I got a small used cnc mill a year or 2 ago and have not had a chance to go through it and fix it up. The ways (sliding surfaces) look really good - but most everything else needs a little TLC. (ball nut mounts not parallel to the slides and such)

The mill is torn down to its individual parts and being gone through. Currently working on the Z axis slide. Again - the sliding surfaces look great - but the mating surfaces are a bit off.

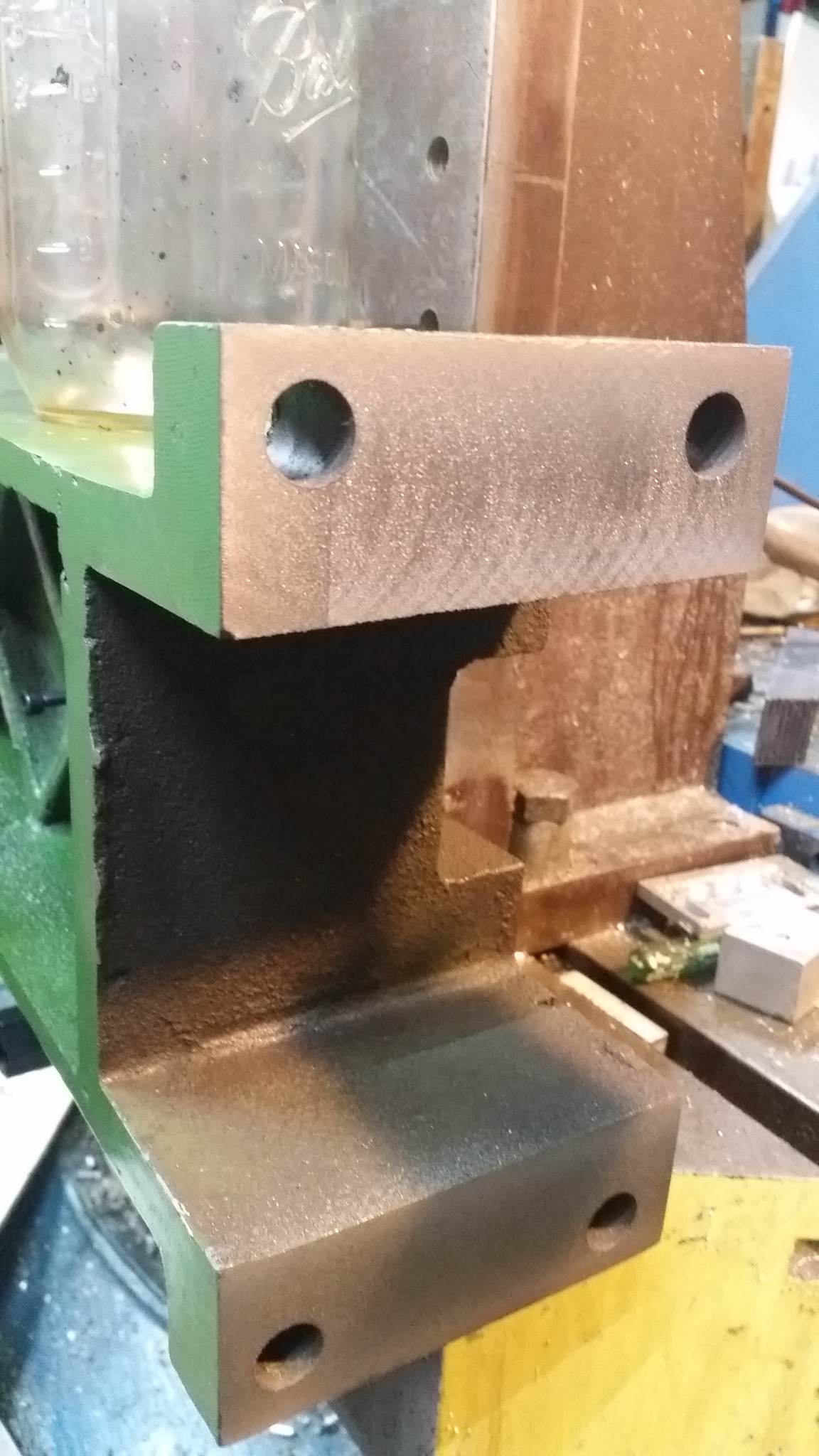

What to do.. Mount it on the big mill of course!

Using some ground rod/123 blocks to make sure the ways are parallel and perpendicular to the K&T.

True up the mounting surfaces... (took off about .002")

And done..

Things to do yet on the Z axis column..

- mill the relief for the ball screw nut further. (go into the more later)

- mill the mounting holes so they are symetrical. (they are all over the place.)

- mill some line up edges for mounting to the base. (I am adding a 4 inch riser block so there is more space between the spindle and the table)

I think that is it for now.

Thread: small mill project.

Results 1 to 20 of 46

Threaded View

-

09-25-2018, 06:15 PM #1

Registered

Registered

- Join Date

- Jul 2003

- Posts

- 1754

small mill project.

Similar Threads

-

small EDM project (DIY EDMers welcome!)

By acannell in forum EDM Discussion General TopicsReplies: 6Last Post: 01-08-2014, 02:41 PM -

My Manual small mill project

By ZipSnipe in forum Vertical Mill, Lathe Project LogReplies: 95Last Post: 05-07-2013, 05:03 AM -

Need Help with Small Project

By mgilbert754 in forum MetalWork DiscussionReplies: 1Last Post: 08-17-2007, 05:37 PM -

Small Mill Part/Project/Thing Showcase

By BrendaEM in forum Benchtop MachinesReplies: 5Last Post: 08-01-2007, 06:25 PM

Reply With Quote

Reply With Quote