I sure hope everyone has been too busy making chips on their machines to be hanging out here! It's been really dead here lately. Where is everyone?

Regards,

Ray L.

Thread: Where Is Everyone?

Results 1 to 17 of 17

-

02-08-2014, 07:48 PM #1

Gold Member

Gold Member

- Join Date

- Feb 2006

- Posts

- 7063

Where Is Everyone?

-

02-08-2014, 07:53 PM #2

Registered

Registered

- Join Date

- Jul 2007

- Posts

- 675

Hey Ray. Had to deal with a lot of personal stuff the last 6 months. Hope to be back in the shop this year.

-

02-08-2014, 08:01 PM #3

Gold Member

Gold Member

- Join Date

- Feb 2006

- Posts

- 7063

-

02-08-2014, 09:54 PM #4

Member

Member

- Join Date

- Jun 2013

- Posts

- 416

Waiting on my mill to get in. Also, orders for my routers kicked up so I've been having to devote more time to production.

Nate

Fine Line Automation

www.finelineautomation.comFine Line Automation

www.finelineautomation.com

-

02-09-2014, 07:20 AM #5

Registered

Registered

- Join Date

- Jul 2007

- Posts

- 675

-

02-09-2014, 07:27 AM #6

Gold Member

Gold Member

- Join Date

- Feb 2006

- Posts

- 7063

-

02-09-2014, 03:23 PM #7

Registered

Registered

- Join Date

- Dec 2009

- Posts

- 594

I was waiting to rear more on the ATC, so it's your fault. :argue:

-

02-09-2014, 10:36 PM #8

Gold Member

Gold Member

- Join Date

- Jun 2004

- Posts

- 6618

Making chips yesterday. Plasma cutting today.

Lee

Lee

-

02-10-2014, 05:01 PM #9

Registered

Registered

- Join Date

- Mar 2011

- Posts

- 480

Makin' chips.

Made this bash guard for my mountain bike this weekend.

http://s4.postimg.org/q6uybbhel/bash_guard.jpg

-

02-10-2014, 05:09 PM #10

Gold Member

Gold Member

- Join Date

- Feb 2006

- Posts

- 7063

Nice!

Regards,

Ray L.

-

02-11-2014, 01:27 AM #11

Registered

Registered

- Join Date

- Feb 2011

- Posts

- 605

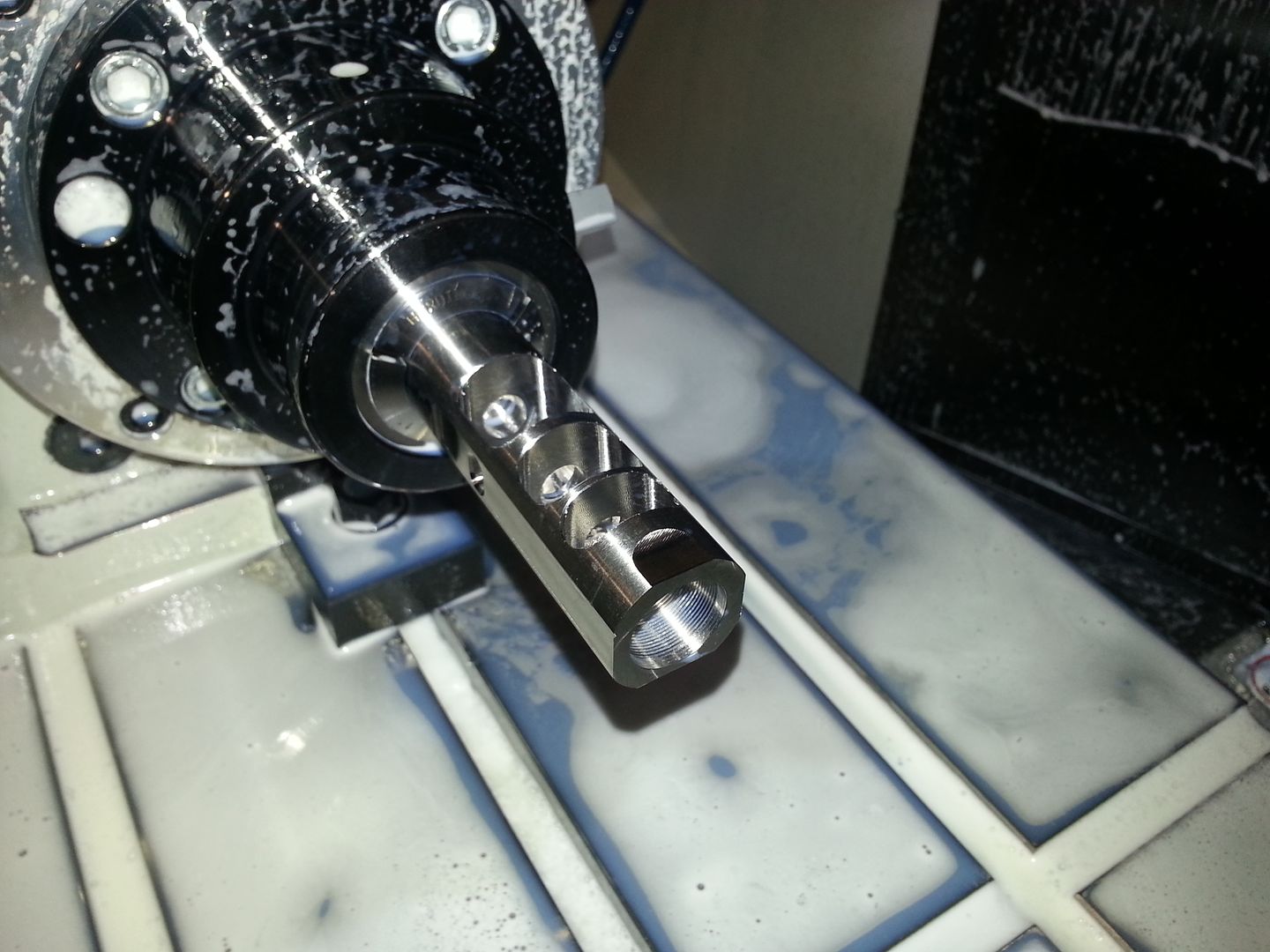

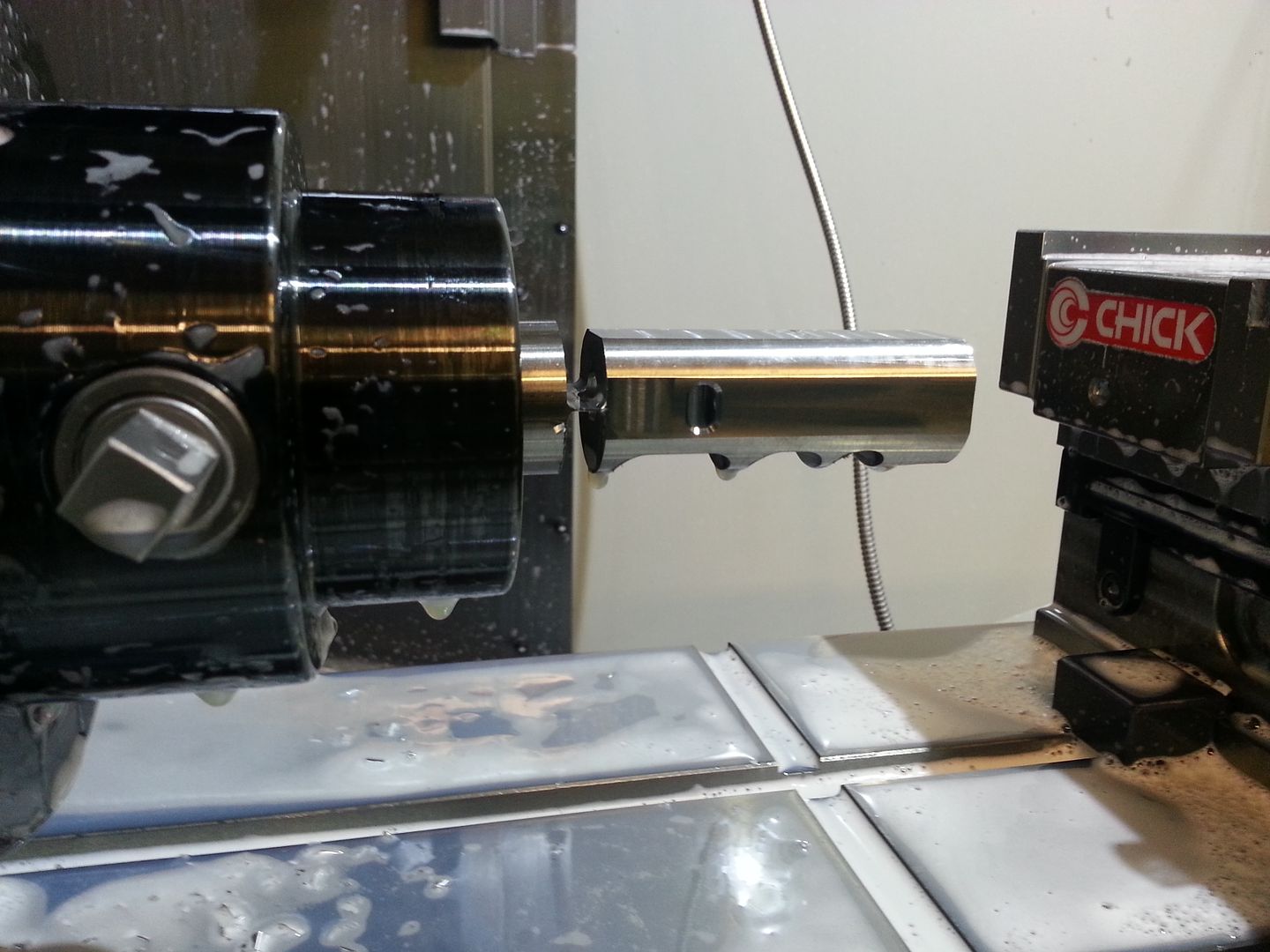

I don't count really. But I was making my first Titanium part. Coming from aluminum and even steel having to run 300 SFM is so slow. Pretty sure I could max out the spindle on the machine at work with a 1/4" tool.

PM-45 CNC conversion built/run/sold.

PM-45 CNC conversion built/run/sold.

-

02-11-2014, 01:34 AM #12

Registered

Registered

- Join Date

- Jan 2014

- Posts

- 36

Nice job jid. The wonders machine can do

For Machinery Relocation, trust only Hanlon & Wright

For Machinery Relocation, trust only Hanlon & Wright

-

02-11-2014, 02:36 AM #13

Registered

Registered

- Join Date

- Oct 2005

- Posts

- 35

Beautiful, what caliber? If I may ask, why titanium?

-

02-11-2014, 02:42 AM #14

Registered

Registered

- Join Date

- Oct 2005

- Posts

- 35

Just learning and watching. Waiting for my fourth axis to arrive and waiting to get the latest version of the bob before moving forward. I've got a lot to learn; tooling is eating up my budget and I've still got to settle on a zeroing method and get the appropriate pieces and parts together to support that. Did i mention that tooling is eating up my budget?

Ain't this fun?

-

02-11-2014, 02:57 AM #15

Registered

Registered

- Join Date

- Feb 2011

- Posts

- 605

Compensator is for a 9mm major, open division race gun. All the typical reasons for Ti: light, strong, doesn't corrode, and is hard to machine.

PM-45 CNC conversion built/run/sold.

-

02-13-2014, 11:36 PM #16

Member

Member

- Join Date

- Jul 2006

- Posts

- 525

That's looking nice, jared! looks like a very well thought out part, too. Its hard to tell, is that a 3d machined variable root radius in the bottom of those pockets?

-

02-15-2014, 03:48 AM #17

Registered

Registered

- Join Date

- Feb 2011

- Posts

- 605

Pockets are drafted and use a surface offset of the OD for the inside walls with some fillets at the joints. So yeah its all 3D surfaced.

PM-45 CNC conversion built/run/sold.

Reply With Quote

Reply With Quote