Hey, guys. Just getting the funds together now to order the little Pro CRP's machine. A few reasons that we are going with the 2x4, but mainly current shop space. We will eventually have the other half of the shop[ insulated and the heated and air conditioned like our current shop. That would mean that we could expand the size of this machine pretty easily if we need to in the future. I do not really see that happening, but who can predict the future?

I am going with the complete kit, plug and play Nema 23 electronics package as well as the new plug and play 2.2 KW 3HP GMT spindle and VFD. That should be a very nice setup.

I will also order the cable track kit, the proximity sensor kit, auto z touch plate kit. I will be running dust collection on this as well. I have a shop made dust collector in my old shop, but we have been using shop vacs in the new shop. We will do away with that noise for this machine and get a small Grizzly wall hanger DC.

Shop our G0710 - 1 HP Wall Hanging Dust Collector at Grizzly.com

I will design and build our own dust shoe for it. This will also have a small vacuum system for it as well.

I have a pump like this one.

Amazon.com: Robinair (15500) VacuMaster Economy Vacuum Pump - 2-Stage, 5 CFM: Automotive

Thread: Ordering Pro 4824

Results 1 to 20 of 136

-

09-17-2015, 04:34 PM #1

Gold Member

Gold Member

- Join Date

- Jun 2004

- Posts

- 6618

Ordering Pro 4824

Lee

-

09-17-2015, 04:50 PM #2

Gold Member

Gold Member

- Join Date

- Jun 2004

- Posts

- 6618

Re: Ordering Pro 4824

I really do not like MDF, so I will probably go with some plastic for the table base. 3/4" star board. Then go with a thinner sacrificial plastic board. The vacuum would be connected to the main table with a mesh of slots. A seal in between it and the top sac sheet. In the top sheet it would have specific holes with o rings installed to hold the parts. Good plan if it works like intended.

The vac table is the only iffy part.Lee

-

09-17-2015, 06:10 PM #3

Registered

Registered

- Join Date

- Jan 2015

- Posts

- 194

Re: Ordering Pro 4824

Congrats! I just ordered a CNCRP Pro 5'x10' yesterday.

Are you sure that vacuum will provide enough CFM and suction for a vacuum table? Most of the DIY vacuums I've seen use the Lighthouse 7123, which has decent suction at fairly high CFM. In talking to a gentleman who recently built his unit, he went with the Lighthouse vacuums with overdrive. When I find out the model, I'll let you know.

Sounds like you're going to have a heck of a machine.

David

-

09-17-2015, 09:42 PM #4

Gold Member

Gold Member

- Join Date

- Jun 2004

- Posts

- 6618

Re: Ordering Pro 4824

I am not sure if it will work or not. It does a good job in an AC system. It won't be running under computer control. It will just be manually operated. We have to insure the vacuum takes before anything else is done.

I plan on getting a portable air tank to go along with it.

It will have 4 zones, each with it's own ball valve. The tank will also have a ball valve and opening that will create an instant vacuum I think.

It will be holding down .22" and .1875" polycarbonate sheets.

Congrats on ordering yours before me.

Take some nice build pictures. Maybe I can cheat over your shoulder a little. Lee

Lee

-

09-18-2015, 01:33 AM #5

Gold Member

Gold Member

- Join Date

- Jun 2004

- Posts

- 6618

Re: Ordering Pro 4824

There are quite a few regenerative pumps on Ebay that won't break the bank if this rotary vane pump does not work.

In fact, to run this one, I would need a really good filter system and it would need oil added often. They are high maintenance. So, instead, I think I will just plan to get one of the regen type. The smaller ones are rated for 27 cfm, which is quite a bit more than the 5 cfm rating on the rotary vane. It may not even need an air tank.

Ahh and the regen type pumps from Gast are maint. free.Lee

-

09-18-2015, 06:47 AM #6

Member

Member

- Join Date

- Feb 2005

- Posts

- 829

Re: Ordering Pro 4824

Leeway, Congrats on the new machine order.

I think I met you once, are you in the Salem Oregon area?

-

09-18-2015, 01:03 PM #7

Gold Member

Gold Member

- Join Date

- Jun 2004

- Posts

- 6618

Re: Ordering Pro 4824

South Alabama.

I have not ever been to Oregon. One of the few States I have not had the pleasure of seeing. Washington, Alaska and Hawaii are the others.

I am finalizing the order with CRP's today. I also ordered a regenerative vacuum pump. It's a Gast and is 1/2 HP model. 42 CFM. It should really suck.

Lee

-

09-18-2015, 04:43 PM #8

Community Moderator

Community Moderator

- Join Date

- Mar 2003

- Posts

- 35538

Re: Ordering Pro 4824

What are you doing with the gast pump? I don't think it's going to suck as much as you think. (Or will it suck more than you'd like?)

If you're using fixtures, it probably doesn't pull enough inches of Mercury.

If you plan on sucking through MDF, then it probably doesn't have enough CFM.Gerry

UCCNC 2017 Screenset

http://www.thecncwoodworker.com/2017.html

Mach3 2010 Screenset

http://www.thecncwoodworker.com/2010.html

JointCAM - CNC Dovetails & Box Joints

http://www.g-forcecnc.com/jointcam.html

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

09-18-2015, 04:53 PM #9

Gold Member

Gold Member

- Join Date

- Jun 2004

- Posts

- 6618

Re: Ordering Pro 4824

No. Not through MDF.

I haven't decided yet on the table base that the vac lines will be connected to, but it will have 4 zones. Each surrounded by rubber seals. Then the sacrificial board on top will have several specific holes that are all located under our parts. Each of those holes will be surrounded by an O ring. I may have to go with more flexible seals than that, but those are all on hand already. I am sure some testing will be in order. I will continue to update the progress here. Lee

Lee

-

09-19-2015, 12:04 AM #10

Gold Member

Gold Member

- Join Date

- Jun 2004

- Posts

- 6618

Re: Ordering Pro 4824

Really the only thing the vac pump will have to do is assist the edge clamps to hold down the center of the sheet. I have been using straight flute Onsrud cutters because they do not tend to lift the material. I would get nice looking cuts with a spiral upcut bit. It does tend to lift the material, but if this vacuum pump can hold it down, we will be golden. We will be using two fixture boards. One for the sides of the guards and another to cut out the tops where the dust ports get welded on.

Ahren sent me an order confirmation earlier today, so we are on track.Lee

-

09-19-2015, 12:34 AM #11

Gold Member

Gold Member

- Join Date

- Jun 2004

- Posts

- 6618

Re: Ordering Pro 4824

I checked out what some of the guys have been doing with the vacuum motors. They are using them in setups on full sheets and they will have vacuum loss in the though cuts. They need all that extra CFM to maintain a good pull while some of the air is pulling through. I won't be faced with those same issues. I will not have any vacuum loss. If the system is tight enough, I could pull the vacuum and turn the valves and pump off. If it is sealed, it would not leak. Big if's there though. This is also why I went with this type pump over a vacuum motor. I am trying to reduce the shop noise somewhat.

Those guys have certainly designed an built some nice vacuum systems though. I saw one with 4 of those motors in it. Wow! Lee

Lee

-

09-19-2015, 12:38 AM #12

Gold Member

Gold Member

- Join Date

- Jun 2004

- Posts

- 6618

Re: Ordering Pro 4824

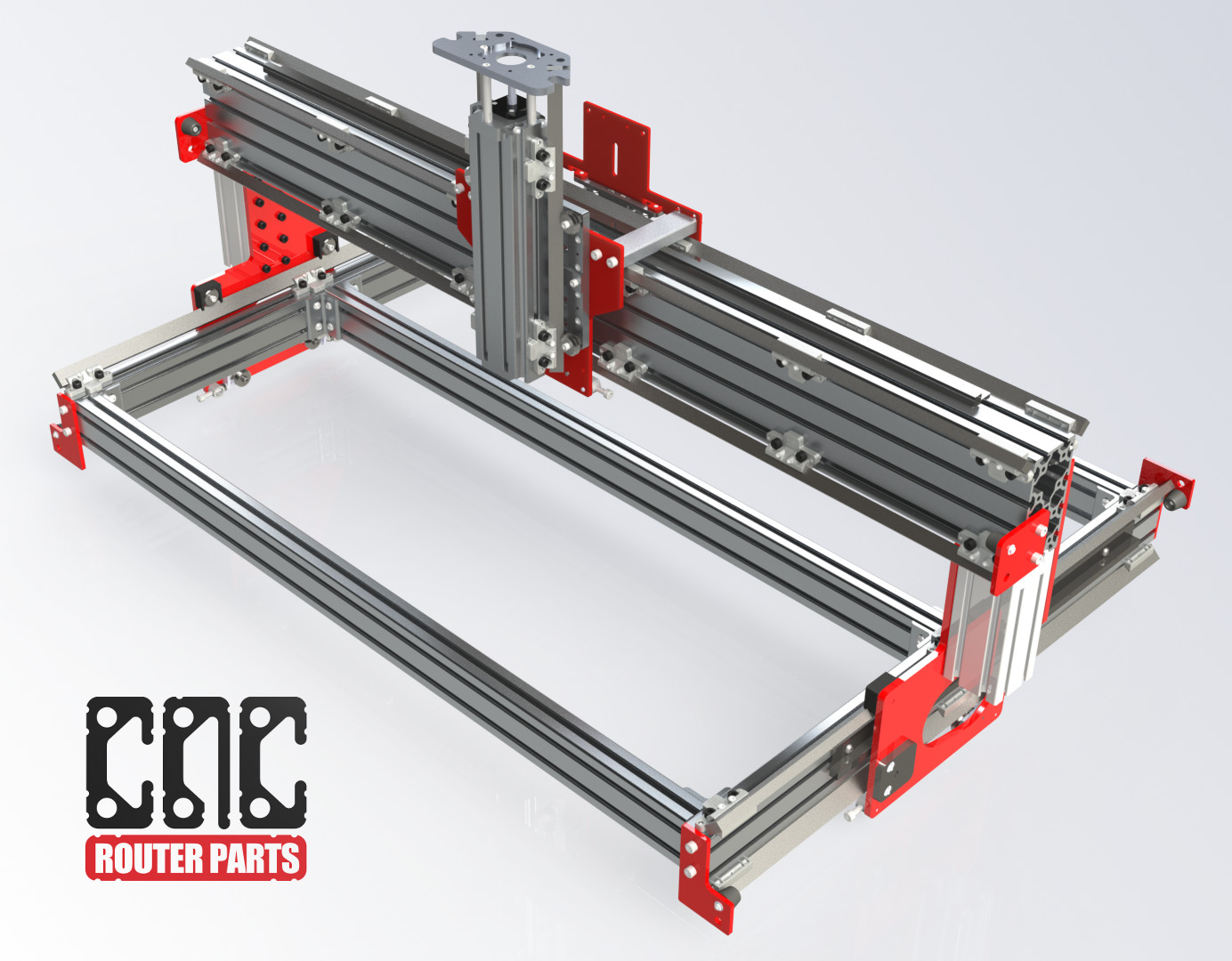

Time for an image of the machine in this thread.

Lee

Lee

-

09-19-2015, 12:39 AM #13

Registered

Registered

- Join Date

- Jan 2015

- Posts

- 194

-

09-19-2015, 02:31 PM #14

Gold Member

Gold Member

- Join Date

- Jun 2004

- Posts

- 6618

Re: Ordering Pro 4824

I forgot to mention that I still have my 4' x 4' plasma cutter that also uses a die grinder as a spindle. We have recently been cutting our tops out with it. I will have it should I need anything larger than 1/4 sheet size. It used the first CRP's system of carriages and drives. It works great too. Recently I was having an issue with the A axis on it keep in time with the X. A Gecko G540 is running it. I found that a pin in the A axis was getting toasted. I slightly bent that pin in the cable to make better contact and so far it has been working. I did order a spare cable and a new Leadshine MX4660 4-Axis Stepper Driver for it as a spare when the G540 fails again. It is a heavier duty drive. I think the G540 would do much easier duty on a router where cutting speeds are lower. Cutting speed and rapids in the plasma cutter are pretty quick on some material.

Lee

-

09-21-2015, 12:08 AM #15

Gold Member

Gold Member

- Join Date

- Jun 2004

- Posts

- 6618

Re: Ordering Pro 4824

Are there any actual CAD drawings of this machine? I saw the PDF note at CRP's, but I would like to know the actual base dimensions of outside edge of the 80/20 to the outside edge in both length and width. I haven't asked CRP's about it. I don't want to slow them down.

I am considering going with sealed baltic birch plywood for the table base and use similar for each fixture. It will have some PVC flanges mounted on the underside. The Starboard or HDPE board I used on my other router is okay, however it is still prone to a little warpage over time. Not quite sure why. It also doesn't hold screws quite as well. Then it costs quite a bit more. Probably close to double the cost of Baltic Birch. I will never buy any MDF or MDF products, so that is out. Way too much humidity down here even in a shop with AC.

I may also need to add a couple cross braces under the table. Maybe not. I will have to see how that will work stock first. Easy enough to add those later should I need them.

I did not order a leg kit, though I will have to put this up on short legs of some type. I am redoing our office here with oak desks that have a granite top. My current desk is one I made years ago out of reclaimed oak flooring and an oak panel door for the legs. That is what this router will sit on initially.Lee

-

09-21-2015, 03:20 AM #16

Member

Member

- Join Date

- Feb 2005

- Posts

- 829

Re: Ordering Pro 4824

PRO4824 - 4' x 2' CNC Machine Plans | CNCRouterParts

On that page are Solidworks Edrawing files. You can download those and use this: https://www.solidworks.com/sw/suppor...nloadcheck.htm

And with that you c an get dimensions of any part of the machine.

-

09-21-2015, 11:12 AM #17

Gold Member

Gold Member

- Join Date

- Jun 2004

- Posts

- 6618

Re: Ordering Pro 4824

Ahh. Thanks for that. I do have Solid Works, but do not have it installed. Turbocad would not open it. Edrawings did fine.

Lee

-

09-30-2015, 11:25 AM #18

Gold Member

Gold Member

- Join Date

- Jun 2004

- Posts

- 6618

Re: Ordering Pro 4824

I received the aluminum extrusions yesterday. Drop shipped from 80/20.

The rest of the order also shipped out from CRP's yesterday. This was faster than I really expected. I am scrambling to make room. Lee

Lee

-

09-30-2015, 02:00 PM #19

Registered

Registered

- Join Date

- Apr 2015

- Posts

- 82

Re: Ordering Pro 4824

i too was surprised by the speed everything showed up. i thought i would have everything ready when it arrived, but instead all the router parts and extrusions sat in my 3 season porch for a few days while i built the table.

-

09-30-2015, 02:05 PM #20

Gold Member

Gold Member

- Join Date

- Jun 2004

- Posts

- 6618

Re: Ordering Pro 4824

The table this will sit on is currently my desk. I do have it's replacement ready to be installed. I guess this weekend is as good a time as any. I must admit that I have been severely procrastinating that. LOML should be happy to get that completed too. Her desk is also in the new installation.

Lee

Lee

Similar Threads

-

New 4824 build here

By Carol in AZ in forum Avid CNCReplies: 0Last Post: 07-19-2015, 02:43 PM -

A2100 Touch screen not working - Lagun 4824 Center

By mccshop in forum Cincinnati CNCReplies: 1Last Post: 07-18-2014, 04:22 AM -

Pro 4824 with the shakes

By kaetamer in forum Avid CNCReplies: 5Last Post: 05-29-2014, 04:17 AM -

CRP 2448 PRO (not a 4824)

By kjk2002 in forum Avid CNCReplies: 27Last Post: 03-18-2014, 08:57 AM -

Pro 4824 Z axis cable track too short?

By kaetamer in forum Avid CNCReplies: 1Last Post: 01-05-2014, 12:39 AM

Reply With Quote

Reply With Quote