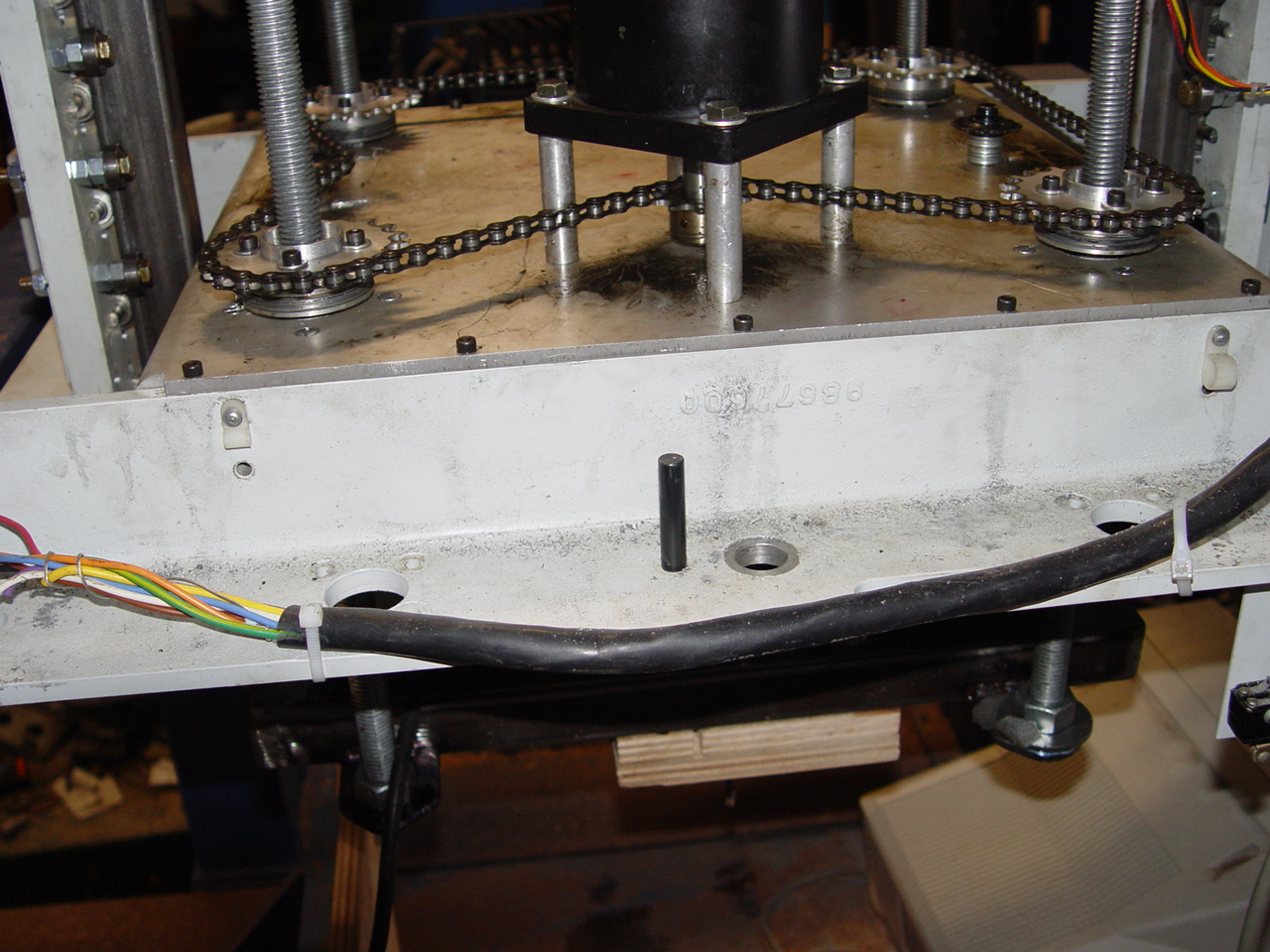

I'm going to put this into cnc terms but this is not for a cnc router. It is for a home made saw mill. This mill has only an x and z axis. My question is for the z. What I have is four acme rods placed aprox 40" square holding the z "carriage" this carriage carries the weight of a 25hp Wisconsin engine and the bandsaw itself. Estimated weight of 600 lbs. Each side of the acme rods are connected by 1" ss rod with mitered gears with a chain drive between the two rods. There are four brass acme nuts on the top of the carriage, and four on the bottom (approx. 24" apart) The fellow that built this spared no expense and knew what he was doing. It is a great idea BUT, will it work? I am concerned of the play (which is minimal) between mitered gears and chain drive with the timing of all four acme rods. It would seem to me that binding might be a problem. What do you think? Thanks in advance!

--Rick

Results 1 to 9 of 9

-

04-22-2007, 04:40 PM #1

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 39

4 Acme rods for a Z...Will it work? Help please!

4 Acme rods for a Z...Will it work? Help please!

-

04-24-2007, 12:30 AM #2

Registered

Registered

- Join Date

- Jan 2006

- Posts

- 153

Let me start by saying that sure sounds like a cool machine! (I want one)

From what your describing it sounds like the weight of what is on the Z is supported by 4 screws with brass nuts and drivin by chains. I don't think you have to worry about play because it will always have a load one way (the weight of the saw). Binding may be a problem if your motor isn't sufficiant to do the job. I think I would consider building a preload system (counter balance) but I would hook it to the motor some how so it always keeps the load on the chains and screws, then you may be able to pull it off. Then again it could fail if the saw cutting reduces the load.

-

04-24-2007, 12:34 AM #3

Registered

Registered

- Join Date

- Jan 2006

- Posts

- 153

After a closer inspection of what you posted I see your just concerened if it will work running it by hand. A picture would be worth a thousand words.

-

04-24-2007, 02:36 AM #4

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 39

The weight is supported by the four acme screws by the eight brass nuts (four on top, and four on the bottom). The screws are turned by mitered gears, 2 each on 1" s.s. rods. The two rods are connected by a chain drive with one rod connected also by chain drive to a 1/2 hp 1800 rpm DC motor with a very large gear ratio (not sure of the ratio). Should have plenty of torque. This is a machine I am looking to purchase that is incomplete. I'm not sure if I would complete it as was intended. I'm not too concerned of the weight on the acme rods, but am concerned of the timing between four rods. It would seem to me that any play at all would cause binding. This may be unwaurranted. I've attached the best pictures I have to show this. It has a separate DC motor for the guide adjustment. I would want to computerize the Z and X axis if I do make this purchase which I am leaning to. Too much of the really good figured stuff always gets set to the side. I want my share! So it would be a CNC saw mill.

Thanks for the reply. I was really hoping for a lot of input on this before making the purchase.

--Rick

-

04-25-2007, 04:59 AM #5

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 39

OK...It's mine now...Another project!

OK...It's mine now...Another project!

I'll pick this machine up in a few weeks and will be posting more pictures. It's got a really good engine, new clutch set up (really smooth) and the saw itself is built like a tank. completely rebuilt '46 Dodge powerwagon hubs turning 26" Cook band wheels. Cook blade guide system, sweet blade tracking set up...Nice! Might have to make some design changes to the Z but I really liked what this fellow did. Beautiful work, just not complete. Still would like more input on the original question of the four acme rods??? Can't wait

to get it to the shop, build the X carriage, log dogs, loader, add the motors, drives, hydraulics, etc...etc...

to get it to the shop, build the X carriage, log dogs, loader, add the motors, drives, hydraulics, etc...etc...

Should have an easy 30 grand plus band mill for 5 + or -...usually +++ ...More to come! Gunna be a sweet project!

--Rick

-

04-25-2007, 01:36 PM #6

Registered

Registered

- Join Date

- Jan 2007

- Posts

- 211

Without a lot of waffling around, I think it will work. I have seen chain drives that have a LOT more slop in them used to do the same sort of thing. When those four screws turn, it is going to go up and down.

-

04-25-2007, 01:46 PM #7

Registered

Registered

- Join Date

- Jul 2003

- Posts

- 1754

-

04-29-2007, 05:57 AM #8

Registered

Registered

- Join Date

- May 2005

- Posts

- 8

I work in an architectural millwork shop, and both our 24" planer and 36" wide belt sander use a 4 post screw arrangement with a chain. Both machines work flawlessly, and to an accuracy of a couple thousandths. I know the sander is driven with sprockets on the posts and an idler like the picture above. As long as the gears don't develop enough slop to jump teeth you shouldn't have a problem with alignment. Also, both machines have rubber boots covering the threads, keeps the dust out, mcmaster carr sells them, others too I'm sure...

-

04-29-2007, 01:12 PM #9

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 39

Thanks for the replies. I'm sure that it will work. I'm going to add some rails and roller bearings from the carriage to the frame as right now the four acme rods are all that keep it from moving side to side or forward to back. I have the bellows from Mcmasters already mounted, just not stretched, but am concerned as to how they will hold up when the big chips start flying. Might get some heavier duty bellows. They are expensive! I'll know more when I pick this machine up and get it to my shop. Thanks!

--Rick

Similar Threads

-

Art work

By Art Ransom in forum Employment OpportunityReplies: 8Last Post: 10-16-2006, 03:01 PM -

Looking for work

By JPMach in forum Employment OpportunityReplies: 1Last Post: 09-01-2006, 06:47 PM -

art work

By tmt_92021 in forum MastercamReplies: 6Last Post: 08-19-2006, 01:21 PM -

Need Work

By j-radkemachine in forum Employment OpportunityReplies: 0Last Post: 07-10-2006, 10:01 PM -

PWM how does it work?

By cncadmin in forum Mach Plasma / LaserReplies: 9Last Post: 08-16-2005, 05:25 PM

Reply With Quote

Reply With Quote