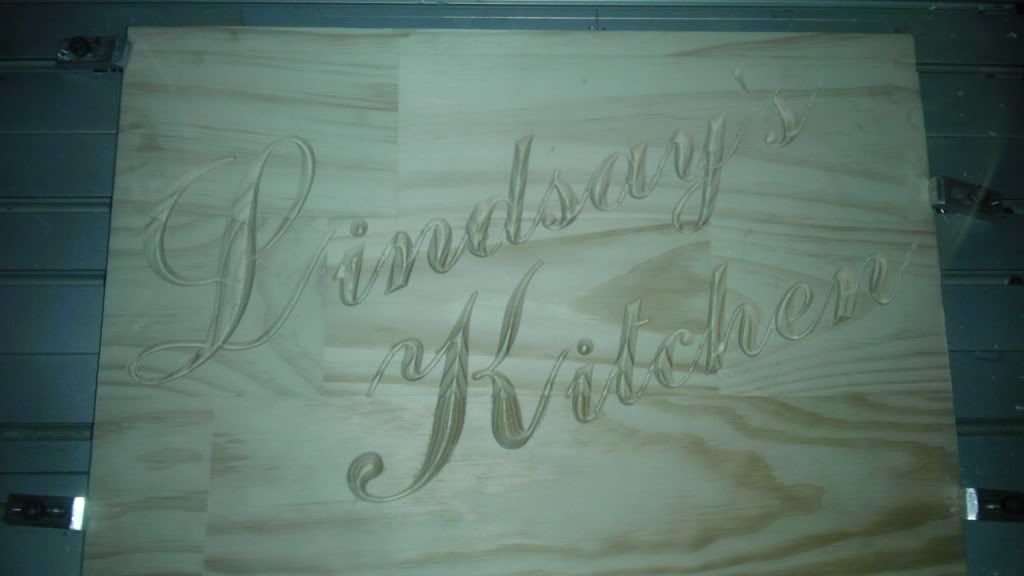

Figured it out! It was quite simple actually. By the end of last night things were going smoothly!

VIDEO0022_zpsc371d28d.mp4 Video by nismo300zxjdm | Photobucket

Now, for some test cuts!

-

09-27-2013, 01:49 PM #4

So what did you have to change to fix it?

Regards

Geoff

-

09-27-2013, 02:16 PM #5

Registered

Registered

- Join Date

- Sep 2013

- Posts

- 6

Set the drivers to 1600 steps per rev. Then calibrated each axis with my runout gauge. Didn't get it quite exact yet but close enough to load a program and run it. Each axis is +/-.005"... I'll get that sorted out this weekend. Then I played with velocity and acceleration until they were smooth. The X axis still sounds a bit funny at times. I'll keep and eye on it. This weekend I'll be running some simple programs to make sure everything is working properly. SO EXCITED!

Oh and by the way, make sure the drivers are powered off when your switch your steps per rev settings, or else the settings won't change.

-

10-03-2013, 01:38 PM #6

Registered

Registered

- Join Date

- Sep 2013

- Posts

- 6

-

10-16-2013, 02:35 PM #7

Member

Member

- Join Date

- Sep 2013

- Posts

- 43

performancevh..are u running a rznc dsp controller ???.what start spd. are u set at...//???

-

10-16-2013, 04:07 PM #8

Registered

Registered

- Join Date

- Sep 2013

- Posts

- 6

No, I'm using Mach3

-

10-16-2013, 05:07 PM #9

Member

Member

- Join Date

- Sep 2013

- Posts

- 43

ok thanks well it back to the board....again

Similar Threads

-

Are you glad to have bought a Chinese made CNC Router?

By rocket67 in forum Chinese MachinesReplies: 244Last Post: 06-25-2023, 09:07 AM -

My Chinese 6040 Experience So Far

By kronick in forum Chinese MachinesReplies: 16Last Post: 05-12-2018, 11:48 AM -

Chinese CNC Router (CNCDIY 6040 )

By Domenicxx in forum Australia, New Zealand Club HouseReplies: 15Last Post: 10-23-2012, 09:08 AM -

Anyone bought advertisting CNC Chinese machine

By cup67 in forum Chinese MachinesReplies: 4Last Post: 12-09-2010, 03:46 AM

Reply With Quote

Reply With Quote