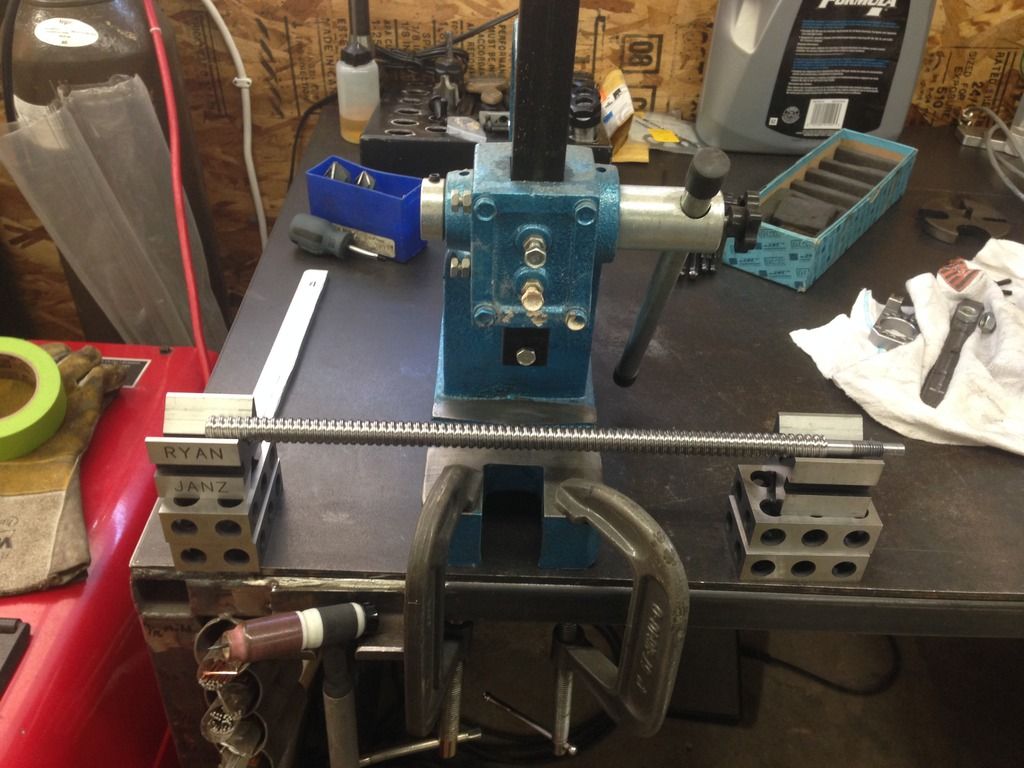

Hey guys, I was hoping I could get your opinion on a few small issues I am having before I carry on with the conversion. I managed to get the controller and mach3 to play nice and got some movement out of the Y axis of the mill. I am using Hoss's stage 3 plans, and with everything installed for the y-axis, I am getting a bit of "wobble" in the ball screw. When I set it up, I tightened the front bearing block assembly first, with the ball nut holder somewhat loose. Then cycled the ball screw back and forth a few times to try and help align itself. Then I tightened down both set screws that hold the ball nut mount in place.

I have two issues:

1. This is the best I could get the ball screw, but it still has a bit of wobble or misalignment to it. When the saddle gets close to the bearing mount block you can here the ball-screw actually hitting the bore at the opposite end. Is there a better method of trying to align the ball screw then what I am currently doing? I'm assuming the current alignment is not acceptable.

2. It also seems to me that this ball screw is pretty noisy. If you listen carefully in the video, I can hear the ball bearings moving around in the ball-nut, is this normal ? Its definitely louder then I expected. I had to repack the balls in this nut because the mandrel I made to remove the shaft failed and so all the balls came out. I divided the balls up (Aprox. 100 total) evenly and put half in each of the nuts.

Anyways, any comments or suggestions would be greatly appreciated.

Results 1 to 6 of 6

-

01-07-2017, 07:27 AM #1

Registered

Registered

- Join Date

- Apr 2015

- Posts

- 72

G0704 CNC Conversion - Ball Screw "wobble"

-

01-07-2017, 03:16 PM #2

Registered

Registered

- Join Date

- Nov 2011

- Posts

- 205

Re: G0704 CNC Conversion - Ball Screw "wobble"

Go back and forth tightening them a couple of times.

If you could use an anti gravity hot air balloon to lift the outer end it would solve the alignment problem.

Otherwise it is bent.

Don

-

01-07-2017, 03:33 PM #3

Registered

Registered

- Join Date

- Jan 2005

- Posts

- 1943

Re: G0704 CNC Conversion - Ball Screw "wobble"

There is a slight bend in the screw. Take the screw out and roll it on a granite plate and you can find the bend. To straighten, jut use a couple vee blocks in a drill press to push the bend out. It isn't that hard to do.

-

01-07-2017, 07:18 PM #4

Registered

Registered

- Join Date

- Apr 2015

- Posts

- 72

Re: G0704 CNC Conversion - Ball Screw "wobble"

Ill pull it out today and have a quick look on my welding bench. Its about as flat as I can get until I get it to work on Monday to check it on the granite surface table. I'm a bit disappointed that this is a problem, I really shouldn't have to try and straighten a precision ground ball screw.

-

01-07-2017, 09:45 PM #5

Gold Member

Gold Member

- Join Date

- Aug 2010

- Posts

- 630

-

01-07-2017, 10:46 PM #6

Registered

Registered

- Join Date

- Apr 2015

- Posts

- 72

Re: G0704 CNC Conversion - Ball Screw "wobble"

I agree there is a large difference, but regardless, its still a huge pain in the ass and in my opinion shouldn't have been an issue in the first place.

I checked the ball screw and it was in fact bent. I used a small arbor press I had in the shop and managed to get it straight-ish. Its definitely better than what it was, but not perfect.

I also took apart the ball nut again, checked and re-packed it and made sure when I was assembling it, that a ball didn't get stuck between the circuits. Its still a bit noisy by my standards, but I'm going to leave it and try it as it is.

Similar Threads

-

Mounting Ball screw with one fixed end and one "semi fixed" end to improve rigidity?

By lazy_mosquito in forum Linear and Rotary MotionReplies: 4Last Post: 09-18-2013, 04:38 AM -

X Axis "Goes Off Pattern", "Awry", "Skewed", "Travels"

By DaDaDaddio in forum Laser Engraving / Cutting Machine General TopicsReplies: 1Last Post: 05-06-2013, 09:59 AM -

95" ball-screw replacement! Help.

By diyengineer in forum Want To Buy...Need help!Replies: 1Last Post: 09-05-2010, 10:26 PM -

BattleAxe "aka" Ball and Chain "aka" the wife.

By ZipSnipe in forum Community Club HouseReplies: 48Last Post: 05-18-2008, 03:53 PM -

Preloading 5/8" thomson ball screw

By TommyB in forum DIY CNC Router Table MachinesReplies: 1Last Post: 12-06-2004, 04:29 PM

Reply With Quote

Reply With Quote