Hey everyone, I could really use some help with my project.

I'm trying to cut some shapes into formica with my 5x10 home built CNC. They're pretty small and detailed pieces, each one measuring only 2.25" wide and 96" long. The material is called formica, it's used for cabinet facings kind of like a laminate. The material can be found here: Brushed Aluminum

Quick Overview

DecoMetal laminates and solid metals come in lustrous colors that go from cool anthracite to dusky burnished copper in textures that project energy, modernity and a feel for for craftsmanship. Suitable for light duty horizontal or vertical applications: walls, furniture, retail fixtures, signage, exhibits and displays.

Anyways, I tried cutting it using an up cut 1/6" router bit with the good side of the formica facing down. It has a kind of cork or mdf backing on the material with a very thin aluminum face. My problem is that my router bit is pulling up all of the edges, on the back and the front. The back I can just sand down but I can't do the same on the front as I'll ruin the nice finish. I can't sand the edges because they're so small.

My feedrate is 60 ipm, plunging 0.08" (the material is only 0.045" thick) and doing it all in one pass. I don't have a vacuum hold or anything, so I'm just clamping down the material on the table on one side along the length.

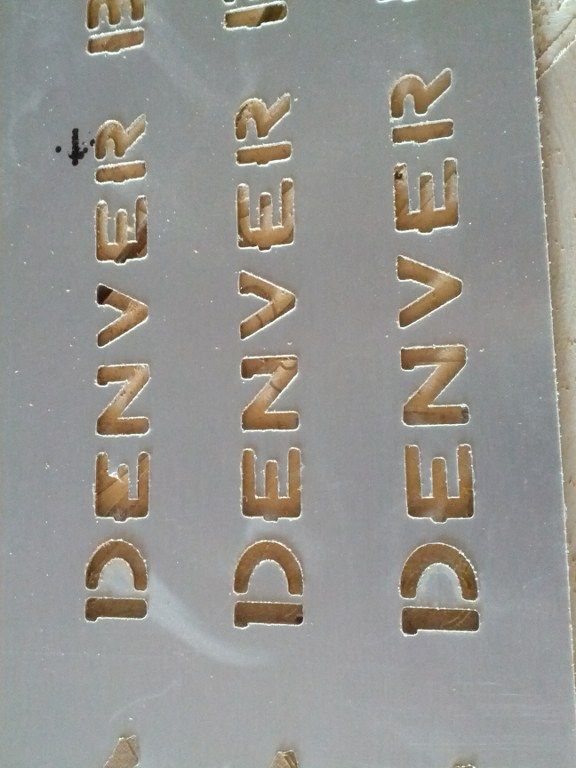

Here's a few pics of my test piece. Each one of these rows is supposed to be cut down into strips. I didn't see the point of cutting them cause they turned out so bad.

On the first pic, even the jaw of the horse on the bottom was broken off from the router bit pulling.

Any help with the different setting to try would be appreciated.

Thread: Routing aluminum formica

Results 1 to 16 of 16

-

07-31-2014, 07:03 AM #1

Registered

Registered

- Join Date

- Mar 2014

- Posts

- 12

Routing aluminum formica

-

07-31-2014, 12:27 PM #2

Community Moderator

Community Moderator

- Join Date

- Mar 2003

- Posts

- 35538

Re: Routing aluminum formica

You'll get much better results with a larger diameter, downcut bit. I'd rough cut everything with a 1/8" downcut, leaving about .01-.02.

Then finish cut with a 1/16" downcut. Climb cut might give a lightly better finish.

I think the only way you'll be able to keep the small details from breaking off is to glue the sheet down to a substrate, and use a solvent to remove the sheet after cutting. When I've done something similar, I'd glue them down with contact cement and use laquer thinner to remove them.Gerry

UCCNC 2017 Screenset

http://www.thecncwoodworker.com/2017.html

Mach3 2010 Screenset

http://www.thecncwoodworker.com/2010.html

JointCAM - CNC Dovetails & Box Joints

http://www.g-forcecnc.com/jointcam.html

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

07-31-2014, 12:32 PM #3

Gold Member

Gold Member

- Join Date

- Jun 2004

- Posts

- 6618

Re: Routing aluminum formica

I can tell you that true laminate or Formica machines very well with standard router bit. Are you using a router as a spindle? What do you estimate is the RPM of the spindle?

From what you have mentioned, you SHOULD be getting better looking cuts. In just about any sort of laminate. I have cut the shiny aluminum Formica before, but it had the typical phenolic resin type backing. It machined the same as the normal stuff.

Hope you find a solution.Lee

-

07-31-2014, 12:55 PM #4

Community Moderator

Community Moderator

- Join Date

- Mar 2003

- Posts

- 35538

Re: Routing aluminum formica

Also, it looks like your bit is dull? Cutting laminate requires very sharp bits, and laminates dull bits very quickly.

Gerry

UCCNC 2017 Screenset

http://www.thecncwoodworker.com/2017.html

Mach3 2010 Screenset

http://www.thecncwoodworker.com/2010.html

JointCAM - CNC Dovetails & Box Joints

http://www.g-forcecnc.com/jointcam.html

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

07-31-2014, 05:24 PM #5

Registered

Registered

- Join Date

- Mar 2014

- Posts

- 12

Re: Routing aluminum formica

Thanks for the responses.

Yes I am using a router as a spindle, a hitatchi 2.1hp router. I believe I had it set at 24k RPM, I had it set at the top speed. Should I slow this down?

I would like to use a 1/8" bit but there are many parts of the piece where this size bit just won't fit.

I may chalk this up to just a dull bit. I have a few more in the mail, downcuts this time and hope it will reduce the break off's since it will be pushing down rather than pulling up.

-

07-31-2014, 05:30 PM #6

Registered

Registered

- Join Date

- Jul 2014

- Posts

- 2

Re: Routing aluminum formica

It would help if your spoil board was flat. When I run that lam. I use ONSRUD 57-040 1/8 down bit. Also I would light glue to table

-

07-31-2014, 05:48 PM #7

Gold Member

Gold Member

- Join Date

- Jun 2004

- Posts

- 6618

Re: Routing aluminum formica

I think you may also try a straight flute cutter. It is what I use on polycarbonate. It is also what we used to flush trim laminate when we made our own counter tops and cabinets. They were all straight flute carbide cutters. Onsrud is a good brand and what I use. The down cuts you have coming may help, but I think they will generate more heat on the material. It that is the case, then flip the material back over so that only the backer gets warm. That way it may leave you with a good clean face cut.

Lee

-

07-31-2014, 05:57 PM #8

Registered

Registered

- Join Date

- Mar 2014

- Posts

- 12

Re: Routing aluminum formica

Do you have a link by any chance of where I could buy the straight bits? I can't seem to find any 1/16" straight single flute bits. TIA.

-

07-31-2014, 06:27 PM #9

Gold Member

Gold Member

- Join Date

- Jun 2004

- Posts

- 6618

Re: Routing aluminum formica

I generally get mine from McMaster Carr, but I don't see the 1/16" ones there either.

My secondary source is here. Holbren.Lee

-

07-31-2014, 06:33 PM #10

Community Moderator

Community Moderator

- Join Date

- Mar 2003

- Posts

- 35538

Re: Routing aluminum formica

A downcut will be better. I've cut a lot of that stuff over the years.

Be aware that small bits will get dull very quickly. Don't run at 24,000, as that will make them dull quicker. Try around 18,000 for a 1/16" bit, and maybe 15,000 for a 1/8" bit.

If you rough it with the 1/8" bit like I said before, the 1/16" bit will last a lot longer. Laminates are very hard on router bits.Gerry

UCCNC 2017 Screenset

http://www.thecncwoodworker.com/2017.html

Mach3 2010 Screenset

http://www.thecncwoodworker.com/2010.html

JointCAM - CNC Dovetails & Box Joints

http://www.g-forcecnc.com/jointcam.html

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

08-01-2014, 06:50 AM #11

Registered

Registered

- Join Date

- Jun 2012

- Posts

- 817

Re: Routing aluminum formica

Most of that looks like it was from pulling loose from the table and resulting chatter. I'd start with a freshly surfaced spoil board sprayed with adhesive and a new sharp straight flute carbide bit. Like ger21 mentions slower RPM's too.

-

08-02-2014, 09:17 PM #12

Registered

Registered

- Join Date

- Jul 2010

- Posts

- 46

Re: Routing aluminum formica

+1 for chatter, since OP mentioned only clamping the material along one edge?

-

08-03-2014, 07:43 PM #13

Registered

Registered

- Join Date

- Mar 2014

- Posts

- 12

Re: Routing aluminum formica

I will clamp down the material more securely next time as well as glue it to my spoil board. I'm hoping that the downcut bit will help as well.

-

08-04-2014, 01:13 AM #14

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 683

Re: Routing aluminum formica

As others have suggested a downcut bit will help greatly. Do a test first with a new downcut bit. measure any chipping you want to eliminate and then divide that width by 2 and make the 2 finish paths at that width.

But another thing I think would help even more is to make your cut through the aluminum first and get it nice and smooth. It looks like the AL ply is .03 or so so make your first depth cut just a few thou thicker. Cut through that then do a step down through the formica.

Good luck.

-

08-14-2014, 07:30 AM #15

Registered

Registered

- Join Date

- Mar 2014

- Posts

- 12

Re: Routing aluminum formica

Thanks for all the help everyone. I was able to get the job done with the 1/16" downcut bit with the 1/8" shank by using an adapter to fit my router. Switching from an upcut to a down cut bit made a huge difference. Nothing was even close to pulling up/out like it did last time. A new, sharp router bit also likely helped the cause. Cuts were clean and smooth.

I bought 2 bits figuring I could have 1 as a backup was a good idea because after installing 1 in the router, I moved the machine around trying to home it and accidentally hit a clamp and broke the first bit before even making a cut. Time to get a few more in case I do the same thing or it starts to dull.

-

08-14-2014, 12:22 PM #16

Registered

Registered

- Join Date

- Apr 2012

- Posts

- 141

Similar Threads

-

Cutting Laminate (like Formica) on a CNC machine

By Mark Lach in forum Fagor AutomationReplies: 0Last Post: 01-17-2014, 03:58 PM -

Routing Aluminum

By mccafferty in forum CNC ToolingReplies: 7Last Post: 02-08-2013, 12:43 AM -

Routing aluminum?

By stealthshooter in forum DIY CNC Router Table MachinesReplies: 33Last Post: 01-07-2013, 08:35 AM -

Routing Aluminum as fast as I can?

By Imperium in forum Material Machining SolutionsReplies: 5Last Post: 10-17-2007, 02:11 PM -

Observations on Routing Aluminum

By musicmkr in forum DIY CNC Router Table MachinesReplies: 7Last Post: 09-14-2005, 04:59 PM

Reply With Quote

Reply With Quote