Still think there is something wrong with the machine. 2500mm/min feed is under 100IPM, that should be no problem, there's plenty of video of Mini Mills cutting at that feedrate and making good parts. What is the depth of cut for the finish pass?

If those are the roughing passes and you haven't done a finish, then yeah you might be pushing it hoping to have usable surface finish after some heavy slotting.

Thread: Poor finish on a Mini Mill SS

Results 21 to 38 of 38

-

01-21-2015, 04:50 PM #21

Registered

Registered

- Join Date

- Feb 2011

- Posts

- 605

Re: Poor finish on a Mini Mill SS

PM-45 CNC conversion built/run/sold.

-

01-21-2015, 06:15 PM #22

Registered

Registered

- Join Date

- Feb 2010

- Posts

- 1184

Re: Poor finish on a Mini Mill SS

Sorry if I missed this fact, but is the machine still under warranty?

-

01-22-2015, 01:11 PM #23

Registered

Registered

- Join Date

- Jun 2010

- Posts

- 60

-

01-22-2015, 01:17 PM #24

Registered

Registered

- Join Date

- Jun 2010

- Posts

- 60

-

01-22-2015, 01:20 PM #25

Registered

Registered

- Join Date

- Jun 2010

- Posts

- 60

Re: Poor finish on a Mini Mill SS

The **** thing is we can't even sell it anymore. Not with good conscience anyway.

We have to fix it.

If only someone knew how

-

01-22-2015, 01:51 PM #26

Registered

Registered

- Join Date

- Feb 2010

- Posts

- 1184

-

01-22-2015, 01:56 PM #27

Registered

Registered

- Join Date

- Jun 2010

- Posts

- 60

-

01-22-2015, 02:49 PM #28

Member

Member

- Join Date

- Jan 2005

- Posts

- 15362

Re: Poor finish on a Mini Mill SS

They should be doing a Vibration Test first, if that is ok, then do the Ball-Bar Test,the Vibration test will tell them if the spindle & spindle motor are within spec, (Bearings Etc) this needs to be the first Test

So you got the machine 4 years ago, was it just sitting all that time doing nothing,& this was the first job you tried on it, in most machine shops it would of payed for itself in that timeMactec54

-

01-22-2015, 03:16 PM #29

Registered

Registered

- Join Date

- Jun 2010

- Posts

- 60

Re: Poor finish on a Mini Mill SS

-

01-22-2015, 06:30 PM #30

Member

Member

- Join Date

- Jan 2005

- Posts

- 15362

Re: Poor finish on a Mini Mill SS

Aquatic

I wonder if the first owner had a crash & damaged the ball screws, anything is possible, Yes I know they said it had never been crashed ! 1500 hrs & you paid how much, thats far from new

When they changed the Motherboard, the machine parameters may not have been installed correctly, this to could cause the problems, you have had also

It's easier for responders, if you tell the whole storey in the first postMactec54

-

01-22-2015, 08:32 PM #31

Registered

Registered

- Join Date

- Feb 2010

- Posts

- 1184

Re: Poor finish on a Mini Mill SS

What was tested to make you say "spindle and head are good" and how?

What did the ballbar test reveal?

-

01-23-2015, 01:57 AM #32

Registered

Registered

- Join Date

- Jun 2010

- Posts

- 60

Re: Poor finish on a Mini Mill SS

There is damage to the rear Y axis cover. But nothing that looks like it could have caused damage to the ball screw. I did ask this question of the technicians and they said all was good. If something had have happened the coupling would have been damaged.

The Haas agents have taken our parameters and compared to factory settings. Spot on.

The price is the going rate for that machine here in Australia. A new MiniMill S2 is just shy of A$100000.00

-

01-23-2015, 02:00 AM #33

Registered

Registered

- Join Date

- Jun 2010

- Posts

- 60

-

01-25-2015, 03:36 PM #34

Registered

Registered

- Join Date

- Sep 2011

- Posts

- 43

Re: Poor finish on a Mini Mill SS

About 15 years ago I bought a new Daewoo VMC 4020. When we took a couple of test cuts on some 6061t6 aluminum we experienced the same thing. I had the Daewoo tech come out and they replaced the spindle cartridge. Tried it again same thing. This time they sent a Daewoo factory representative from New York to look at the machine. He replaced the spindle and same thing. He took at the spindle and they had it dynamically balanced and put it back in. Been fine for the last 15 years.

John

-

01-25-2015, 11:31 PM #35

Registered

Registered

- Join Date

- Jun 2010

- Posts

- 60

Re: Poor finish on a Mini Mill SS

Still no ballbar test. Not sure why no one has pitched yet :-(

-

01-26-2015, 12:40 AM #36

Gold Member

Gold Member

- Join Date

- Feb 2009

- Posts

- 6028

Re: Poor finish on a Mini Mill SS

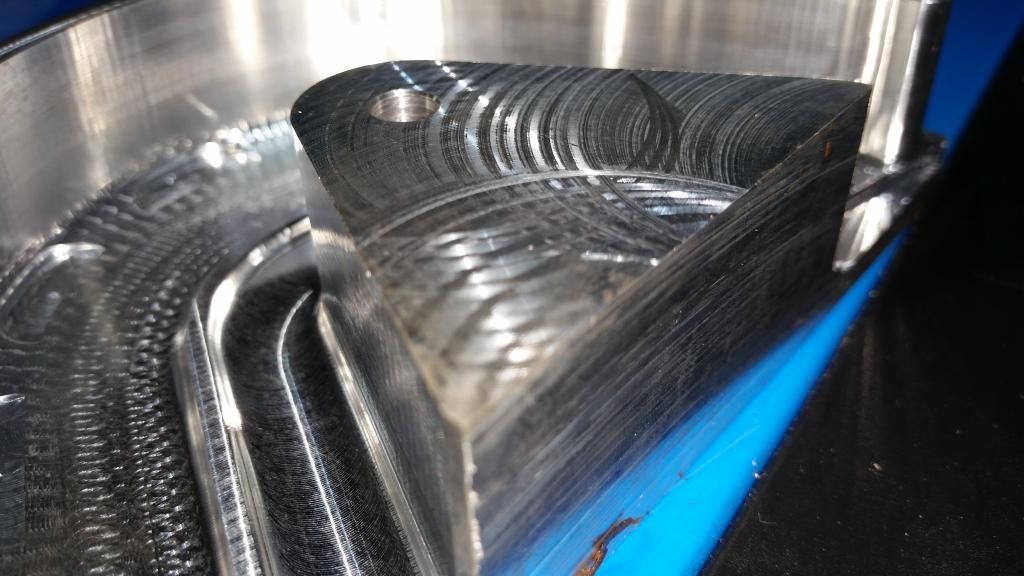

Man, even the top looks horrible. That looks like a loose spindle there.

-

02-13-2015, 11:07 AM #37

Registered

Registered

- Join Date

- Jun 2010

- Posts

- 60

Re: Poor finish on a Mini Mill SS

A bit of an update.

Alfex, local Haas agents have gotten involved and done a whole bunch of tests. 4 visits later. The machine has been level check at every visit. They have admitted that there is definitely something amiss. That in itself is a win for us.

However they have no idea on how to fix it. Packets of data have been sent to Haas USA on 3 occasions now. And still no solution. Seams it has stumped everybody.

What they did today was swap out the Y axis motor and encoder with the std minimill on the premises. The technician did a test on the motor while in it was off the machine and apparently the shudder was very obvious. (I was not there)

While the motor was out the torque on the front mounting bolt was checked. 1/4 turn!!! That's a lot if you ask me.

I got there once it was all back together with the swapped out Y motor and cut a test piece. Not 100% fixed but a huge improvement. The cabinet door no longer rattles when jogging in X and Y.

So more data off the the states tonight. Lets see what they say on Tuesday. Alfex have also offered 2 brand new motors to install and test.

I am a little happier that we have some progress. Until the invoice arrives :-(

-

03-02-2015, 01:39 PM #38

Registered

Registered

- Join Date

- Jun 2010

- Posts

- 60

Re: Poor finish on a Mini Mill SS

My luck has changed! Hopefully 0000

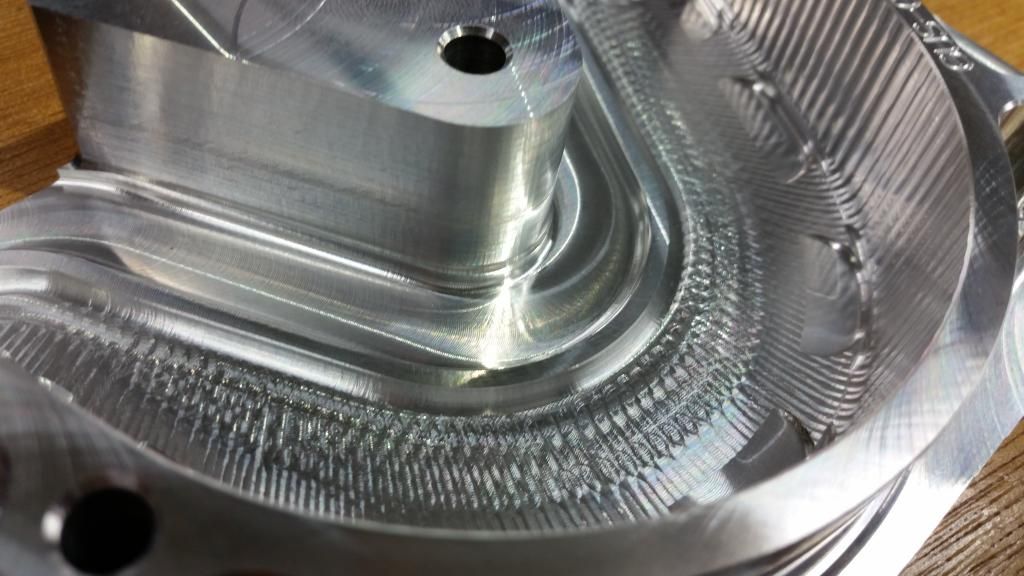

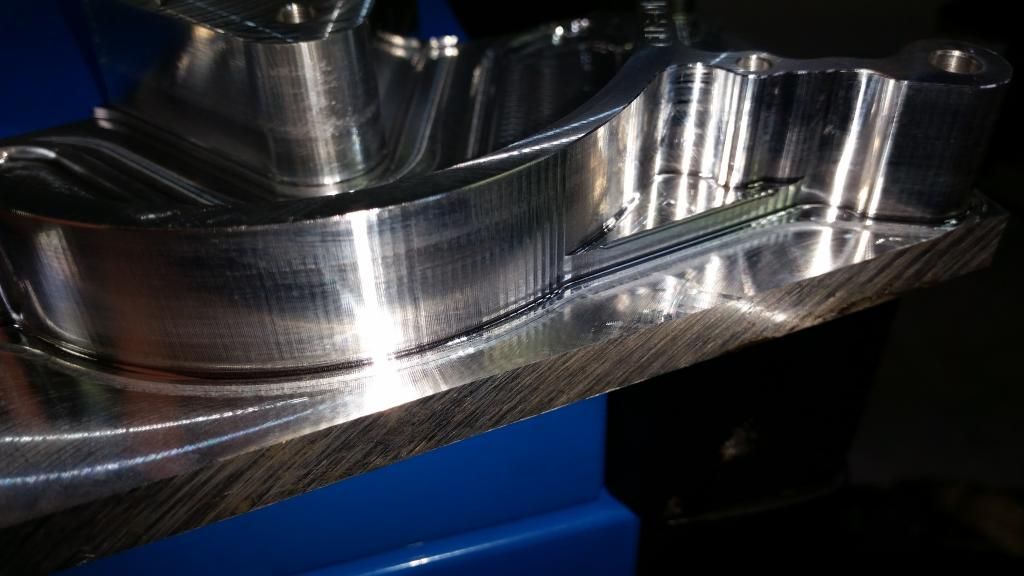

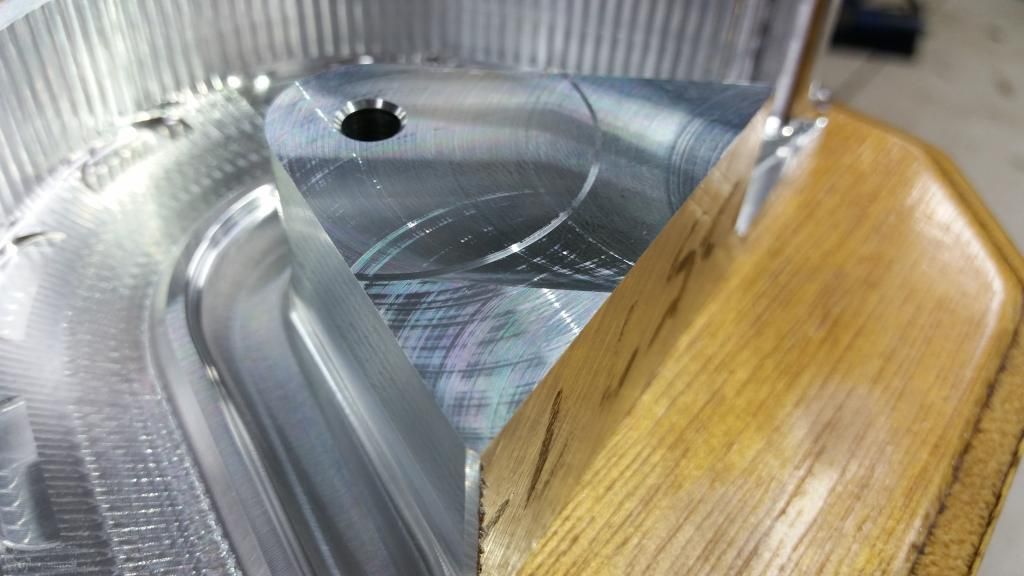

Same machine today top photo, old part 2nd photo.

Day and night

No more dips in Z

No more shudder in XY

Still a slight mark at a change in direction. But I cannot feel it with my fingernail

All I can say on the fix is changes to parameters

303, 750, 753, 884, 885, 886, 900, 901, 902

All have to do with the signal being sent to the motor. The stuff you see on an oscilloscope.

Waiting for the full report from Haas. I will report back once I have this.

Tried to convince the technician that he should not charge us as we have offered our machine up as a fault finding learning opportunity. 0

Don't think he fell for it!

Has to be one of the best Mondays in a LOOOOONG time

Similar Threads

-

Poor Finish on new machine

By J Monty in forum Knee Vertical MillsReplies: 2Last Post: 04-11-2013, 01:23 AM -

Poor quality finish

By NylonAdmiral in forum MetalWork DiscussionReplies: 5Last Post: 04-27-2012, 06:05 PM -

Poor finish

By LLDesigns in forum Benchtop MachinesReplies: 16Last Post: 07-02-2011, 01:56 AM -

poor surface finish

By sinha_nsit in forum CNC ToolingReplies: 3Last Post: 02-17-2010, 04:48 AM -

Poor surface finish

By pmsmichelle in forum MastercamReplies: 2Last Post: 02-05-2010, 03:54 PM

Reply With Quote

Reply With Quote