I am trying to create a counter bore on a half moon shape (on the curve side) & the problem I am having is that I need the hole to be perpendicular to the flat edge. The only result I can get is the c-bore following the curve. Is there an easy way to adjust this? Thanks, Tom

Results 1 to 13 of 13

-

12-13-2006, 05:41 AM #1

Registered

Registered

- Join Date

- Aug 2005

- Posts

- 70

creating a straight c-bore on a curved surface

-

12-13-2006, 09:34 AM #2

Registered

Registered

- Join Date

- Dec 2006

- Posts

- 68

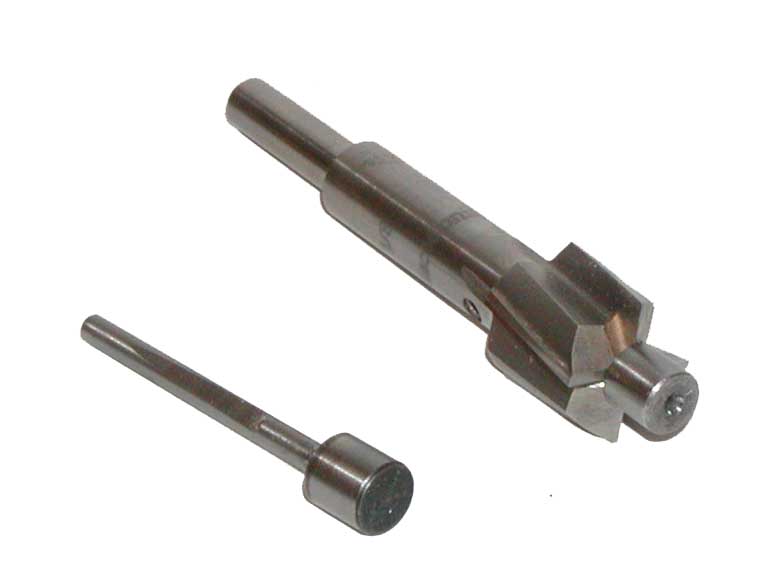

If you are using a drill press then a tool thats sits in the first hole and acts as a guide will help:

You could make one of these out of a drill bit if you knew what you were doing.

If you are on a machine that's a bit more solid then an end mill, slot drill or even a small boring bar could do it. What machine are you using and what material is being cut?

-

12-13-2006, 02:10 PM #3

Monkeywrench Technician

Monkeywrench Technician

- Join Date

- Jan 2004

- Posts

- 3154

Make or use a plane/face that is parallel to the bottom face of the counterbore, draw a circle, extrude out of the part.

Remove the .txt to use the samplewww.integratedmechanical.ca

-

12-13-2006, 08:22 PM #4

Registered

Registered

- Join Date

- Aug 2005

- Posts

- 70

DareBee,

I attached some files of what I am trying to do. I can't seem to get the c-bore straight but a plain through hole works ok. Thanks for the help.

-

12-13-2006, 08:41 PM #5

Registered

Registered

- Join Date

- Jul 2005

- Posts

- 450

There are probably other ways of doing this, but here is how i would do it:

1) create a reference plane parallel to the flat face, that intersects the point you want the cbore at.

2) create a sketch on that plane, and add a point for the cbore location

3) in hole wizard select the sketch point as the hole location, hole should be in the right direction then.

4) you may need to also extrude a cylindrical cut outwards from the plane to remove material above the cbore.

-

12-14-2006, 07:25 AM #6

Registered

Registered

- Join Date

- Aug 2005

- Posts

- 70

Thanks for the help guys. What I did was sketch a circle on the flat surface the same dia. as the bore then extruded it just above the curved surface. This left a nice little boss or protrusion on the surface. I then had a flat area to insert the counter bore on. It worked perfectly. The new file is the bumper zip. Thanks again, Tom

-

12-14-2006, 02:32 PM #7

Monkeywrench Technician

Monkeywrench Technician

- Join Date

- Jan 2004

- Posts

- 3154

I am not sure what sort of "zip" files you are attaching but I am not getting any of them to work.

Is it not a step quicker to do it like my sample?

Although your way will allow the use of the hole wizard if you feel that it is necessary to do so.www.integratedmechanical.ca

-

12-14-2006, 03:59 PM #8

Registered

Registered

- Join Date

- Jul 2005

- Posts

- 450

DareBee, i didnt mean to imply that my way of doing things is better, its just how i do it (mainly because im lazy, so i rely on the hole wizard for calculating the cbore fit). Your way is quicker, i just like to have wizard generated holes.

On a technical note its a shame solidworks hole wizard doesnt give the option to do an extruded cut above each cbore the size of the screw, as you always need the clearance to insert the screw into the cbore, and it would remove a step.

-

12-14-2006, 06:05 PM #9

Registered

Registered

- Join Date

- Aug 2005

- Posts

- 70

DareBee,

The files are just simple j-pegs, nothing fancy. I had to get this project done no matter how I did it. Deadalus just happened to give me an idea to try & it worked. Now that it is done I will go back & try your sample. I think the neat thing is you guys both gave me a different way to accomplish the same task. It is always good to know a few extra tricks.

-

12-14-2006, 09:04 PM #10

Monkeywrench Technician

Monkeywrench Technician

- Join Date

- Jan 2004

- Posts

- 3154

daedalus

I didn't take any implications from you and if I came across as ornery I am sorry.

IMO there is no wrong way to get right results.

I figured out the attachments after I deleted the new zip program I was trying. If I can't figure out how to use a simple zip program it must be no good. LOL. Back to winzip for me.www.integratedmechanical.ca

-

02-13-2007, 05:27 PM #11

Registered

Registered

- Join Date

- Aug 2006

- Posts

- 259

off topic, but darebee, winrar is also a good zip program.. works just the same as winzip but better imo

-

02-13-2007, 08:20 PM #12

Monkeywrench Technician

Monkeywrench Technician

- Join Date

- Jan 2004

- Posts

- 3154

RAR is fine, I don't like it though.

WinZip is too bloated and fluffy.www.integratedmechanical.ca

-

02-14-2007, 07:58 AM #13

Registered

Registered

- Join Date

- Sep 2006

- Posts

- 7

why dont we just sketch the shape and use revolve cut ..after that copy where ever it is necessary..if we have lot a instances it may be complicated ...may be

Reply With Quote

Reply With Quote