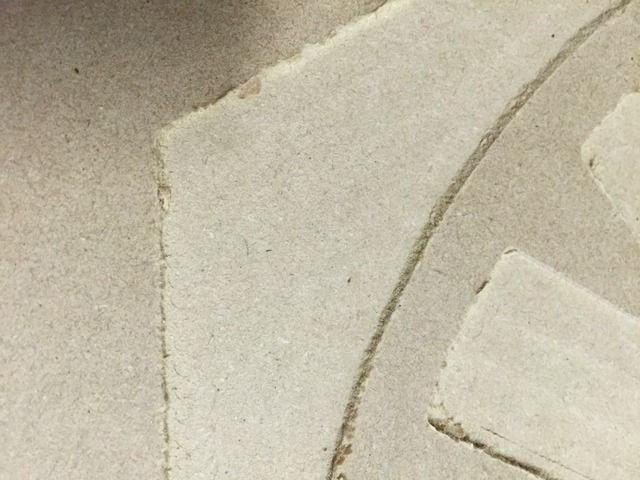

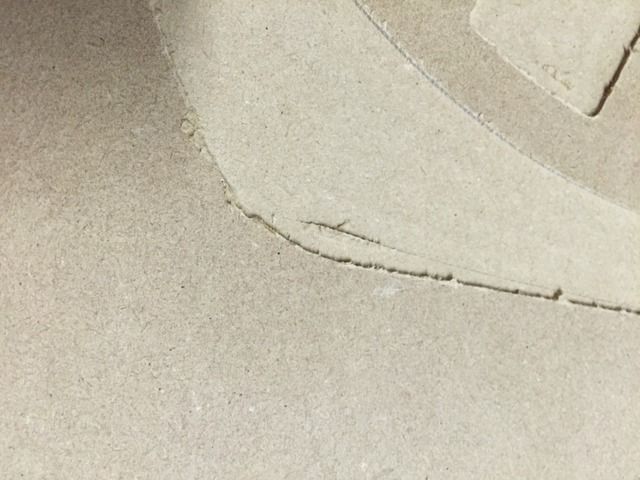

I have discovered an odd occurrence when I was carving today. I am carving a Hexagonal based shape and the corners have different outcomes as seen here. The top picture is correct and the bottom is not. Apologize that I had not sanded first before taking the shots.

The initial job is set to 400ipm at a depth of .0313 and then a second pas at .0625 using an 1/8" end mill. Material is MDF.

I have reviewed the toolpath file in both Aspire and Mach 3 and the anomaly is not there.

I re-ran the file with a single pass at 200ipm at a depth of .07 and the anomaly disappeared. While slowing the job down fixed the issue, shouldn't the machine run at that speed and produce the desired output?

In addition, There is a slight bump in the pocket that is about 1/4" from where the bit stops and goes back as well. This occurred on both runs of the toolpath.

Anybody have some alternate ideas? Is it possible something has worked it's way loose and is causing this? Being able to pick up speed on my jobs was one of the key reasons I upgraded. Like to find a way out of this one.

Thanks,

-Eric

Thread: Carving Anomoly

Results 1 to 19 of 19

Threaded View

-

06-02-2015, 07:37 PM #1

Registered

Registered

- Join Date

- Nov 2011

- Posts

- 73

Carving Anomoly

Similar Threads

-

Surfacing Anomoly

By RHT in forum Uncategorised WoodWorking MachinesReplies: 1Last Post: 04-09-2015, 03:43 PM -

Best bit for v carving

By William McLean in forum WoodWorking TopicsReplies: 6Last Post: 03-01-2011, 09:05 AM -

V23 3D carving

By csmoak25 in forum BobCad-CamReplies: 9Last Post: 04-14-2010, 04:00 AM -

CNC for Ice carving!

By asandoval in forum Community Club HouseReplies: 1Last Post: 03-20-2009, 06:59 PM -

Relief carving small detailed parts - V-carving from greyscale image

By ALAN2525 in forum Uncategorised CAM DiscussionReplies: 16Last Post: 02-12-2007, 12:01 AM

Reply With Quote

Reply With Quote