First of all I would like to say Thanks to all of the members of this site. I've been here for less than a week, and have absorbed a lot of information. What was very confusing to this newbie, is now learned.

To begin:

After browsing one of the more insirational threads on Benchtop mill conversions:

jl123's Original Thread

I have started to plan out my own conversion. I felt it was necessary to summarize much of the knowledge of that thread and go with a few minor revisions I'll be looking to incorporate. Hopefully this can be a source of knowledge for others as well.

I am going to first start out by sourcing the best places to acquire the Mill and conversion parts. I'm looking for some comments and advice from the community along the way. From what I've seen, I like and want to make a few changes to what member jl123 went with his mill. I am mostly going to take a less costly approach.

I'd first like to start by citing the machine: The SIEG X3

X3 at GRIZZLY

It seems to the one of the best candidates for CNC Milling modification out there. $1050 Cost, Stats, and a rigid frame make it the best choice I've seen so far.

So next would be the conversion to CNC parts. CNC Fusion, from what I've found has had the best and most complete offerings of other companies. I've found the prices to be pretty reasonable as well.

CNCFusion

Here is where my first deviation may occur:

I'm looking to use the screws that came with the machine. What sort of drawbacks can I expect to see if I do this?

I gather that ballscrews are a 2/3 addition in quality and ease of movement, but they are also $379 dollars more to go ahead with the ballscrews with the oversized pre-loaded ballnuts.

So if I was to get the cnc conversion kit without the ballscrews, It would cost $299

I may upgrade later, but for now, the regular threads will do fine I imagine (again, I don't want to go broke on limited funds)

Next would be to plan out the size of the 2x NEMA 23 Stepper motors for the x&y axis and 1x NEMA 34 motor for the z-axis.

It looks like these can be aquired on e-bay for about $54 each. for about $170 overall cost.

What is the best in/oz to get for these kits? 280 in/oz for the x&y and then 453 in/oz for the z?

Next you consider the stepper motor drivers and controller software. First of all, I plan to set up a Windows2000 computer to run mach3 for the controller. This costs $159 for MACH3, and I already have a spare computer to use.

ARTSOFT MACH3

I am then planning to purchase 3 new GECKO G203V Stepper motor drivers. These cost $147 each for a total of $441

GECKODRIVES

I would next like to purchase a breakout board to split out the parallel cable to connect to the GECKO drives. Model PMDX-122

Buffered Bi-Directional Breakout Board

with "Charge Pump"

These run about $15 from another source

Breakout Boards

Wow :drowning: already I'm at $2134. Hopefully I can keep the project down to under $2500.

Well, this is all for now. I will return to discuss cabling and connections, power supply, and housing the electrical components.

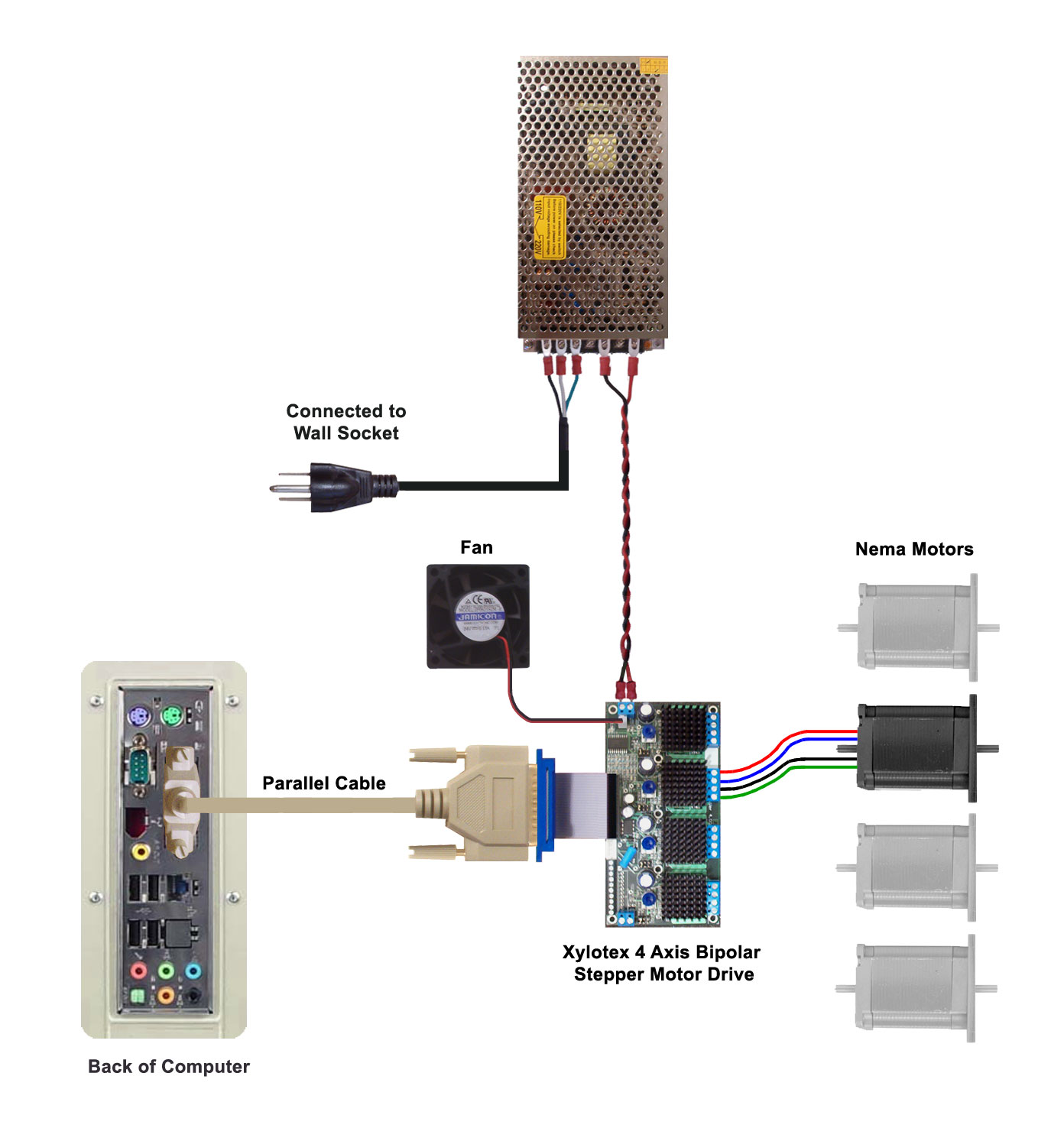

I will also consider using the Xylotex 3-axis kits Xylotex Kits

I hear the geckos are more of a robust package, but perhaps by using the Xylotex, I can cut down on some costs. What do you think?

Any of your comments on the above I would greatly appreciate.

I have highlighted in bold what I am most concerned about....

Thanks Again!

-Brandon

Results 1 to 20 of 25

-

02-04-2007, 09:13 AM #1

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 61

SIEG X3 Budget DIY CNC Conversion Ongoing Project Summary

SIEG X3 Budget DIY CNC Conversion Ongoing Project Summary

-

02-04-2007, 06:05 PM #2

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 357

I did a custom conversion on my x3 with a slant towards keeping it on a budget. http://www.cnczone.com/forums/showthread.php?t=24983 Since that thread I have a made few changes. Performance has been outstanding and table backlash has held well under .001" backlash even on a jogged .001" direction change. You will want stronger steppers than 280oz for the x&y axis if you plan on retaining the acme screws. I am using a Xylotex setup with 425oz Nema 23 steppers on all 4 axis. No lost steps and rapids of 100IPM are possible although I keep them at 70IPM. I kept the large acme screw on the z axis as I feel the trade off in holding power vs speed is worth it. Rapid of 20IPM. I spin the rotary table direct drive/Oldham coupler at 720' min. The head will need to counterbalanced with a strut or pulley system. Check into MACH3 a bit as I think it is only designed to run on XP but I am not sure. My total cost of the conversion was probably around 1100$ but I did not buy any conversion kits. Just raw materials needed for the conversion and a complete 4 axis drive system from Xylotex. I do not use a breakout board.I use mechanical micro switches for limits. I already had Mach3 so that is not included in the conversion cost. Good luck! Steve

-

02-04-2007, 07:58 PM #3

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 61

I'm going to check out your thread. I think I missed it in my search earlier. I will look into the stepper motor requirements further. From jl123's thread I have read a user posting about how the CNCFusion guy had used something like a 160 in/oz motor for the y, a 200 in/oz motor for the x, and something else for the z axis with no problems. This was with the typical threads on the machine.

I had read on artsoft's site that mach3 runs on both winXP and 2000 > Check out their site on the first paragraph

I want to use Win2000 to keep the resource usage lower on my older model PC

As for using counterweights, I think Investing in the Gas spring from CNCFusion for $79 would be a good idea instead of a bulky counterweight system (I'd probably spend just as much rigging something like that up myself) Gas Spring

I'm thinking about using this sort of setup to build my power supply on the Cambell Designs Website: Campbell Designs

-

02-04-2007, 09:41 PM #4

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 61

As I am reading further, I find that to get one of these up and running correctly, you must use homing and limit switches.

I understand that Homeing switches will allow the user to set the cnc back to an origin position (0,0,0) like a cartesian coordinate system.

I also understand limit switches to enable a user to command the machine to not go past any limits of the machine and start cutting past the travel of the axes of the table. This allows for the allowable material limits, and also so the machine doesn't cut into the table.

I am curious as to what switches to use. Like a brand or product to use.

Also, where do you mount the homing switches on the machine?

I feel that I wont bother with limit switches since the software like mach and mastercam can have the limits proggramed into them.

I have seen that Xylotex has some good drawings on where to pin out the wiring on their boards.

Thank you,

Brandon

-

02-04-2007, 09:54 PM #5

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 61

I am really starting to lean towards the Xylotex kits to use for the motor controllers and have a kit with all the required stepper motors.

However, I will need to contact them about perhaps getting a kit with two NEMA 23 280 in/oz X,Y steppers, and one NEMA 34 424 in/oz stepper motors.

I notice they have no such NEMA 34 motor, so perhaps this will be a problem.

The cost of this xylotex kit with free shipping plus also getting a nema 34 424 in/oz from e-bay will cost $345 for the kit, and $54 for the motor.

I will also sell the one NEMA 23 I dont need for $54 on ebay to recoup the costs.

Xylotex 3-axis 280 in/oz kit

Using the Xylotex drives and motors will save $211 over going the gecko route. I will also be eliminating the need to build a power supply I think, saving even more.

I figure the Xylotex are good from what I hear. Some reccomend using Gecko, and I also see good results from using Xylotex.

Using the xylotex kit would also eliminate the need to aquire the parts and build my own power supply for the motors, correct?

Does anybody have some extra experience with the Xylotex products they could share?

Is there also any advantage to using a control drive to command the DC spindle motor? This way the machine can make automatic RPM adjustments. I would probably need to purchase a gecko brush motor drive. any comments on this are appreciated!

Thanks!

-

02-04-2007, 10:30 PM #6

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 61

I was reading in your thread, and see that using NEMA 34 isn't something to do with the xylotex boards!

this is a little disconcerting to find out, if CNC fusion makes a motor mount for the z-axis that is only NEMA 34.

am I wrong here about using the Xylotex for NEMA 34? Where do you think I should go from here?

Perhaps using the CNC Fusion kit is a little expensive for just some motor mounts. Any luck creating the mounts for yourself?

-

02-04-2007, 11:09 PM #7

Registered

Registered

- Join Date

- May 2006

- Posts

- 1469

Brandon I fitted limit switches to my X3 and don't use them. So I agree with you here.

The soft limits in Mach work very effectively on this style of machine.

Of course you need homing for soft limits to work. Soft limits rely on machine coordinates being correct which only happens after "reference all" (homing)

The only thing is that on some conversions I have seen the physical or hard stops are either not there or inadequate.

See this post to see what I mean

http://www.cnczone.com/forums/showpo...2&postcount=24

-

02-04-2007, 11:21 PM #8

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 61

-

02-05-2007, 04:13 AM #9

Registered

Registered

- Join Date

- Jun 2005

- Posts

- 866

The Xylotex drives will work fine. My mill is zipping around nicely with only 260oz-in motors on X and Y. I got one of those 425oz-in motors from Keling for my Z axis. I find myself being forced to get very low decel rates for moving the head down. Once that thing is moving at 60IPM, it does not want to stop. BUt in fairness, I don't have a gas strut mounted yet. I just ordered a 75lb gas strut from McMaster. That should more or less balance it all out. I believe the head is about 80 pounds.

One thing I should specify though. If you use the stock leadscrews, I do not think you will be able to get away with a Xylotex. Rolled ballscrews like those sold by CNCfusion are 3x as efficient. You will save money by using ballscrews, as you will be able to get 23 frame motors and the Xylotex instead of GEcko drives and beefier motors. Also, backlash will be consistent.

So figure 1k for the mill. 549 for the ballscrew X3 kit from CNCfusion. 475 for a Xylotex kit, plug and play.

Honestly, I think 549 is a lot of money for the CNC hardware you get. You would be able to spend probably under 150 if you did all the machining yourself. THis gives you a chance to get familiar with the machines capabilities by using it manually anyways. The 5/8-.2 ballscrew is cheap

-

02-05-2007, 04:38 AM #10

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 61

I have been interested in machining my own motor mounts, but am also unsure of what it really requires as far as the dimensions, and if any of those mounting dimensions are critical to the operation of the stepper motors.

Perhaps it would be easier to have the machine in front of me, but as of now I don't have that convenience.

Does it only matter to get the motor mounts concentric with the ballscrews to the Stepper motors? And then a nice flush mount with some allen screws with the existing X3 hardware? I suppose the tapped holes already exist on the X3 handwheels to bolt up to the motor mounts?

-

02-05-2007, 07:00 PM #11

Registered

Registered

- Join Date

- Jun 2005

- Posts

- 866

I kept the original dimensions of the old hardware as much as possible. This is most critical for height of center of ballscrew to base (dictated by the ballnut mount). So yes, you do need keep everything accurate and flush. I used the original, accurately tapped holes, to mount all of my hardware. I had to make new bearing blocks, ballnut mounts, motor mounts, basically everything except for the Z axis. When I drilled the mounting holes, I drilled them about .01" oversized. This allows for "wiggle room". So I can get it perfectly aligned, tightened down, and some mildly flavored loctite to hold it all together.

I don't think I payed even 50 dollars in material to get it all together. I used angular contact bearings, which I preloaded. This is really the best solution, which the CNCfusion kit does not incorporate. Doing it yourself would allow you to buy the ballscrews, the nice drivers, etc.

Theres another kit out there one out there, which looks pretty nice:

http://cnckits.com.au/

-

02-06-2007, 06:58 AM #12

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 357

The xylotex kit works pretty good. I don't think anybody will say it is as good as the Gecko's though. But I have had pretty good luck with it on my x3 and x2. I did not use limit or home switches on my x2. I just used soft limits in MACH3 and tried to be careful. But sooner or later you will crash and wish you had them. All it takes is a bad glitch or missed steps and then the mill is not doing what MACH commanded and wham you have just smashed something while MACH thinks it is still operating within the soft limits. Trust me it happens. Not a big deal on a little x2 but the bigger x3 can do some nice damage if the table runs away from you at 70IPM. Course you won't be going anywhere near that fast if you choose to keep the acme screws. I do have limit switches on my x3. They share limit and Homing functions. I am just using cheap mechanical micro switches. Easy to hookup directly. Here is a great link showing exactly how to wire them in to a xylotex system- http://www.solsylva.com/cnc/xylotexdrive.html http://www.solsylva.com/cnc/limits.html

Everything you see in my thread I machined myself. The motor mounts were by far the easiest thing to machine. The preloaded dual ball nuts and bearing design was the tricky part as I had a goal in mind of well under .001" table backlash. And so far both table axis have held at or below .0005". But it wasn't easy and there was a lot of initial trial and error to get it to hold that tolerance over time. StevePerhaps using the CNC Fusion kit is a little expensive for just some motor mounts. Any luck creating the mounts for yourself?

-

03-03-2007, 04:48 PM #13

hey guys, sorry i dropped off the map for a while, its been a busy couple months.. ok so i'm back to looking for a small mill, and after reading all of the above, im looking at an x3 either from grizly or hf, whichever i can get a better price.. and then doing the conversion to cnc myself... my questions is this, am i seeing this right, mach 3 is now $150??? last time i looked it was more like $500!!! is there something that i'm missing??? or has the price really come down that much, and by waiting, i've scored?

Grizzly X3, CNC Fusion Ballscrew kit, 3 500oz-in bipolar steppers, 3 203v Gecko's, Linear power supply from Hubbard CNC, Mach 3, BOBcad Pro Art V22, Rhino.

-

03-03-2007, 05:57 PM #14

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 61

there are a few places you can get MACH3 for even cheaper when you bundle it with their stepper motors and drives.

I'm strongly considering ordering from KelingCNC

They sell it for $139

-

03-03-2007, 06:59 PM #15

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 424

-

03-04-2007, 05:11 AM #16

still, for $150 im gonna go ahead and get it, cause i'm afraid it'll go up, i dont have a machine yet.. but i do have the motors, and one of my driver boards built and working... i seriously need to get a machine up and running as soon as i can, but being on a super tight budjet, i may have to go with a tiny machine rather than the x3 types till i can get more money together... i know i should get a bigger machine, but 99% of what im gonna be making will fit in a 3"x3"x3" work area...at least for now... if i can get that going and make a few $$ with this and my new powdercoating setup.. maby i can afford a bigger better machine down the road...

suggestions on a cheaper route to go than the x3?Grizzly X3, CNC Fusion Ballscrew kit, 3 500oz-in bipolar steppers, 3 203v Gecko's, Linear power supply from Hubbard CNC, Mach 3, BOBcad Pro Art V22, Rhino.

-

03-04-2007, 05:45 AM #17

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 61

x2 x1

-

03-04-2007, 02:54 PM #18

Registered

Registered

- Join Date

- Jun 2005

- Posts

- 866

You could skimp on the size of the mill, but I highly recommend not doing that. You are better off saving up slowly and being happier with what you buy, it's cheaper in the long run. That 1% of the time that it won't fit on a smaller mill's work space might make you think a larger mill is worth it...too late.

-

03-04-2007, 03:57 PM #19

yea, i can totally understand that... i'm actually thinking about hitting the family up for "investments" in my business... i got a birthday comming up.. maby i can score some early cash towards that...

i really think that the x3 would be the cats meow for me.. but i may have to go with the x2, just depends on how much of an investment i can get outta my family... most all my family is into building things, so i can offer my services in exchange for the contribution.. if i have it thier gonna want me to make this and that for them anyway, i might as well get them to pitch in and help me get it in the first place...Grizzly X3, CNC Fusion Ballscrew kit, 3 500oz-in bipolar steppers, 3 203v Gecko's, Linear power supply from Hubbard CNC, Mach 3, BOBcad Pro Art V22, Rhino.

-

03-04-2007, 05:55 PM #20

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 61

Similar Threads

-

Sieg X3 Milling Machine CNC Conversion Project

By Bird_E in forum Vertical Mill, Lathe Project LogReplies: 21Last Post: 11-30-2009, 05:31 PM -

Help! What is Sieg X1, X2, X3?

By cjchands in forum Benchtop MachinesReplies: 4Last Post: 10-12-2006, 11:20 AM -

prazi mill cnc conversion, ongoing education

By drwc in forum Benchtop MachinesReplies: 0Last Post: 06-08-2006, 01:53 AM -

K2CNC Summary

By Cutloose in forum K2CNCReplies: 54Last Post: 03-18-2006, 06:09 PM -

Sieg X2 cnc kit at LMS

By KDN Tool in forum News AnnouncementsReplies: 0Last Post: 11-18-2005, 09:46 PM

Reply With Quote

Reply With Quote