need to engrave some smallish text in aluminum, like dog tag size...

just looking to see if there are any recommendations on what end mills I should be looking at?

looks like 45,60 and 90 degree tips all seem popular, I don't think I have a preference (well none that I have experience to know about)

I do have the drag engraver, but I was looking for something that would cut deeper...

Results 1 to 19 of 19

-

04-27-2015, 07:52 PM #1

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 297

just looking for some engraving advice...

-

04-27-2015, 10:58 PM #2

Re: just looking for some engraving advice...

I use the cheap carbide single flute cutters from Ebay, they seem to work OK, I usually engrave to .010, but have done .020 with them in aluminum and steel.

edit:

I usually use the 30 degree bits, 5140 rpm, 5 ipm feedrate , with limited spindle speed and single flute cutters, I have found this to be acceptable, although it is slow. i have run as high as 20 ipm with these cutters but the quality is not nearly as good. If it has to look nice I use the cleanup pass in my cam software.mike sr

-

04-28-2015, 01:18 AM #3

Registered

Registered

- Join Date

- May 2006

- Posts

- 168

Re: just looking for some engraving advice...

I have engraved aluminum with the 45 and 60 degree bits. I had cut depths of 0.01" to 0.015 " with the feed rate of 15 to 20 inches per minute.the trick is to not have the aluminum weld itself to the bit. Coolant will help a lot. I use a KoolMist in a spay bottle on the router. WD40 or a fine spray of window cleaner also works works.

-

04-28-2015, 09:21 AM #4

Gold Member

Gold Member

- Join Date

- Jun 2006

- Posts

- 2512

Re: just looking for some engraving advice...

A general guideline is that when engraving text the height of the characters should be not less than 7 times the line width. So if you know the engraving cutter tip width and angle you can determine the depth of cut, or with any two parameters you can calculate the third.. Easiest to draw it in CAD if you have the possibility, otherwise brush up on you trigonometry.

A 30 degree cutter is easily broken and a 60 degree can be to wide for the small stuff, so as is often the case you may have to make a compromise. The cutter are usually, if not always, carbide.

Run the cutter as fast as you can, a strap-on high speed spindle is best, say 30,0000 rpm +. To be safe the feed rate per revolution should be no more than a few percent of the cutter tip width. If you are in a hurry trial and error may be necessary, and expensive. I was unable to find feed rate recommendations on the net.

Phil

-

04-28-2015, 04:23 PM #5

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 297

Re: just looking for some engraving advice...

thanks for all the tips...

one question I have is about this:wouldn't tip width be essentially 0? ie the point is rather pointy/small...percent of the cutter tip width.

or do you determine tip width as the width of the cutter at DOC? or somewhere in the middle?

-

04-28-2015, 04:57 PM #6

-

04-28-2015, 06:00 PM #7

Gold Member

Gold Member

- Join Date

- Jul 2007

- Posts

- 1602

Re: just looking for some engraving advice...

Tip widths are variable. If they are too small they break too easily. Most of the ones I have are in the .005 range but if you buy from a place like BitsBits, you can specify almost any width.

bob

-

05-22-2015, 05:32 PM #8

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 297

Re: just looking for some engraving advice...

so had some time this week to play...

have 2 questions though....

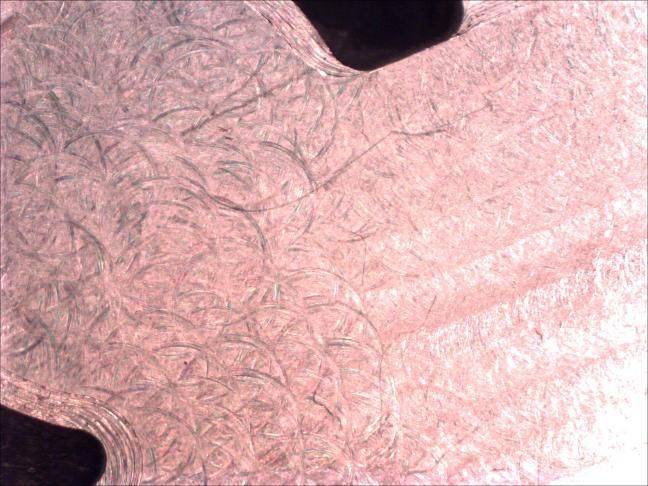

what caused these swirl marks on the edge of my part?

I am guessing my fixture did not hold the ends that well and they flopped/vibrated/not sure what you would call it? just a bit? but I would like some expert opinion...

fwiw that's like a 40x optical mag or so and probably some digital image distortion or some such... it just is not that big in real life... unless you are viewing on a small smart phone or something...

anyway, they will buff out easy enough... just looked weird...

also, was an 1/8" end mill... if that matters...

2nd question... Path Pilot and it's silly 0 radius arc thingy that it complains about.... how do I get it to stop complaining? if it would just ignore those arcs and skip to the next line that would be like a 0.0004" or less error... I can live with that... actually if I wanted that sort of tolerance I would get a different mill...

I love my Tormach, but it just isn't the right tool for keeping less than 0.001 tolerances... I would guess you would need a pretty temp stable ultra ridged mill to do that?

I was using Cambam and the LinuxCNC post... any way to convince cambam to skip them?

-

05-22-2015, 07:17 PM #9

Registered

Registered

- Join Date

- Jan 2005

- Posts

- 111

Re: just looking for some engraving advice...

SomeWhat

How does the LinuxCNC post in CamBam deal with tool changes. Does it just stop the spindle and wait for you to raise the head to make a tool change or does it move the head up also.

Did you change the post to add a G43 call and an H call for tool length offsets.

Dave

-

05-22-2015, 07:38 PM #10

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 297

Re: just looking for some engraving advice...

badly would be the best description... possibly very badly...

not yet... I usually do everything in Sprut...

but for some stuff CamBam is just so fast and simple...like being able to easily do text and simple shapes (cad ish type work without cad) and then do the CAM part all in less time than it takes to even load sprut...

so having just switched to pathpilot, I have not gotten around to fixing the Post yet... had the one for mach all tricked out and custom, but then HDD on my desktop crashed and I never made a backup

-

05-22-2015, 09:25 PM #11

Registered

Registered

- Join Date

- Jan 2005

- Posts

- 111

Re: just looking for some engraving advice...

SomeWhat

When I was running Mach3 on my 770 I too had CamBam working well. I also updated to the latest version of Mach and ran Mach Standard Mill screen set. I hated Tormachs screen set. Now that we are with Path Pilot CamBam does not play well with it using a Mach post. I don't know where Tormach came up with the M998 for the tool change it sure is not a standard M code.

I like CamBam for 2.5D stuff. I like that you can add tabs easily to hold your parts in place when working on thin material that you have to do an out side profile to.

Keep me posted on how you come out tweeking the linexCNC post.

Dave

dmsohlATtdsDOTnet

-

05-23-2015, 02:43 AM #12

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 297

Re: just looking for some engraving advice...

M998 is a standard Mcode... standard as in it is a macro... Mxxx through Myyy are all standard macro's (not sure where xxx starts or yyy ends... but still they are standardish, in a none standard way ") )

as far as cambam Post Processors go, I think I got it... and in the first try (assuming you don't count the minor oops type stuff)...

seems to work... calls m998 for tool changes (when the tool actually changes) and does G43

always turns on/off coolant though.... m8/m9 is hard coded... not sure how to trigger that from within cambam?

min arc length is now 0.0008" (less than 0.0008" it will forget about an arc and just go in a straight line...) not sure if I can go smaller before Path Pilot starts to complain or not... 0.0008 seems pretty small... not sure I will ever bother tweaking or not? but on a operation that Path Pilot complained about 100's of arc's it no longer complains about anything...

Lots of thanks go to P.Fink and Twocik... my butchered CamBam Post processor is based on P.Fink's original mach post, and Twocik for point it out to me... and to CNCZone for being my file backupCode:M09 ( Pocket1 ) M998 ( T6 : 0.125 ) T6 G43 H6 M6 S5100 M3 M08 G0 X-0.2675 Y0.0025 G0 Z0.0625 G0 Z0.125 M09 M5 M30 M998

and not letting post processor files disappear despite evil hard drives that like to crash and burn...

and not letting post processor files disappear despite evil hard drives that like to crash and burn...

its attached foranyone who cares... just remember, there is no guarantee, no warranty, use at your own risk, your mileage may vary, don't eat the yellow snow...

-

05-23-2015, 04:46 AM #13

Registered

Registered

- Join Date

- Jan 2005

- Posts

- 111

Re: just looking for some engraving advice...

Some What

Thanks for attaching the zip file. I downloaded it and CamBam had no trouble with it so far.

Dave

-

05-23-2015, 04:49 AM #14

Registered

Registered

- Join Date

- Jan 2005

- Posts

- 111

Re: just looking for some engraving advice...

Now someone needs to figure out how to use Path Pilot on other machines

Dave

-

05-23-2015, 08:07 PM #15

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 297

Re: just looking for some engraving advice...

no prob...

this thread has kind of wandered off topic a bit from engraving though..

I am sure this thread will be the first place people look when searching for a cambam path pilot post processor

but on the bright side, its always good to keep them guessing...

of course I am not entirely sure who "them" is, or why they need to be kept guessing... but it seems like the sort of thing I am likely to do, so I will just go with it...

anyway, back onto the other slightly off topic, topic, whats up with those swirl marks?

-

05-23-2015, 09:12 PM #16

Registered

Registered

- Join Date

- Jan 2005

- Posts

- 111

Re: just looking for some engraving advice...

I do a lot of machining in alu with 1/8" end mills. I have never looked with a magnifier at the surface finish. I do know when I run a finger over the surface that it is smooth to the touch. The swerlls I do see are uniform. I agree with you that your blanks may have been effected by vibration or moving in some way.

Can you post a photo at 1X to see what it looks like with out magnification.

Dave

-

05-23-2015, 10:03 PM #17

Re: just looking for some engraving advice...

Steel is pretty bad about leaving swirl marks, some aluminum is as well, flood coolant helps with this, the marks are caused by bits of the metal sticking to the cutter cutting edge. I would try varying the rpm, maybe some kind of coated cutter may help. I try to take a super light cut to finish with flood coolant, seems to work for me.

mike sr

-

05-24-2015, 04:56 AM #18

Registered

Registered

- Join Date

- Jun 2006

- Posts

- 340

Re: just looking for some engraving advice...

I purchased a Dremel drill when I had some engraving to do. Milled a mount for it that held the nose and the body securely. But the play and run out in the Dremel's spindle bearings caused significant distortion to the engraving.

I sold the Dremel (for a loss) and bought a Kress, What a difference, and worth the money.

Bevin

-

05-24-2015, 07:13 PM #19

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 297

Re: just looking for some engraving advice...

fwiw I just posted Ver 2 of the cambam post, made a new thread in the path pilot area, figured it probably should have its own thread.

just fixed the final M998 at the end of the program to get the spindle out of the way when done machining...

the m998 was coming after the m30, so the m998 never got called...so I just moved it before the m30, now all should be good...

unless I missed anything else...

Similar Threads

-

New to engraving raised stamps - Any advice?

By Drunken_Master in forum MetalWork DiscussionReplies: 3Last Post: 01-14-2014, 01:14 AM -

Looking for advice to buy Laser Engraving Machine

By Tom Said in forum Laser Engraving / Cutting Machine General TopicsReplies: 6Last Post: 04-01-2013, 05:10 AM -

Advice on Engraving numbers!

By woodenink in forum Laser Engraving / Cutting Machine General TopicsReplies: 5Last Post: 06-12-2012, 01:11 PM -

Engraving Advice Please!

By novacustard in forum Engraving MachinesReplies: 3Last Post: 06-04-2008, 12:27 PM -

Need advice-new to engraving

By bherr in forum Engraving MachinesReplies: 1Last Post: 02-19-2008, 07:04 PM

Reply With Quote

Reply With Quote