I'm starting my planning to convert my lathe to CNC today. I'm starting by dissembling it but I'm running into problems.

I'm trying to take the z leadscrew off but I can't.

What is this little thing? It is not screwed in from the back but the parter here is tapped? Should I just drill it out? Or just use a screw extractor?

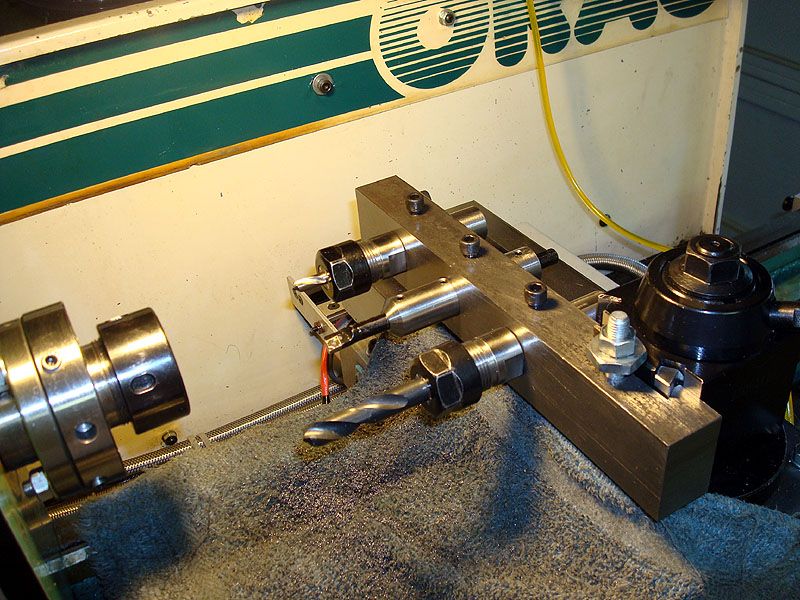

Attachment 214114

Attachment 214116

Thread: 8x12/8x14 Lathe CNC Conversion

Results 1 to 18 of 18

-

12-18-2013, 04:18 AM #1

Registered

Registered

- Join Date

- Dec 2009

- Posts

- 61

8x12/8x14 Lathe CNC Conversion

-

12-18-2013, 05:14 AM #2

Registered

Registered

- Join Date

- Jan 2008

- Posts

- 1529

That's an alignment pin. The inside is threaded so you extract it. I don't what what the correct tool is, but you usually put a bolt in and then use pliers or similar to pull the pin out

7xCNC.com - CNC info for the minilathe (7x10, 7x12, 7x14, 7x16)

-

12-18-2013, 06:00 AM #3

Registered

Registered

- Join Date

- Dec 2009

- Posts

- 61

That makes a ton of sense. Already got it out by hitting the side of the block with a malet and then fitting a wedge in the gap and hammering it in. Not my smartest move. The pins are bent. Hopefully there alignment holes are ok... What do you think?

If the pins are a standard size should I buy some rod or is accuracy received by turning on a manual lathe sufficient?

Sent from my Nexus 10 using Tapatalk 2

-

12-18-2013, 09:36 AM #4

Registered

Registered

- Join Date

- Dec 2009

- Posts

- 61

Im getting rid of the compound slide for increased rigidyity, I would like to add more bolts in my replacement so that I can have more overlap between the stress cones, however the bolts seem to be some weird size. They are 20 threads per inch, but they are only .232" major diameter. Are they jus poorly made bolts or something weird? I'm thinking 8 bolts instead of the original 2.

-

12-18-2013, 10:16 AM #5

Registered

Registered

- Join Date

- Sep 2012

- Posts

- 323

I find it hard to be leave that you would find imperial hardware on a china machine. The major diameter would suggest an M6 bolt. And if your are sure on the 20 TPI, a metric pitch of 1.25 is very close to 20 TPI. Now I have never seen a M6 x 1.25 bolt, but they could be out there. A M6 x 1 is also close to a 1/4-28. I found that a few co-workers have put a M6 x 1 bolt into a 1/4-28 threaded hole.

Maybe I'm wrong, and someone can come in a correct me?

Andrew

-

12-18-2013, 10:39 AM #6

Registered

Registered

- Join Date

- Dec 2009

- Posts

- 61

major diameter is .232"

20/21 threads in roughly 22mm

Should I just buy a different one, use mine, or is it worht it o make my own? It sounds like a fun project.

I have a question: I have heard conlficting oppinions on machining ball scres, can I do it on a large lathe? Will it be precise enough?

-

12-18-2013, 01:08 PM #7

Gold Member

Gold Member

- Join Date

- Jun 2004

- Posts

- 6618

I machined a few sets of ball screws on this very lathe. Mine was 7/12. I used brazed carbide cutters the first time and did not anneal the ends of the screw. Very poor results to start with getting through the hard shell. Wound up okay though as it gets softer and easier to turn in the middle.

The second set of screws I did were identical. Thomson 5/8" screws from McMaster Carr.

I wrapped a wet rag around the end so heat would not transfer past where I was machining and heated the end up to anneal. That is the way to do it. I was able to turn it very easily with the 7/12 including some 7/16 20 threads. Much more professional output when annealed and the lathe didn't complain nearly as much. Lee

Lee

-

12-18-2013, 07:41 PM #8

Registered

Registered

- Join Date

- Dec 2009

- Posts

- 61

I plan on doing it on a hardinge hlv lathe so the machine is pretty rigid.

Did you just have problems with the rigidity of the machine or was the ball screw flexing.

I was thinking, so I was looking at how somone else converted the machine and they had the nut on the back of the machine and the ball screw poking out. However that would require either a 600mm ball screw or for me to extend a 300mm one. I s extending a ballscrew kosher? I was thinking of making a sleeve and brazing it or drilling a hole in the end and machining the extension to have a nipple to go in the hole. I'm leaning toward the sleeve as I feel that will be easier to maintain alignment with.

These are the ball screws I'm looking at.

http://www.ebay.com/itm/2-Anti-bachl...item3a547a2722

The inside of the z slid is unfortunetly smaller than the ball nut, so I can machine the ball nut smaller, or I can put it on the back. Suggestions?

Secondary thing:

I was thinking about buying a new qctp before I start investing in holders, I was thinking the AXA QCTP.

Is it worth the upgrade on this machine?

-

12-19-2013, 10:17 AM #9

Registered

Registered

- Join Date

- Sep 2012

- Posts

- 323

-

12-19-2013, 12:48 PM #10

Gold Member

Gold Member

- Join Date

- Jun 2004

- Posts

- 6618

-

12-22-2013, 09:16 PM #11

Registered

Registered

- Join Date

- Dec 2013

- Posts

- 41

I upgraded my 8x12 with an AXA size from Phase II. It's the only way to go for manual work but for CNC I'm thinking about gang tooling.

I have turned Thomson 5/8" ball screws on my 8x12 with no annealing but I did chip a couple of inserts on the outer layer and it was slow. I don't think the outer diameter of a budget ball screw can be considered precisely concentric with the bearing surface of the screw. Lots of people have done it anyway with good results so I did not worry much about it.

My 8x12 is not CNC yet so I am watching your thread for ideas. My spindle is converted to a 3 phase motor with VFD which is wonderful. Eventually I would like to get the VFD under CNC control as well.

-

12-22-2013, 10:14 PM #12

Registered

Registered

- Join Date

- Dec 2009

- Posts

- 61

I've been thinking about ganging tooling and I am trying decide how to best do it. My main worry is about the travel as the cross slide does not have alot of room and it would seem like I would have to extend it beyond the edge of the crosslide for it to fit.

I'm also trying to decide whether I should do a horizontal or vertical setup.

I was using a hardinge turret lathe yesterday and I notice how simple its mechnism seemed to be. You pull down the level, that rotates it, pop it back up, that locks it in position, no pneumatics.

-

12-23-2013, 02:53 AM #13

Registered

Registered

- Join Date

- Dec 2013

- Posts

- 41

I checked out a few hardinge turret lathes on youtube and was amazed how productive a manual machine can be. Like this for example.

Hardinge Turret Lathe - YouTube

You could leave the factory cross slide in place with a couple of gang tools on it with cnc and add a hardinge style turret under cnc control for amazing versatility. It would be a big project to make a turret and the short bed on the 8x12 would be a limitation though. As usual, I'm wishing for a slightly bigger machine.

-

12-23-2013, 09:48 AM #14

Member

Member

- Join Date

- May 2008

- Posts

- 1185

looks like his first time!

not

-

12-23-2013, 03:53 PM #15

Gold Member

Gold Member

- Join Date

- Nov 2009

- Posts

- 4415

Glad that turret lathe video was posted. I had never seen 1 in action. They come up for sale on CL all of the time in my area, mostly 3 phase.

Is the rotation automatic? I only see him pulling that lever and the turret seems to spin automatically. It would make a lot of sense in a production environment. After initial sequencing of operations and set up of the tools it seems almost idiot proof. Of course at that point, I would crash it.

-

12-23-2013, 04:24 PM #16

Member

Member

- Join Date

- Apr 2006

- Posts

- 8159

Yes once you pull it back past a certain distance it will auto rotate. The ones I used at work could freewheel too at a point so you could push it back by hand to the previous tool if you are only using 2 tools for example. They had separate depth stops per tool also. Depends on the model.

Hosshttp://www.hossmachine.info - Gosh, you've... really got some nice toys here. - Roy Batty -- http://www.g0704.com - http://www.bf20.com - http://www.g0602.com

-

12-23-2013, 04:39 PM #17

Member

Member

- Join Date

- Apr 2003

- Posts

- 354

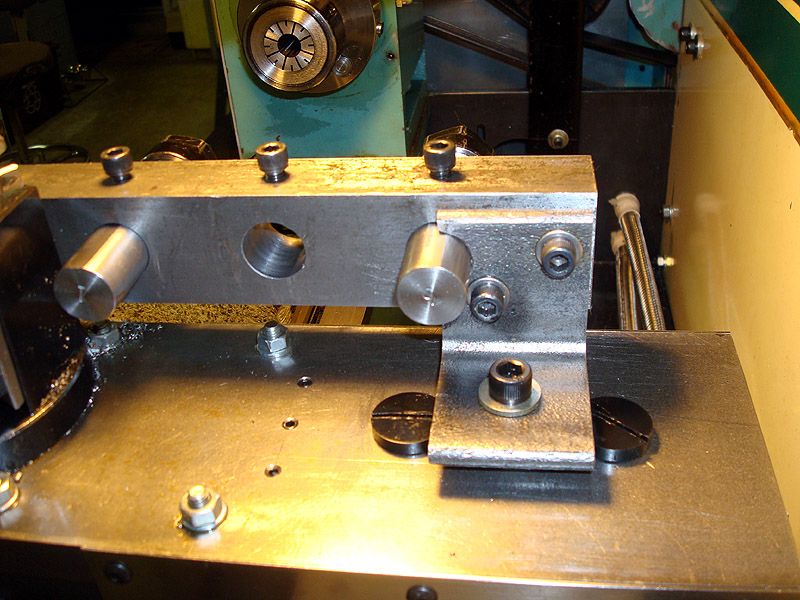

Here's a little gang tool I made for my ORAC (8x16) retrofit project. It has a dovetail to match the wedge style QCTP and can be installed in seconds. I made the ER16 3/4" straight shank collet chucks, the nuts were purchased. The 3/4" holes were bored in-situ so that would be perfectly on center. I chose 3 tools so things wouldn't be too crowded. You do have to be careful and watch out for crashes.

All tool offsets are stored in Mach's tool table and I can switch between any of the 3 gang tools or 8 other QC tool holders with good repeatability. At the very least, a wedge QCTP & dedicated holders is a requirement for CNC lathe work. An ATC would be even better but adds another layer or 2 of complexity to the project. WAY over my head right now!

Oh, I removed the compound and added a bolt-on steel plate to the carriage to mount the QCTP. There's 4 tapped holes on it to allow different positions of the post but so far haven't moved it from the original installation.

edit: forgot the pic of the other end of the toolbar. A bolt-on bracket to firm up the far end. The one 5/16" U.N.F SHCS screws on & off in seconds.

-

12-23-2013, 05:00 PM #18

Gold Member

Gold Member

- Join Date

- Jun 2004

- Posts

- 6618

Mine is similar to this one, but the tools aren't mounted together.

I have updated a little from these pictures to make them more solid mounts for the collet holders, but still basically the same setup.

Instead of the center tool, I now have a 3/16" bit to accommodate another set of bushings I make. Now I can drill two sized holes and turn and part stuff all with the same setup and 3 tools.

Lee

Lee

Similar Threads

-

CNC "KIT" for 8x12 8x14 mini lathe - or cheap/small CNC lathe?

By tinkering in forum Mini LatheReplies: 15Last Post: 05-05-2011, 11:59 PM -

8x12 (8x14) Lathe Mods

By TroyO in forum Mini LatheReplies: 11Last Post: 02-08-2010, 01:21 PM -

Harbor Freight 8x12 / Lathemaster 8x14 Mini-Lathe CNC Conversion

By fignoggle in forum Mini LatheReplies: 1Last Post: 06-04-2009, 05:41 AM -

LM 8x14 or HF 8x12?

By TMaster in forum Mini LatheReplies: 8Last Post: 08-22-2007, 12:05 AM -

Who makes the HF 8x12 and Lathemaster 8x14?

By Tim Wiltse in forum Mini LatheReplies: 5Last Post: 05-24-2007, 05:41 AM

Reply With Quote

Reply With Quote