I'm sharing my experiences and explaining that it is not easy for me and that I'm no more interested to learn a full OS. I'm sorry if my posts hurt your feelings.You apparently do care because you keep making posts about how its hard to use, impossible to set up the OS, impossible to set up LinuxCNC, Linux and LinuxCNC are not mystical things that you need a computer science degree to use. That is not true and to use LinuxCNC you don't need to learn the OS.

Thread: CNC Motion Control Board

Results 61 to 80 of 82

-

01-16-2019, 03:56 AM #61

Registered

Registered

- Join Date

- Jun 2015

- Posts

- 943

Re: CNC Motion Control Board

-

01-16-2019, 04:00 AM #62

Registered

Registered

- Join Date

- Jun 2015

- Posts

- 943

Re: CNC Motion Control Board

Thanks but I have already tried years ago, did not like it. I'm good with Windows, but thanks for the advices.Want to start a program like LinuxCNC, double click the icon, just like windows

Want to transfer files from a USB stick, Insert it and it shows up on the desktop.

Want to open a file, Click File-Open, just like windows.

Want to start an internet browser, Click it.

I had zero Linux experience when I first started using LinuxCNC and I had absolutely no problem. It is a window type system that operates very much like Microsoft windows does. I really don't understand what the mystery is.

-

01-17-2019, 02:56 AM #63

Registered

Registered

- Join Date

- Jul 2003

- Posts

- 1754

Re: CNC Motion Control Board

Years ago.. linux might have been hard years ago - but that has changed. You have no reason to switch as your using a solution tied to windows.

This constant constant repeating that linux is hard and you have to be a programmer to setup linuxcnc is getting old. (not that you are saying exactly that - but it has come up in this thread)

I have setup a matsurra with Geneva tool changer analog servos... Not a lick of code.

sam

-

01-17-2019, 03:09 AM #64

Registered

Registered

- Join Date

- Jun 2015

- Posts

- 943

Re: CNC Motion Control Board

My main problem is linux not linuxcnc, however that is also overcomplicated for me.

For me Linux is alien, because I'm used to Windows, so I don't even know how to properly install something on Linux.

I'm not arguing and also not looking for help as I'm currently not interested in Linuxcnc, I'm just telling how I feel about Linux. I hope it does not offend you too much Linux guys.

Maybe you will make LinuxCNC to work on Windows sometime?! OK I think I know what the answer will be: It will never happen, huh?

OK I think I know what the answer will be: It will never happen, huh?

-

01-17-2019, 04:57 AM #65

Registered

Registered

- Join Date

- Jul 2003

- Posts

- 1754

-

01-17-2019, 05:05 AM #66

Registered

Registered

- Join Date

- Jun 2015

- Posts

- 943

Re: CNC Motion Control Board

That is where external motion controllers come into scope. No need for realtime OS with those.Heh . yah - you know the answer. The original nist version (emc) ran on windows. It used some sort of real time version of Windows NT. There are realtime setups for windows but they are pretty expensive.

What about writting a realtime kernel for Windows like Mach did?

OK I know you guys not interested the same ways like how I'm not in Linux.

-

01-17-2019, 05:15 AM #67

Registered

Registered

- Join Date

- Jul 2003

- Posts

- 1754

Re: CNC Motion Control Board

Art pretty much says he exploited a bug to get his realtime printer port module working. It was still a buffered system (the printer port magic was like a external motion device)

I like the nuts and bolts of it. The realtime subsystem being in the computer really is a benefit. With linuxcnc you have access to the Hal layer - (hardware abstraction layer) that allows you to create realtime 'circuits' connecting internal linuxcnc stuff to external hardware.

Think of it like a breadboard that allows you to do almost anything your heart desires.. (this only touches on the power of it..)

-

01-17-2019, 05:34 AM #68

Registered

Registered

- Join Date

- Jun 2015

- Posts

- 943

Re: CNC Motion Control Board

I don't really beleive in Realtime on a so complex system as a computer. I think it is better to have it on a simpler device like a microcontroller or FPGA which will not hickup, the user cannot overload it like he can a computer.

And how do you run CAM softwares on Linux? Does AutoCAD, Fusion360, Vectric and so on can run on Linux? I like to design while machining and I don't think it's possible with Linux but maybe I'm wrong?!

-

01-17-2019, 05:46 AM #69

Registered

Registered

- Join Date

- Jul 2003

- Posts

- 1754

Re: CNC Motion Control Board

Just because you don't believe doesn't make it not true.. Realtime on linux works very very well. I would go as far to say it works perfectly.

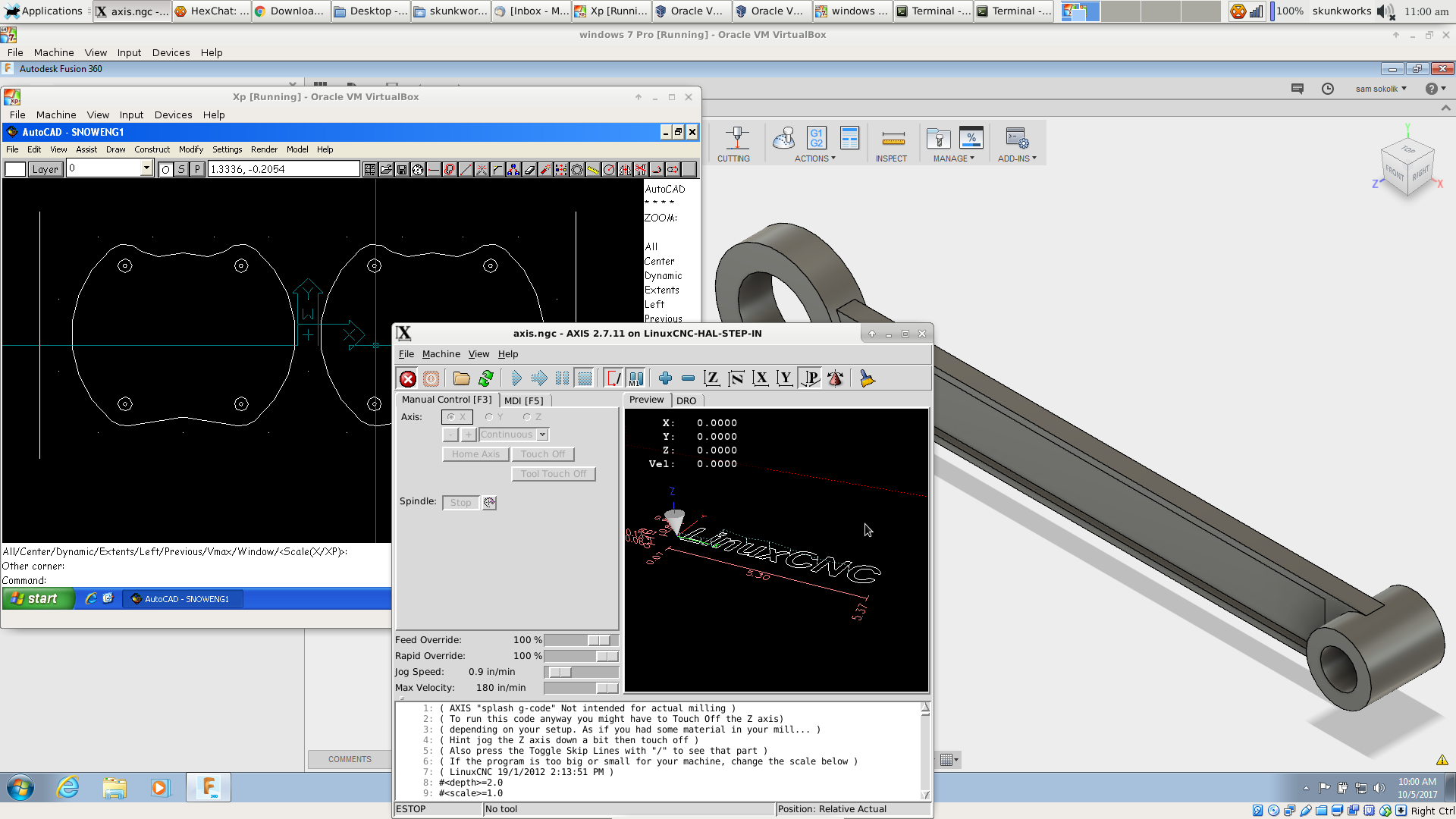

I have tested and loaded down a ton of linux/linuxcnc systems. No issues. I do use a few windows programs still - acad 12 and I have been dabbling in fusion... I run both in virtual machines. I have a XP vm and a 10 vm.

Both vm's running while linuxcnc was running. again - amazing.

Lots running...

-

01-17-2019, 06:12 AM #70

Member

Member

- Join Date

- Nov 2013

- Posts

- 4375

Re: CNC Motion Control Board

Hi,

Forget it, Windows is not and will never be a real-time system.What about writting a realtime kernel for Windows like Mach did?

Windows uses the interrupt system very extensively to signal between threads, synchronize threads and so on over and above all the usual

hardware uses of the interrupt system. Consequently when we come along and start trying to write realtime code OUR interrupts get assigned a

lesser priority. You might try artificially increasing the priority of our interrutpts but then we crash Windows.

Linux does not have that restriction, or rather with the realtime extensions (RTE and RTA ) user interrupts get top priority. My LinuxCNC

latop exhibits about 2.5us of jitter......not bad, that's about 10% at a kernel frequency of 40kHz

There is a way to graft real time performance onto Windows. A good example is:

https://www.intervalzero.com/.

It has a realtime scheduler running in one core of the CPU and yet has Windows running in the remaining cores and a clever data sharing

arrangement. Windows cannot ever block the reatime core. When I investigated it was going to cost $16000 USD for me to get started

and still have to licence each installation. It just not an economic proposition.

Thus if we exclude the 'funny money real time Windows solution' there are three choices:

1) Use Linux with real time extensions and LinuxCNC

2) Use Windows and a buffered real time motion controller

3) Use dedicated real time hardware .....read Fanuc.....Seimens etc.

Linux and LinuxCNC is free and uses readily available cheap hardware.

Windows is not free but not expensive either $100-$200, a realtime controller for $120 upwards and a software solution like UCCNC or Mach.

Fanuc and Seimens are many thousands or tens of thousands of dollars with a recurring licence fee as well!

The supporters of LinuxCNC have argued VERY cogently for its use in this thread.

I use an Ethernet SmoothStepper which has an effective kernel speed of 4Mhz, such is the speed of a hardware solution. In reality I don't require

any thing like that sort of speed but I do signal my servo driven spindle at 458kHz so I do make use of the speed on offer.

The cost of my PC, the SmoothStepper and Mach4 is about $1000 USD. My mill cost about $8000 in parts and materials. Thus the cost of the

Windows solution is only a modest fraction of the total.

My recent experiments with LinuxCNC suggest I could have a good solution even cheaper. My complaints abut the difficulty in using Linux have

been eliminated with the ever increasing sophistication of the Linux GUI's.

Craig

-

01-17-2019, 09:47 AM #71

Registered

Registered

- Join Date

- May 2015

- Posts

- 686

Re: CNC Motion Control Board

This was not really that hard back when he started. Back in about 1991, I created an interface to drive a heap of relays and I wrote interrupt driven interface to trigger the ports via the parallel port interface.That was 10 years before Artsoft who wrote Mach3 was founded. I used this to control a window display for the local apple and grape festival in Stanthorpe, a country town in Australia. I didn't know then I had created a breakout board as it faithfully churned away emptying and filling wine bottles attached to a bottle filling machine and turning the handle of the wine press in the window display and updated a silly simulation console on a laptop visible in the shop window. I won some very nice crystal which I still use today when I have a scotch. However, had I known what I'd invented, I'd be a rich man today but as always my ideas were ahead of their time....

And yes it ran on a Microsoft OS that predated Windows which was very much in its infancy as ithe internet had not been invented... Well Australia certainly wasn't connected until some time afterwards.Rod Webster

www.vehiclemods.net.au

-

01-17-2019, 10:35 AM #72

Registered

Registered

- Join Date

- May 2015

- Posts

- 686

Re: CNC Motion Control Board

Craig, this is still not particularly fast. Some people are using LinuxCNC with a 4Mhz Servo thread. The Mesa external step generators run at up to 10 MHz... However the difference is that with a smoothstepper you are limited to the features are in the hardware. LinuxCNC's best kept secret is the ability to write your own components which once compiled and installed with the halcompile program becoe an extension of LInuxCNC. Yes you neet to be able to code in C but with so many people playing with arduinos today, this is not a major drawback.

Rod Webster

www.vehiclemods.net.au

-

01-17-2019, 10:56 AM #73

Registered

Registered

- Join Date

- Jun 2015

- Posts

- 943

-

01-17-2019, 11:04 AM #74

Registered

Registered

- Join Date

- May 2015

- Posts

- 686

Re: CNC Motion Control Board

But that might be all they need to write a Linuxcnc component. Its amazing what can be achieved in a component with 10 lines of code. But as samco has said, he built a complex retrofit without coding anything, just using the standard components. So coding is not a requisite, but it is extremely powerful and can't be done with a motion controller card. Just one of the reasons why some of us are converts to the real time capabilities of LinuxCNC.

Rod Webster

www.vehiclemods.net.au

-

01-17-2019, 11:50 AM #75

Registered

Registered

- Join Date

- Jun 2015

- Posts

- 943

Re: CNC Motion Control Board

Coding not possible with motion controllers? Can you please explain this? With Mach3 and UCCNC you can also code if you like, just not needed for basic applications. In Mach in VB and in UCCNC in C#.

-

01-17-2019, 12:58 PM #76

Member

Member

- Join Date

- Dec 2003

- Posts

- 1227

Re: CNC Motion Control Board

I haven't found myself needing to deal with any code at all,which is just as well because I wouldn't know where to start.As for running Windows software under Linux-I haven't yet found anything that won't run in Wine,there may be some out there though.Similarly,I haven't had to fight with installing drivers in years as the Linux distros I have used just found it and made it work.I'm not sure how things are with Windows 10 as I haven't much experience with it and that puts me in a similar position to anybody that hasn't tried using Linux in the last few years.I do know that something like 85% of the web is Linux based and I know of a server that has been running Ubuntu server for almost ten years without any faults.

-

01-17-2019, 01:34 PM #77

Registered

Registered

- Join Date

- May 2015

- Posts

- 686

Re: CNC Motion Control Board

But by your own admission, the real time part of your windows system lives on the motion control board. Please show me an example of plasma torch height control coded directly into Mach3 or UCCNC without the addition of additional THC hardware. I'm not aware of any examples that work in this way becasue you don't have access to the real time part of your CNC system.

I'll leave it to Samco to show you a video for his plasma torch height control managed by LinuxCNC. Its this versatility and extensibility of the real time system that has caused many commercial CNC companies to migrate from Mach to LinuxCNC.Rod Webster

www.vehiclemods.net.au

-

01-17-2019, 04:33 PM #78

Registered

Registered

- Join Date

- Jun 2015

- Posts

- 943

Re: CNC Motion Control Board

I'm not admitting I'm asking, I don't know how it works and you seemed like you know, so I asked how that works.

THC hardware just measuring voltage and generating the THC up and down and arc ok signals. You have to have a hardware which measures the arc voltage, I mean you need that with linuxcnc too right? Or you connecting the hundreds of volts directly to the computer?!

My understanding is that the motion controller is controlling the THC with Mach3 and UCCNC so it is realtime on the motion controller. I guess voltage could be also digitized into the motion controller, it has 2 analog inputs, but I did not try to use that because I have a THC controller.

-

01-17-2019, 05:07 PM #79

Registered

Registered

- Join Date

- May 2005

- Posts

- 1662

Re: CNC Motion Control Board

One that comes to mind is Fusion 360 because it checks for operating system, getting that to run in Wine takes sorcery beyond my skills. CAD/CAM is one of the few reasons I have a Windows license. Virtual machines work if you've got the horsepower and a spare Windows license,

The computers running Linuxcnc in my shop aren't usually used for much else except a bit of text editing. That's a choice and not done out of concern of Linuxcnc misbehaving. In the days when smart hardware was less common I read experienced Mach3 users recommend disabling anti-virus, updates, really all manner of things that might interrupt.Anyone who says "It only goes together one way" has no imagination.

-

01-17-2019, 08:20 PM #80

Registered

Registered

- Join Date

- Feb 2008

- Posts

- 644

Re: CNC Motion Control Board

The chief difference between LinuxCNC and buffered motion control systems like Mach or UCCNC is that the real time motion control parts of LinuxCNC are done at the host

and are therefore accessible to system integrators in a way that buffered systems motion control apparatus is not. In most buffered systems the motion control code is proprietary,

hidden and not user extensible. In contrast LinuxCNCs motion control setup gives users/integrators direct access to all real time motion in an environment with almost unlimited memory and CPU horsepower.

This allows real time customizations that are not practical or even possible with buffered systems, unless the hardware manufacturer adds the feature.

This power and flexibility does come at a cost, it requires that the host computer run a real time operating system.

Reply With Quote

Reply With Quote