Hi everyone!

I'm pretty new to the forums here, but so far it has been a pretty good source of information for someone more accustomed to PLCs and relays than the finer points of mechanical design.

I'm not completely clueless, however. My old job involved the installation of some pretty high-precision gantry systems. I know about ballscews and linear rails, and the gantry needs to be stiff. I haven't got a clue as to how that happens!

I picked up my parts from Chai/linearmotionbearings2008 on ebay. Since the cost was practically the same for smaller and larger setups, I decided to go with a larger setup.

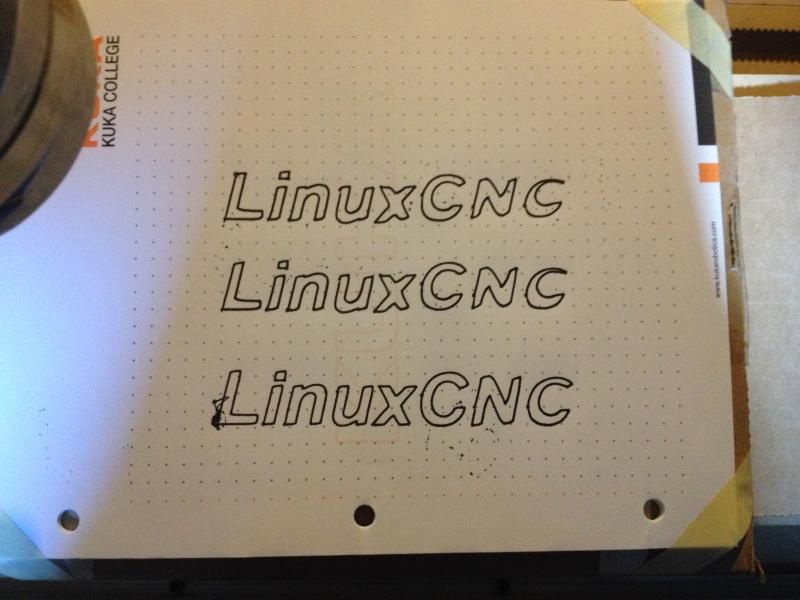

I decided to go with Wantai motors/drivers in my build. Haven't tried them yet. They will be controlled from an old dell pc with a parallel port I picked up off a craigslist yesterday running LinuxCNC.

Most of the build so far I have been "winging it." I had a general idea of how I was going to build it and the structure it would take, but otherwise there was very little planning. I have no drafting experience or software and figured I could slop it together well enough to machine a better design in the future.

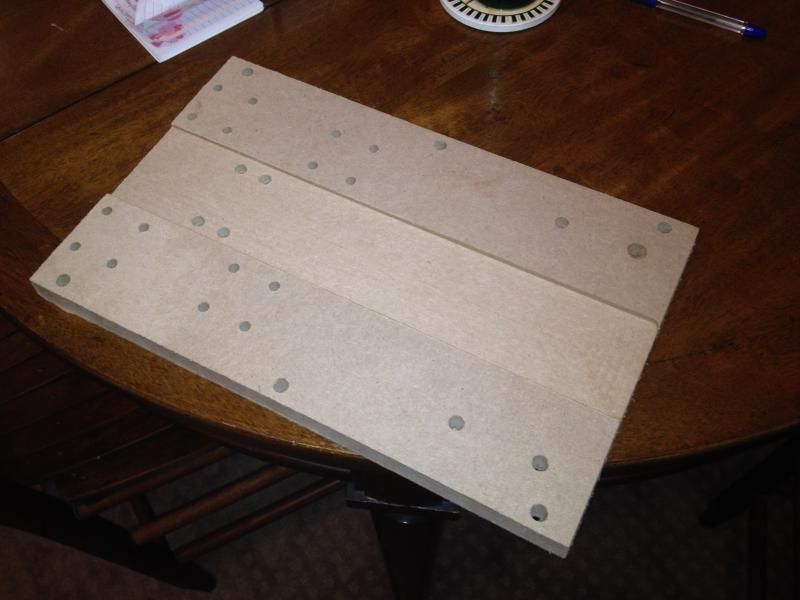

I am building the whole thing out of MDF. Everything is being done by hand. I also have very few tools. I have a drill, a sawzall, and a dremel. I drew up a diagram of all the gantry pieces to cut from the MDF. They were all rectangles to make it easy for the guys at Lowe's to cut it for me on their saw (they still looked at me kinda funny when I handed them a set of drawings, though!). Some pieces had to be re-cut on my father in law's table saw, but otherwise the pieces were close enough to work. Everything else I have done by hand. It has been a long and tedious process, but I'm almost finished.

Anyway, here's the fun part. Pictures!

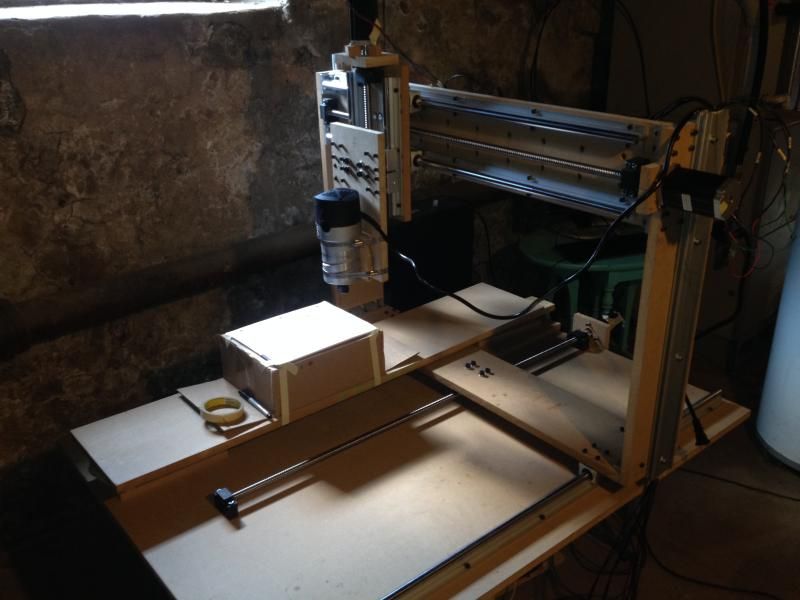

Z axis (note the gap between the bearing blocks and MDF. The ballscrew nut sits appx 4mm higher than the top of the bearing surface. I'm using 4 m5 washers per bolt per bearing to space out that gap...

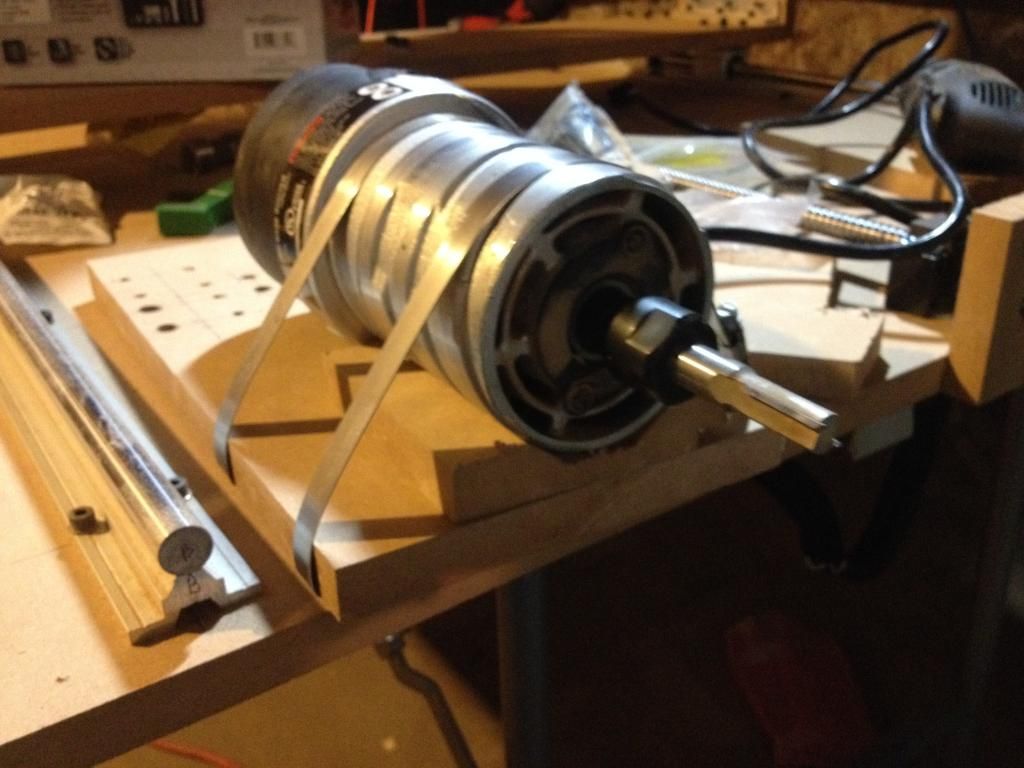

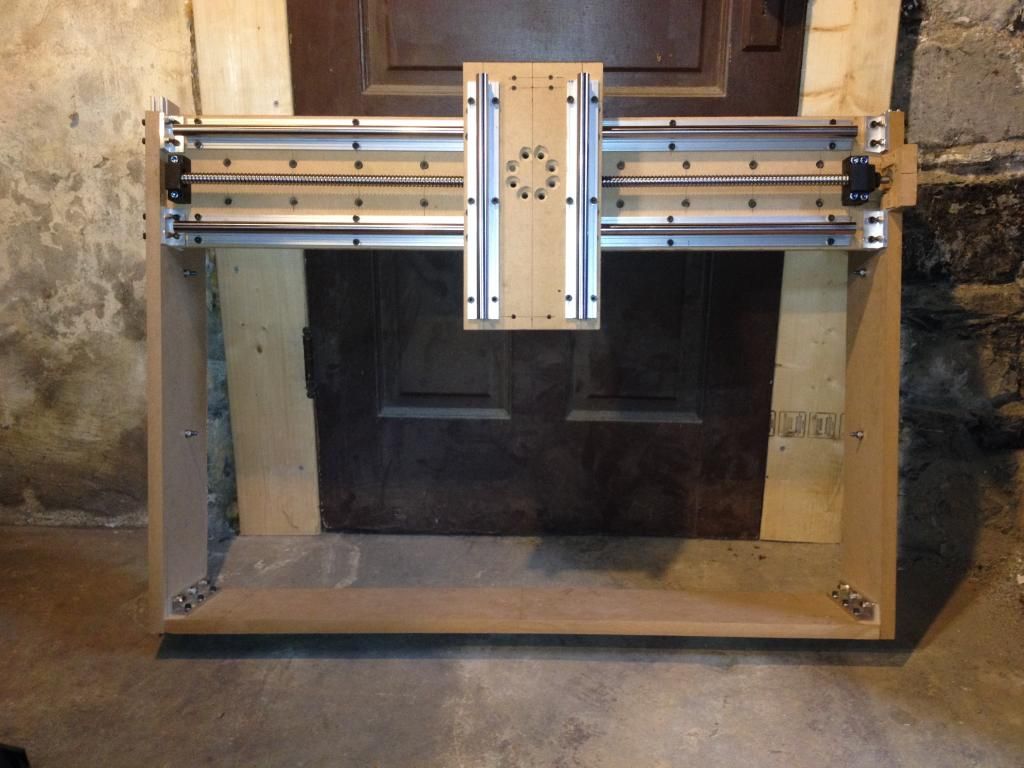

Y axis. I cut and drilled all those alluminum l brackets to help with deflection and torsional rigidity. Again, all I had was a sawzall and a drill and those L brackets started out as 4 ft aluminum angle stock...

Y axis completed

Gantry (almost) Completed

My gantry had some pretty nasty flex in the y direction. I added this aluminum strut to the sides of the gantry to stiffen it up. It worked liked a charm. The strut is leftover from my coworker's recent solar panel installation. He had a bunch sitting around and let me have some

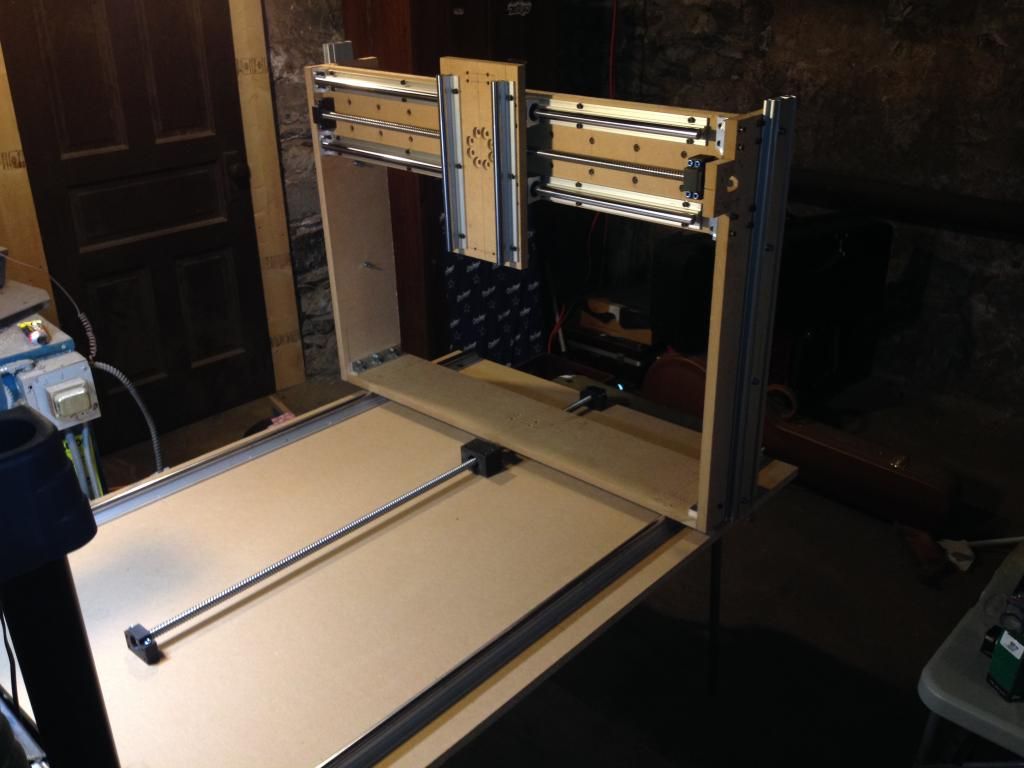

Gantry mocked up on x-axis

I don't have wood clamps for gluing things...

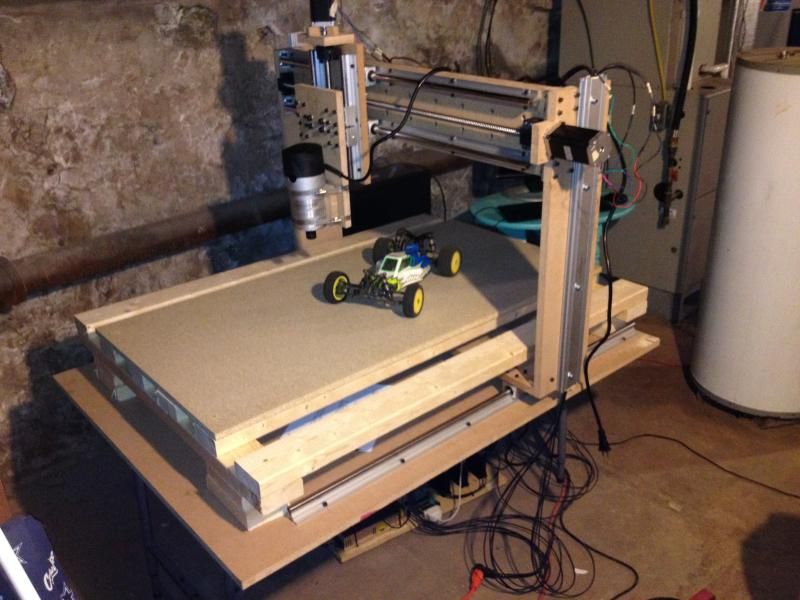

1/10 2wd buggy for scale (I'm a hardcore RC racer, now I'll be able to make my own parts!)

Current state. Waiting to get more bolts to finish up the mechanical side of the build. Yesterday I picked up the harbor freight router and the $50 craigslist computer to control everything.

Results 1 to 20 of 36

-

09-01-2014, 02:33 PM #1

Registered

Registered

- Join Date

- Jul 2014

- Posts

- 27

A Hapless EE Attempts a CNC Build

-

09-01-2014, 05:19 PM #2

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 711

-

09-01-2014, 07:22 PM #3

Registered

Registered

- Join Date

- May 2005

- Posts

- 1662

Re: A Hapless EE Attempts a CNC Build

As alan_3301 points out the gantry is going to go trapezoidal (sp?) . Also the bearings on the x would work better if spaced further apart. Looks like a lot of clearance between z and table, but maybe you have work in mind that requires the space.

Bootstrapping is good fun and you've already got some decent bits for a build #2.figured I could slop it together well enough to machine a better design in the future.

Imo learning by jumping right in is no bad way to go, worst case you're out a sheet of MDF.Anyone who says "It only goes together one way" has no imagination.

-

09-01-2014, 07:53 PM #4

Registered

Registered

- Join Date

- Jul 2014

- Posts

- 27

Re: A Hapless EE Attempts a CNC Build

We had a slogan at my old job. "It's about progress, not perfection." I think that certainly applies here! I can say for sure there's a ton of things I did on this build I will NOT repeat next time!

Thanks for the input on how to improve it. I think I'm too far into this build to make any changes, but I will keep your tips in mind when it comes time to redesign.

-

09-02-2014, 01:52 AM #5

Registered

Registered

- Join Date

- Jun 2009

- Posts

- 122

Re: A Hapless EE Attempts a CNC Build

Even tho you have limited tools to buld this, it looks like you are doing a great job. The best thing is, once you have the machine running, you will be able to make replacement parts for it from "stiffer" materials. You just need to make light cuts to compensate for the flex. I actually ended up machining some steel parts for my new build on my flimsy MDF machine.

-

09-02-2014, 12:02 PM #6

Registered

Registered

- Join Date

- Jul 2014

- Posts

- 27

Re: A Hapless EE Attempts a CNC Build

Wow, that's good to know. I wouldn't have even though of being able to do steel with an MDF machine.

As a quick update, I managed to install LinuxCNC on my control PC yesterday. I have the computer set up for dual boot so I can still use windows on it if need be. As with all steps in the process, I've encountered another road block: I need a graphics card in my computer! Ok, no problem. I hop onto e-bay and after some quick research, I've got a $7 graphics card on the way that should do the trick.

-

09-03-2014, 03:30 AM #7

Registered

Registered

- Join Date

- Jun 2012

- Posts

- 817

Re: A Hapless EE Attempts a CNC Build

That will get you going, but you'll realize limitations real quick. But you can use that machine to make parts for a better one and swap out your drive parts on the new machine. You'll soon find that you'll need to learn some CAD software when your machine is done. You won't get much done without learning that.

But you'll get there. I was exactly in your shoes just a few short years ago. My first machine was pretty simple and primitive, but I learned a lot from it. Good luck!

-

09-03-2014, 05:36 AM #8

Registered

Registered

- Join Date

- Jun 2009

- Posts

- 122

Re: A Hapless EE Attempts a CNC Build

Got to admit it wasnt really machining steel... I had a 10mm "Burr" in the spindle and made a saw cut 36mm hole in 3mm plate out to 38.5mm for a motor mount. Took lots of small cuts and lots more spring cuts. Each cycle of the gcode went around the hole 4 times and then I adjusted the cutter compensation value by 0.5 mm till I got it to where I wanted it to be.

-

09-11-2014, 12:07 PM #9

Registered

Registered

- Join Date

- Jul 2014

- Posts

- 27

Re: A Hapless EE Attempts a CNC Build

A quick update on the project. I installed the graphics card in the computer and now LinuxCNC is happy.

I managed to do some more work on the gantry. It's mounted to the x-axis and two of the motors are installed. I need to make a spacer for the third motor.

I've also got a 500ft spool of wire on the way to do the wiring, but I'm still not sure what I'm going to do for an enclosure. The EE in me wants a nice hoffman enclosure with panduit, screw terminals, junction boxes at the motors, cable glands, and a fan with a filter. The project engineer in me knows I can get away without all that for a while to soften the budget until I manage to find a way to bring in some extra play money with this machine.

-

09-11-2014, 03:26 PM #10

Member

Member

- Join Date

- Dec 2007

- Posts

- 2134

Re: A Hapless EE Attempts a CNC Build

Just make a nice MDF enclosure with a simple fan and filter. Once you have the machine up and running, then you can machine a permanent case as good as you want, surprisingly cheaply.

cheers, IanIt's rumoured that everytime someone buys a TB6560 based board, an engineer cries!

-

09-14-2014, 01:07 AM #11

Registered

Registered

- Join Date

- Jul 2014

- Posts

- 27

Re: A Hapless EE Attempts a CNC Build

It sounds like a good idea, but I'm just not keen on putting electrical equipment in and MDF box.

I made some progress today. With some dremel work and two giant hose clamps, I've got my router mounted up. I am quite pleased with how sturdy it is like this, considering the hose clamps were my back up option when I went to Lowe's today.

I ordered some wire from automationdirect and it should be here monday. Once that shows up, the fun will really begin!

-

09-14-2014, 08:04 AM #12

Registered

Registered

- Join Date

- Jan 2008

- Posts

- 853

Re: A Hapless EE Attempts a CNC Build

Nick, I have used hose clamps and they work if they are firmly mounted. In your picture, it looks like the clamps make a complete loop around the Z plate. Is this true? I think that tightening the clamps the way you need to will cause the MDF to bend up, and you loose your clamping.

Can you make the clamp band go straight back to the MDF right by the double thickness? If you can bolt the clamp to the side of the MDF it won't have to bend around the MDF, and the whole kit should stay very secure.

Paul Rowntree

Vectric Gadgets, WarpDriver, StandingWave and Topo available at PaulRowntree.weebly.com

-

09-16-2014, 01:48 AM #13

Registered

Registered

- Join Date

- Jul 2014

- Posts

- 27

Re: A Hapless EE Attempts a CNC Build

Paul, I'm thinking my hose clamps just have to hold on long enough to machine an actual router mount. But like I said, it is surprisingly solid the way it is now. We'll see how it holds up to cutting force in a few days.

Anyway, for today's update I managed to get some electrical work done. I ran wires for all three motor and labeled them with sharpie and masking tape! The whole time I was thinking about that nice label printer we have at work... And I came up with a "panel" as well. I used a spare chunk of MDF to mount the power supply, stepper drives, and breakout board to. If I designed something like this, I am sure I would be fired! Hopefully tomorrow I can have all the wiring finished and maybe get some motion out of this thing!

-

09-17-2014, 11:46 AM #14

Registered

Registered

- Join Date

- Jul 2014

- Posts

- 27

Re: A Hapless EE Attempts a CNC Build

Not much work done last night, but I did get the wiring verified between the db25 breakout board, drivers, and motors. I managed to get the x-axis moving last night! This is the most exciting part now, seeing everything come together!

-

09-20-2014, 08:04 PM #15

Registered

Registered

- Join Date

- Jul 2014

- Posts

- 27

-

09-23-2014, 02:01 AM #16

Registered

Registered

- Join Date

- Jul 2014

- Posts

- 27

-

09-25-2014, 01:50 AM #17

Registered

Registered

- Join Date

- Jul 2014

- Posts

- 27

-

09-25-2014, 02:01 AM #18

Registered

Registered

- Join Date

- Jan 2008

- Posts

- 853

Re: A Hapless EE Attempts a CNC Build

Congratulations! And good pick of projects for the first run!

Paul Rowntree

Vectric Gadgets, WarpDriver, StandingWave and Topo available at PaulRowntree.weebly.com

-

10-01-2014, 02:07 AM #19

Registered

Registered

- Join Date

- Jul 2014

- Posts

- 27

Re: A Hapless EE Attempts a CNC Build

so after an early success, I have been experiencing some failures. For instance, I burned my bit because my feed rate was too low (wish I would have knew that before I burned it. lesson learned). Not only that, I set off the smoke detector in my basement which sent my wife barreling down the stairs "OH MY GOD IS EVERYTHING OKAY?"

After I stop my machine, I realize the air is filled with a fine haze. I turn around to look at my shopvac and the wall behind it is plastered with MDF dust. I think to myself "what's going on here..." and try sucking up a pile of dust I just swept up. It shoots straight out the back of my vac at the wall! Turns out I didn't have my filter the whole way on! Stupid harbor freight instructions (really, stupid me!) LOL

So anyway, after those... learning experiences... I decided to do some more research on cutting and have a new end mill on its way that is better suited to my machine and my application (MDF for now). I've also started contemplating a feed rate and spindle speed calculator so I can avoid further learning experiences.

-

10-03-2014, 01:08 AM #20

Registered

Registered

- Join Date

- Jul 2014

- Posts

- 27

Re: A Hapless EE Attempts a CNC Build

That new bit worked like a charm! It cut right through the MDF and wasn't even warm to the touch afterwards. I don't think I have to worry about burning it up any time soon.

Ebay link to the bit I used. It's a 1/4" single flute carbide end mill. Since I couldn't change my router speed or increase my feed rate, going from a 2 to a 1 flute sounded like the best solution. For anyone else looking for advice on good MDF bit, this is it!

Similar Threads

-

Build Thread - 80/20 5X10 Woodworking CNC Build

By jsantos in forum CNC Wood Router Project LogReplies: 70Last Post: 08-20-2014, 03:15 AM -

Need some direction to build a small machine to allow me to build a larger one

By Dman65 in forum DIY CNC Router Table MachinesReplies: 3Last Post: 01-05-2013, 05:24 AM -

Mint's Build Aluminum/Steel Build thread.

By FreshMint in forum Maintenance DIY DiscussionReplies: 0Last Post: 10-31-2011, 04:18 AM -

Newbie - To build or not to build Router/Plasma Table

By dfranks in forum Waterjet General TopicsReplies: 10Last Post: 04-08-2011, 05:16 AM

Reply With Quote

Reply With Quote