Hey folks!

Been a long-time fan of this forum, and I have learned a ton browsing through the various sub-forums, and researching all the knowledge that this group provides. I rebuild custom, vintage motorcycles and always have the need to make quick, custom parts for the builds (mostly in aluminum). To fill this need, awhile back I built a small CNC router, based on parts and open source designs from OpenBuilds. I got bit by the bug bad, and while the parts I was able to make were satisfying and functional, the limitations of the machine (and open source cloud-based software) pushed me toward researching a larger, more rigid machine. I briefly flirted with the idea of a tormach, but the price felt expensive for a work area that's somewhat limiting for the type of parts I wanted to make. Also, I wanted to keep the footprint of the machine fairly compact.

So after a massive amount of research over the course of a year, I found myself returning often to a machine built by a member here (@katran) named Gabriel. He built a meticulous machine based on aluminum profile and aluminum tooling plate. While nowhere near as rigid and heavy as commercial machines, it fit my footprint needs, and seemed to check the boxes of cutting area, and rigid enough to wok on the small aluminum parts and plate that I most often work with. I can't thank Gabriel enough for detailing his build. I did change a few things in my own design, but I hope that he subscribes to " imitation is the greatest form of flattery," because this build owes a lot to his vision.

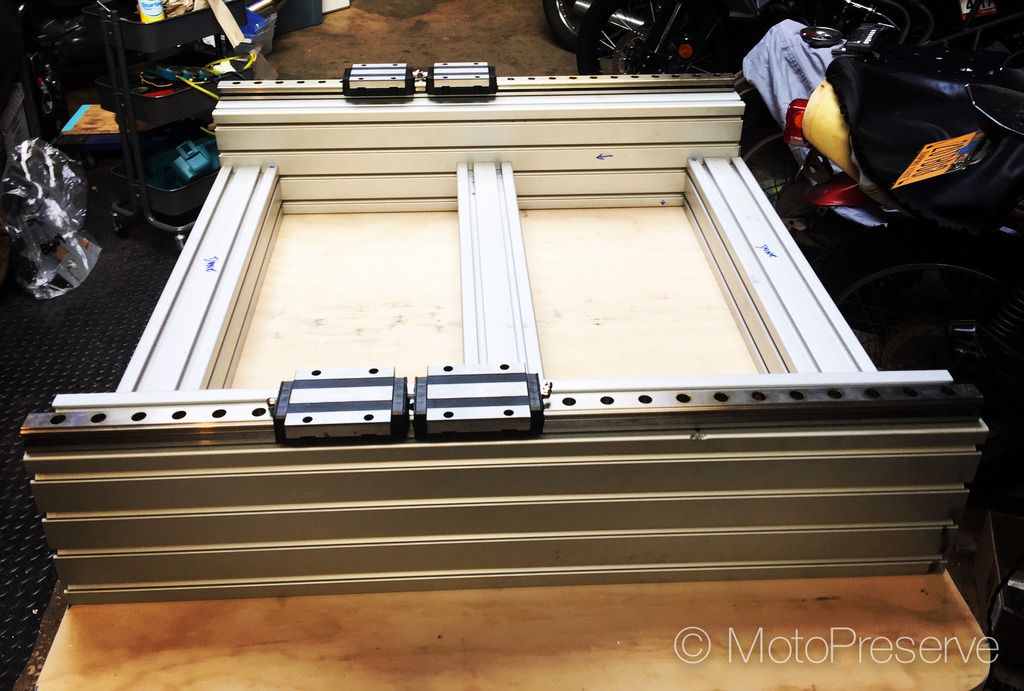

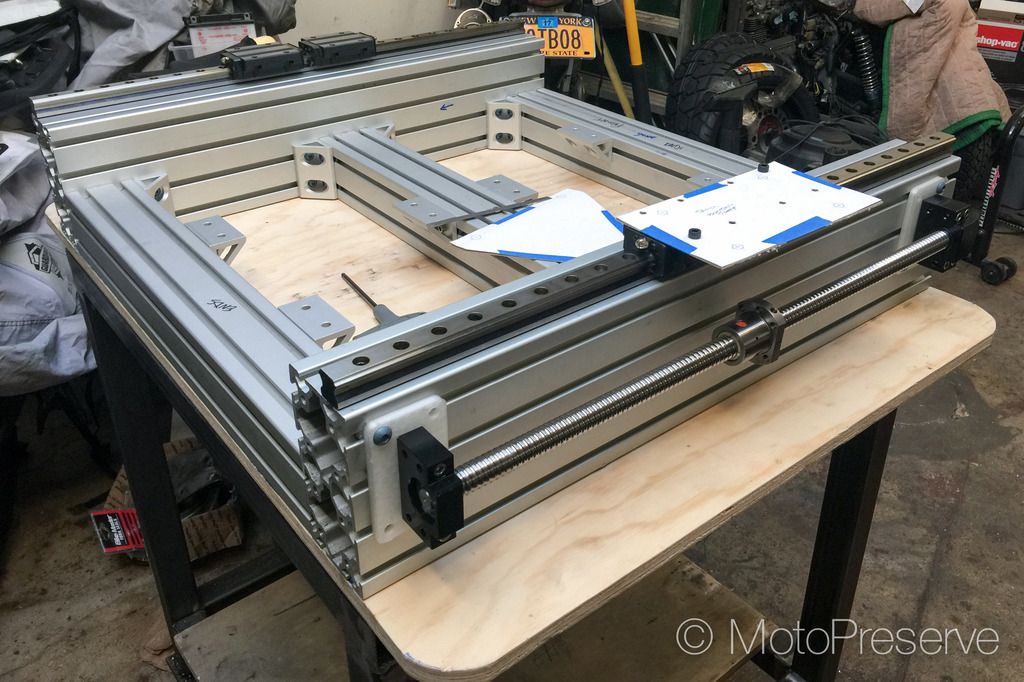

In addition to the aluminum profile and tooling plate, I went with Chinese ballscrews (dual drive on the longer axis), THK linear rails and trucks patiently purchased used on eBay (2 rails/4 trucks per axis), a Chinese water cooled spindle, Mach3 and Nema 23/600 oz size motors.

I never started a thread while I was designing and building it - but I thought I'd post up, since I am now making chips, having a ball and already producing parts from this new machine. Below is a photo of the CNC once I began initial testing - although I have added some features and will be continuing to improve in areas that I find lacking. More photos are included as attachments. Thanks for all the inspiration! Hope you enjoy...

Scott

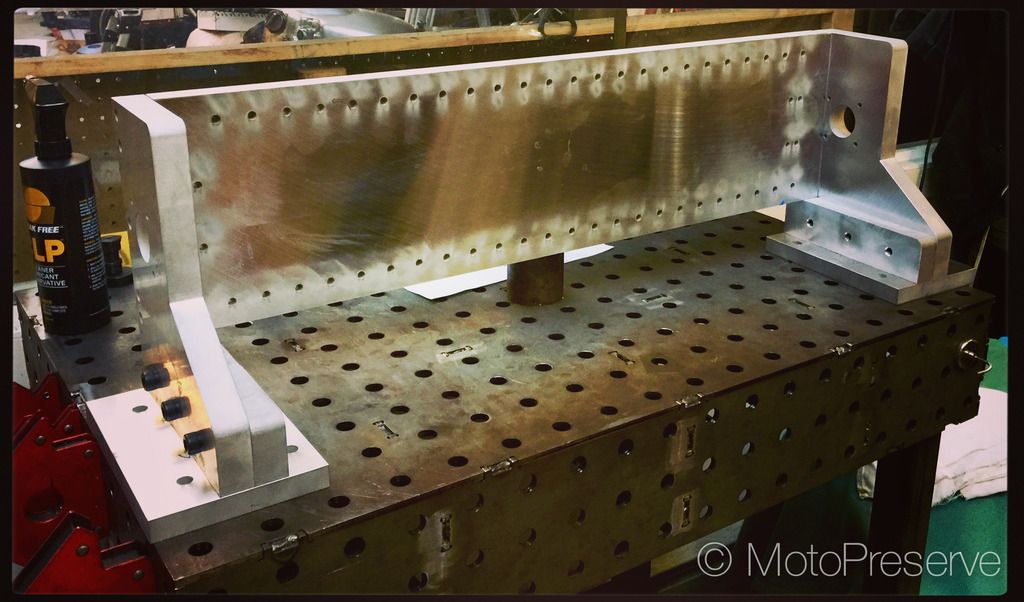

Frame coming together...

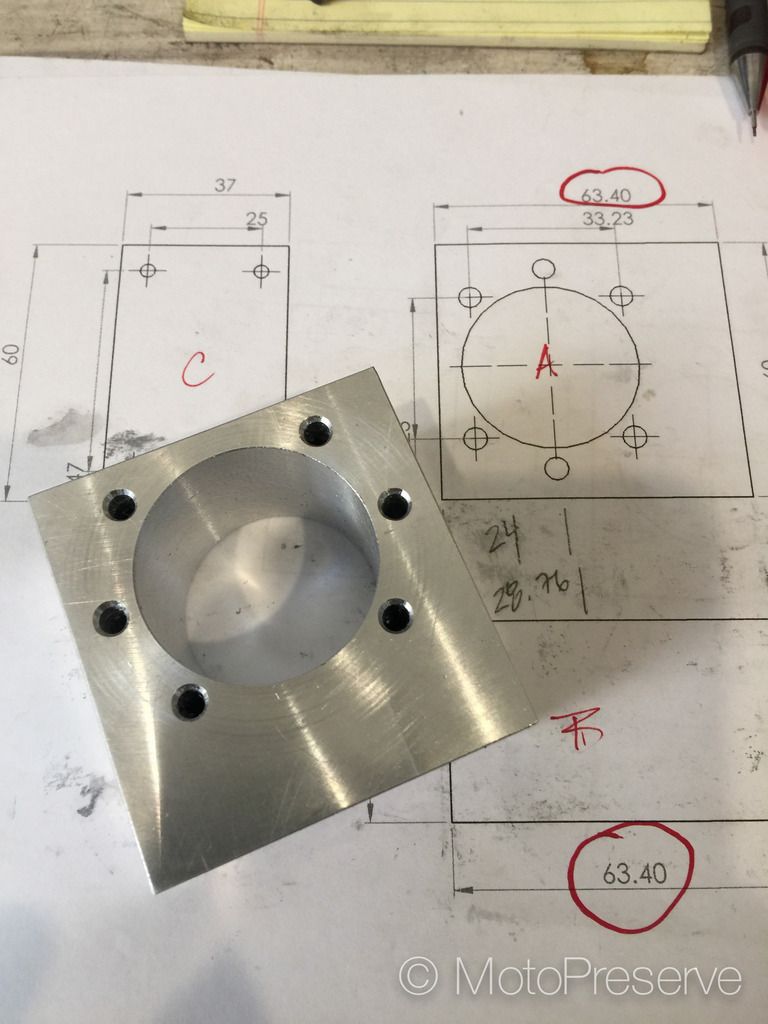

Mock-ups prevent headaches...

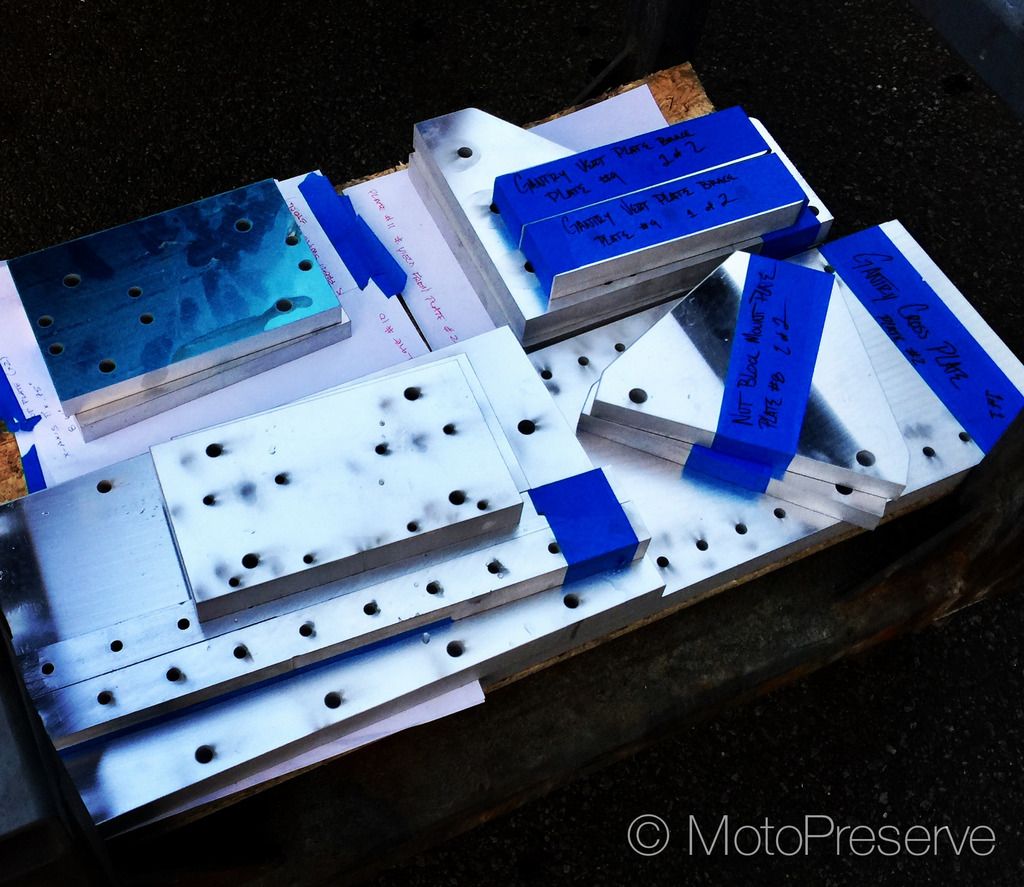

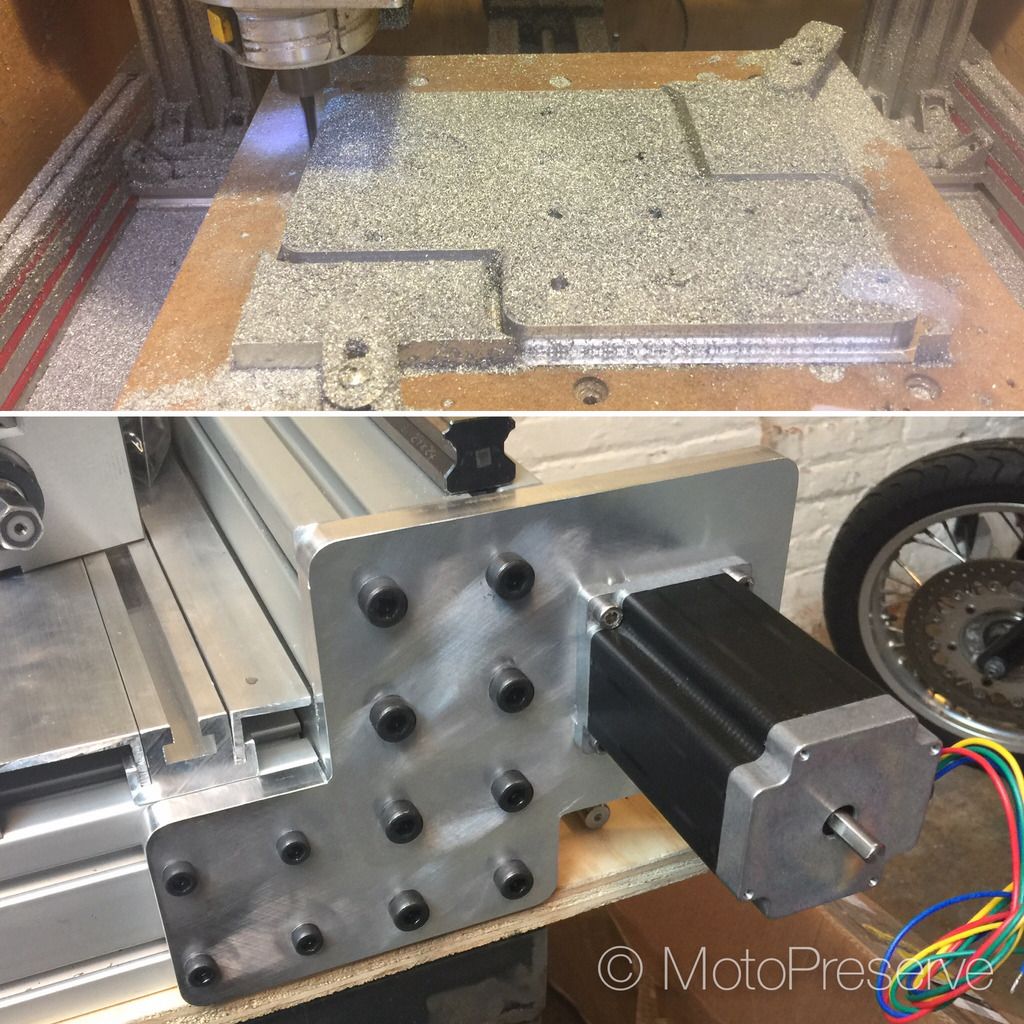

Tooling plate back from water-jetting...

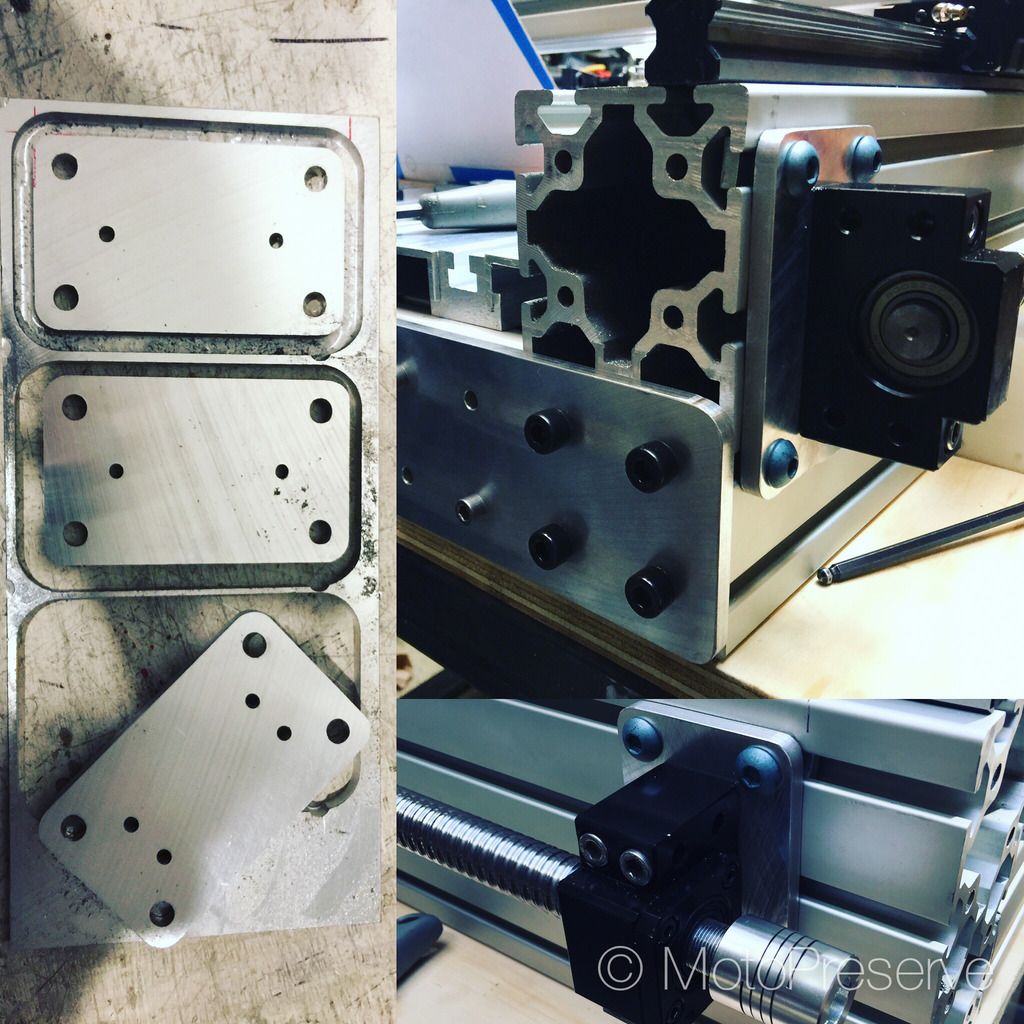

The gantry...

Starting to look like a machine...

- - - Updated - - -

Custom ballnut blocks...

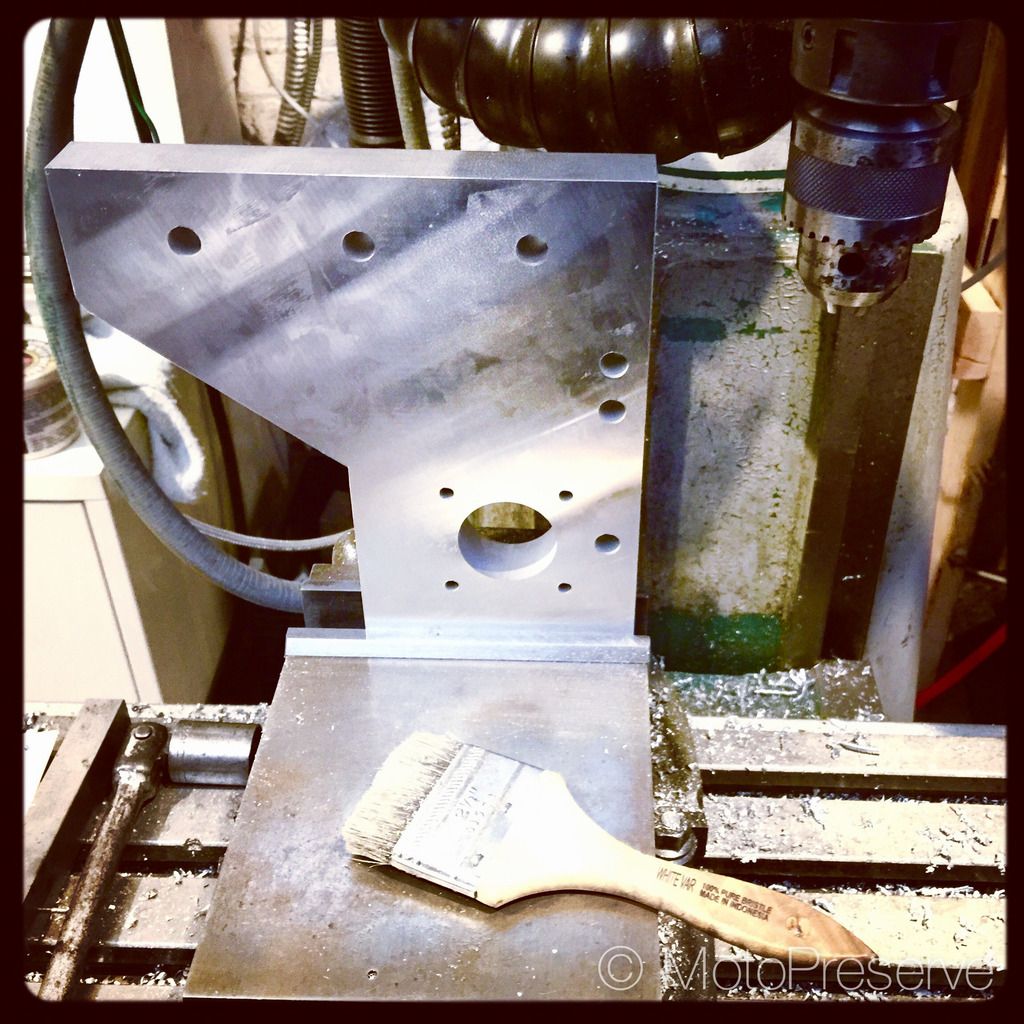

Making parts for the new CNC on the old CNC...

the little CNC worked well, but the vertical mill (Millrite) was priceless...

Results 1 to 19 of 19

Threaded View

-

06-15-2017, 02:27 AM #1

Registered

Registered

- Join Date

- Jul 2015

- Posts

- 37

DIY Gantry-CNC heavily influenced by CNCzone...

Similar Threads

-

Gantry mill with moving gantry for Z-axis

By rogue-insight in forum Vertical Mill, Lathe Project LogReplies: 25Last Post: 09-07-2020, 01:32 PM -

Heavily CNC converted Opti BF 20 Vario

By JMI80 in forum Benchtop MachinesReplies: 76Last Post: 04-15-2012, 02:34 PM -

Heavily vibrating motors when stationary.

By Gaz. in forum DIY CNC Router Table MachinesReplies: 3Last Post: 03-20-2011, 04:50 PM -

Gantry: planning to design moving open gantry

By rdcd in forum Mechanical Calculations/Engineering DesignReplies: 0Last Post: 11-14-2009, 10:52 PM

Reply With Quote

Reply With Quote