Agreed.. But you can do rough positioning - usually good enough for orienting the spindle...

https://www.youtube.com/watch?v=D6dGYsXAPIU

Thread: Closed Loop CNC

Results 41 to 60 of 99

-

07-01-2018, 04:27 PM #41

Registered

Registered

- Join Date

- Jul 2003

- Posts

- 1754

Re: Closed Loop CNC

-

07-01-2018, 04:54 PM #42

Registered

Registered

- Join Date

- Jul 2003

- Posts

- 1754

-

07-01-2018, 05:12 PM #43

Registered

Registered

- Join Date

- Jul 2003

- Posts

- 1754

Re: Closed Loop CNC

Linuxcnc is a closed loop control at its heart.. Even its step generators feed back its internal position to motoin. That is why it is easy on linuxcnc to use feedback even with steppers. You hook the encoders in - then instead of using the step generator feedback to motion - you use the encoder. or whatever.

sam

-

07-01-2018, 05:41 PM #44

Re: Closed Loop CNC

Of course if you want servo type control with a VFD and 3 ph motor, the VFD has to have the encoder option.

In this way you can go down to 200% torque at zero RPM and this is used in elevator/lift control as well as holding a load stationary in the case of a gantry crane lifting a load.

As well as tool change orient options etc.

Some years ago I watch a demo by one VFD company using the crane lift approach.

See encoder with vector VFD in the PDF.

Al.CNC, Mechatronics Integration and Custom Machine Design

“Logic will get you from A to B. Imagination will take you everywhere.”

Albert E.

-

07-01-2018, 08:27 PM #45

Member

Member

- Join Date

- Jan 2005

- Posts

- 15362

Re: Closed Loop CNC

Dreaming is good, rough positioning, it is

But if he has 2 VFD drives, and is asking about servos to close the loop, this is 2 different things, yes everyone already knows, that most spindle orienting is done this way, this is not being used for 2 axes control with any kind of accuracyMactec54

-

07-01-2018, 08:29 PM #46

Member

Member

- Join Date

- Jan 2005

- Posts

- 15362

-

07-01-2018, 09:49 PM #47

Registered

Registered

- Join Date

- Jul 2003

- Posts

- 1754

Re: Closed Loop CNC

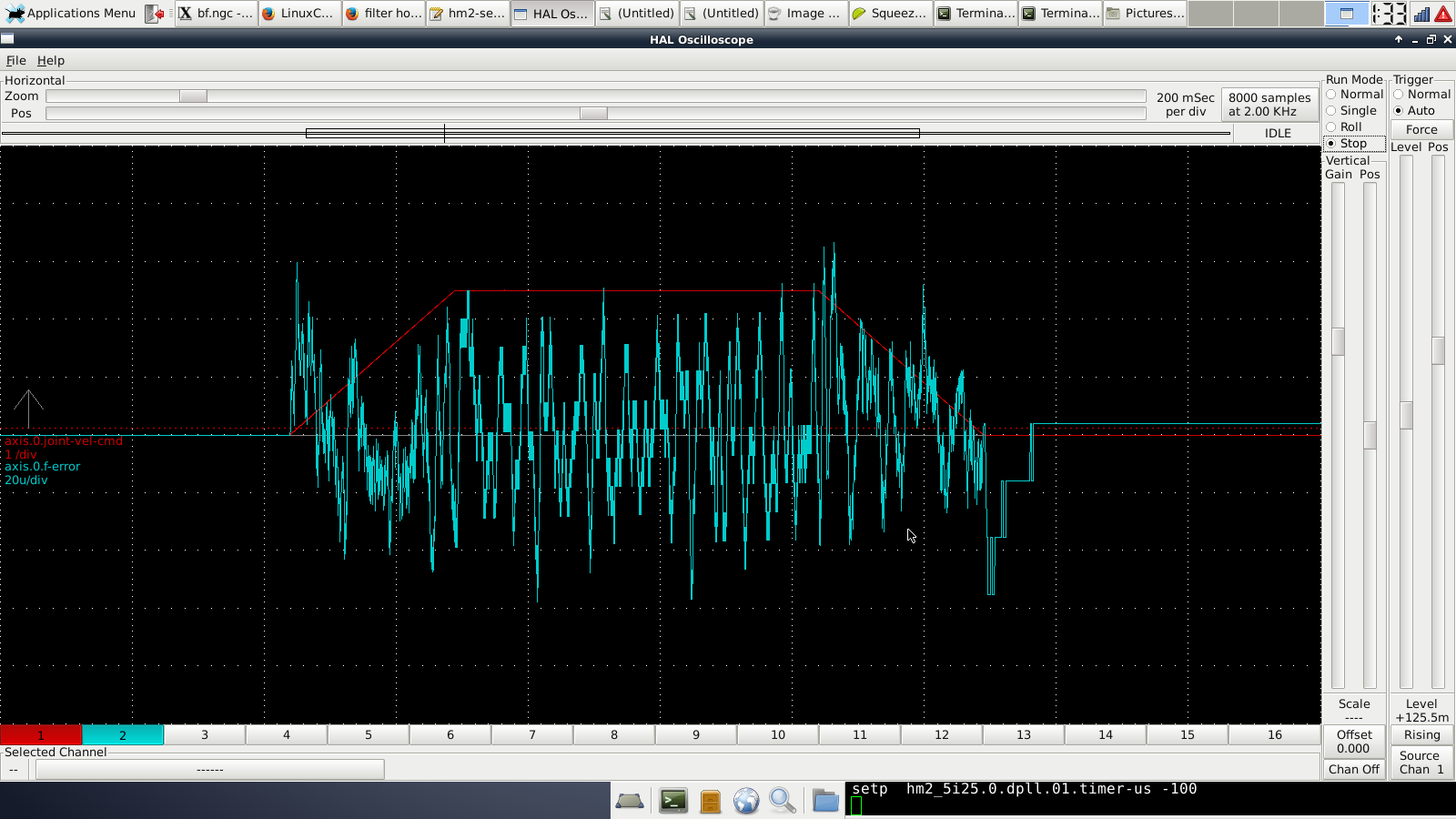

maybe. but it works very well.. This was initial tuning with some PWM input amc drives. That is <.0003" following error at 150ipm. (and it is tuned much better now...)

https://www.youtube.com/watch?v=lTNzBLNBNiE

-

07-01-2018, 10:00 PM #48

Registered

Registered

- Join Date

- Jul 2003

- Posts

- 1754

Re: Closed Loop CNC

Here we go.. <.00007" following error at 150ipm... Not bad for old junk.

-

07-02-2018, 04:30 AM #49

Gold Member

Gold Member

- Join Date

- Apr 2006

- Posts

- 3498

Re: Closed Loop CNC

awesome that is <0.002mm...

http://free3dscans.blogspot.com/ http://my-woodcarving.blogspot.com/

http://my-diysolarwind.blogspot.com/

-

07-02-2018, 05:50 AM #50

Member

Member

- Join Date

- Jun 2010

- Posts

- 4256

Re: Closed Loop CNC

In the case of a stepper system, you don't know. But if you overload the stepper motor even briefly, the job is probably trashed. That is a deficiency of the any system based on open loop steppers. You can't try to instruct a stepper motor to 'have another go please'. That said, please note that there are probably thousands of hobby-level stepper systems around the world, spinning away happily.How would the controller know that the Drives / motor combo has obeyed the command unless three is an encoder feedback connected back to the controller.

In the case of a digital servo system, you can normally configure the driver to flag a fault if the encoder does not keep up. Typical tolerances can be 8 steps, 64 steps, 256 steps, etc. Such a fault will nomally crash-stop the whole CNC machine. Note that for many such systems, the single step resolution can be <1 micron, so if the system lags by a few steps, you are talking about only a couple of microns error.

Little Gecko servo drivers in include red, orange and green LEDs for the various error margins which you can monitor by eye for a while, to get some idea of how the system is going. I imagine other brands do likewise.

Cheers

Roger

-

07-02-2018, 02:05 PM #51

Registered

Registered

- Join Date

- Jul 2003

- Posts

- 1754

Re: Closed Loop CNC

Linuxcnc can also do ethercat. (although i have no experience with that..)

https://forum.linuxcnc.org/24-hal-co...r?limitstart=0

sam

-

07-02-2018, 03:03 PM #52

Member

Member

- Join Date

- Jan 2005

- Posts

- 15362

-

07-02-2018, 04:24 PM #53

Registered

Registered

- Join Date

- Jul 2003

- Posts

- 1754

Re: Closed Loop CNC

How does that make any sense? The trace shows that the system resolution has to be better than .00007 / inch (it is actually .000019") so the system is tuned within +/-4 counts. You are seriously saying that if I had a higher cpr encoder I would not be able to tune it to .00007 error?

To answer your question - this is 500cpr or 2000 counts per rev. I might consider it on the low end of resolution. This gives an axis resolution of 50,800.1 counts per inch.

And - all the mesa hardware is doing is counting the encoders and sending out high speed pwm. The pid loop , motion is all within linuxcnc.

sam

-

07-02-2018, 06:33 PM #54

Member

Member

- Join Date

- Jan 2005

- Posts

- 15362

Re: Closed Loop CNC

Just as I thought, unless your Encoders have 16Bit to 20 Bit 1 million CPR you are just pretending you have something great, the number you present are meaning less, to what the over all performance would be, which is very poor, with a low resolution like this

As I said the Masa is doing all the work, without it or another board like it, the LinuxCNC would have a dismal performanceMactec54

-

07-02-2018, 07:14 PM #55

Registered

Registered

- Join Date

- Jul 2003

- Posts

- 1754

Re: Closed Loop CNC

Huh. Are you talking about something like this?

DMM | ABS-14-00 Absolute Encoder | AC SERVO DRIVE | AC SERVO MOTOR | ROTARY ENCODER

Wow - 16 bit encoder - that would be 65535 counts per rev!

Lets look at the spec - accuracy.

12-bits / 4096 / 0.088° / 316 arc-sec

wait what? - it is only twice as good as my 2000 count encoder? Not to mention the possible acceleration lag inherent to magnetic encoders?

Who is pretending?

-

07-02-2018, 09:46 PM #56

Member

Member

- Join Date

- Jan 2005

- Posts

- 15362

Re: Closed Loop CNC

You are in some kind of dream world, but that is ok, 500 CPR is pathetic, most Hobby Routers are doing way better than this

It has very little to do with accuracy, that is why I said your numbers are worthless, you have very little knowledge of what encoders are used for, you have your head in the clouds, if you think it is for accuracy, which you keep quoting, snip will give you something to think about, this is more than 5 years old, and they go much higher than this, it is the standard today less than 20Bit Encoders and you are not in the playing field

Standard off the shelf general purpose Yaskawa Sigma 7 Servo Motors come with 24 Bit Encoders=16,777,216

20 Bit is 1,048,576 Sigma 5 been in use the last 10 years

24 Bit is 16,777,216 Sigma 7Mactec54

-

07-03-2018, 04:14 AM #57

Gold Member

Gold Member

- Join Date

- Apr 2006

- Posts

- 3498

Re: Closed Loop CNC

500CPR is 2000 ticks (Quadrature) per rotation and if electronics/mechanical gearing( which surely applied with motor as well as in the form of lead screw/rackpinion) then the accuracy is not that bad. No matter how good /high resolution encoder you are using if PID tuning is not done properly it may converted into piece of crap.

http://free3dscans.blogspot.com/ http://my-woodcarving.blogspot.com/

http://my-diysolarwind.blogspot.com/

-

07-03-2018, 09:22 AM #58

Member

Member

- Join Date

- Jun 2010

- Posts

- 4256

Re: Closed Loop CNC

Ha, well, high resolution encoders ... a bit mythical.

One can go to 16 step micro-resolution on a stepper motor, which can make for very smooth movement at slow speeds, but such micro-step resolution only increases the resolution. It does NOT increase the accuracy. The accuracy depends on very fine machining details to do with the teeth inside the motor. This is reasonably well-known.

Given that the best 'low-end' encoder usually runs to only 2,000 quadrature steps per rev, how do these 24-bit encoders work? Dirty little secret: they cheat. They are usually limited to an accuracy of about 2,000 steps. The rest comes from interpolation on the analog signals coming through the encoder wheels. If the encoder wheel is a bit shonky, your accuracy plummets.

You see, the ANALOG optical signal you get from the encoder wheel is a sine-wave, not a digital signal. Honest simple encoders use a simple threshold circuit for 0 and 1, but you can cheat and digitise that sine-wave and feed it through a microprocessor to get another 1,000 steps per encoder slot. With that you can claim 2,000 * 1,000 = 2,000,000 steps per rev. They also do this with high-resolution magnetic encoders - but those vendors seem to be a bit more honest about what they are doing (ime).

A common spec for the 'high-resolution' encoders used to be that they transmitted the encoder signal as a data stream, NOT as a bi-phase A & B, although it should be possible these days to generate a pseudo-biphase signal. Yes, you SEEM to be getting that resolution, but you are NOT getting that accuracy. The encoder slots in the wheel are not etched to that precision.

Should anyone have specs on encoders which do claim 24-bit ACCURACY, I would love to see them (and their price).

Cheers

Roger

-

07-03-2018, 12:15 PM #59

Registered

Registered

- Join Date

- Jul 2003

- Posts

- 1754

Re: Closed Loop CNC

The thing is - I have have some real world examples showing how linuxcnc is positioning...

You can see the previous screenshot of following error that the system is following trajectory within .00007". It is the whole system.

how about this?

https://www.youtube.com/watch?v=FgOqEz5Tk-Y

or doesn't this count either because my encoders are only 2540 line or 10160 counts... It isn't just the encoders - it is the whole system as khalid mentioned.

sam

-

07-03-2018, 02:27 PM #60

Member

Member

- Join Date

- Jan 2005

- Posts

- 15362

Re: Closed Loop CNC

As I said accuracy has very little to do with it, you can get that same accuracy as you are quoting by using a Stepper motor with no Encoder

So now you have some magic going on, you changed from 500 PPR encoders to 2540 PPR encoders ???? it still does not make any difference, you will still have a dismal performance with a system like this

Please Note without the MESA Breakout Board ( which is doing all the work, )[/U] the LinuxCNC control is no better than any other cnc control, I'm not against LinuxCNC I use it also, along with lots of other controls that perform and do the same job, some do it better

You have to catch up, 20 Bit Encoders have been in the industry and for some hobby users that want them for 10 years, if you are just pretending at Hobby level then that is fine, dinosaurs have been gone for a long time, so stop pretending that you have something that is great, when in reality it is a dinosaur

Seeing you brought up the subject of magnetic Encoders, here is a test with a true 16 Bit, lets see you do this with you 500PPR Encoders, it's not going to happen, and note no closed loop control required the loop is closed in the servo drive for this test

https://www.youtube.com/watch?v=fyKBKUkFJVAMactec54

Similar Threads

-

Closed loop servo vs real close loop in motion controller

By ciufuliciboy in forum Servo Motors / DrivesReplies: 25Last Post: 04-21-2018, 04:36 AM -

Closed loop microstepping - similar torque penalties to open loop? Questions...

By j3dprints in forum Stepper Motors / DrivesReplies: 1Last Post: 01-05-2018, 05:19 AM -

Closing the loop with Path Pilot. Possibly dual (global) closed loop?

By SwampDonkey in forum Tormach Personal CNC MillReplies: 29Last Post: 05-04-2016, 09:39 PM -

Encoder connection from closed loop to semi-closed loop

By botha.y in forum FanucReplies: 0Last Post: 03-13-2012, 11:15 PM -

Closed Loop Driver vs. Closed Loop Computer

By ojibberish in forum Gecko DrivesReplies: 3Last Post: 06-08-2004, 05:30 PM

Reply With Quote

Reply With Quote