I have just converted a 4" rotary table, purchased at Harbor Freight for $99. But it has a huge backlash, as much as 1/5 of a turn on the "handle", this translates into 2 degrees on the table itself.

Is this useable? What is a better rotary table? Is Phase II 4" one good?

Thanks.

Thread: Question on Rotary Table

Results 1 to 20 of 21

-

06-02-2007, 07:41 PM #1

Registered

Registered

- Join Date

- May 2007

- Posts

- 32

Question on Rotary Table

-

06-02-2007, 08:10 PM #2

Try and pick up a Yuasa, one of the best in R.T's

Al.CNC, Mechatronics Integration and Custom Machine Design

“Logic will get you from A to B. Imagination will take you everywhere.”

Albert E.

-

06-02-2007, 08:17 PM #3

Gold Member

Gold Member

- Join Date

- Jul 2005

- Posts

- 12177

On some low cost rotary tables the screw is mounted in an eccentric bearing housing which can be rotated to move the screw closer to the gear and reduce backlash. Does yours have this feature, you may be able to adjust it.

An open mind is a virtue...so long as all the common sense has not leaked out.

-

06-02-2007, 08:32 PM #4

Registered

Registered

- Join Date

- May 2007

- Posts

- 32

Yes, it has a set screw on the side, but I have tightened it to the point that it could not be done any more. It helped a little, now backlash is down to about 1.5 degrees for the table itself.

I am supperized that this R/T is made in India and has such poor quality. I openned it up, the inside tube is rusty, the T-slot finish looks like some kid carved it with a knife. The bottom bearing housing (not bearing itself however) was rusty, too. This is supposed to be BRAND NEW from HF.

I will disassemble it and try to put it back together. I think I am going to use it for my object movie photography, not for machining.

But thanks for your info.

-

06-02-2007, 08:56 PM #5

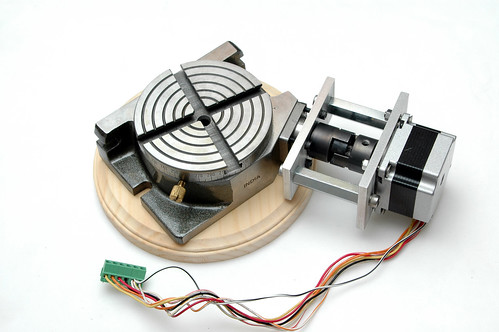

This is an example of one I picked up on ebay for $120.00, silky smooth and no detectable backlash.

Probabally cost $600+ new.

Al.CNC, Mechatronics Integration and Custom Machine Design

“Logic will get you from A to B. Imagination will take you everywhere.”

Albert E.

-

06-02-2007, 09:34 PM #6

Registered

Registered

- Join Date

- May 2007

- Posts

- 32

I probably should have bought an used one. I read at "mini-lathe.com" that these are very bad R/T's. I bought that one on HF web, for some reason the mark -- "india" was erased on HF web's photo.

Thanks for the info. I will keep an eye on eBay to get a Yuasa.

-

06-02-2007, 10:42 PM #7

Many of those cheap rotaries have very little in the way of thrust compensation on the worm screw, as in a shoulder bears against the main casting body. You might be able to figure out a way to make a precision shim washer or something to fill any gap present and it may make the thing more tolerable to use.

First you get good, then you get fast. Then grouchiness sets in.

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

06-02-2007, 11:33 PM #8

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 113

I retrofitted a Phase II 4" table and it has no backlash. But I also added thrust washers behind the handle nut.

Dan

-

06-03-2007, 05:58 PM #9

Registered

Registered

- Join Date

- Mar 2004

- Posts

- 150

Is something like this any good?

-

06-03-2007, 07:28 PM #10

Registered

Registered

- Join Date

- May 2007

- Posts

- 32

OK, I will get Phase II 4" R/T then.

On my conversion, I actually added a thrust bearing bought from McMaster. It is hidden inside that front mounting plate which is 1/4 inch thick. I have no complains at "handle" part, no backlash as I was really carefull. It is the gears engagement section that has all the backlashes.

-

06-03-2007, 07:33 PM #11

Registered

Registered

- Join Date

- May 2007

- Posts

- 32

I think the one I got does have thrust bearing instead of bearing against the main casting body. I believe it is the worm and worm gear (if I used the terminoloy right) that generates all backlash -- I can feel it, when I turn the coupler by hand, there is always this "free" zone, then I can feel that the gears are engaged.

Anyways, I just tested it out, it seems to be pretty good at handling vertical loads, I think I put about 50 lbs on it, with my 50 oz-in unipolar stepper, it runs smoothly. So I will use it for my photography hobby :-)

-

06-03-2007, 07:51 PM #12

Registered

Registered

- Join Date

- May 2007

- Posts

- 32

-

06-03-2007, 11:33 PM #13

Gold Member

Gold Member

- Join Date

- Jun 2006

- Posts

- 2512

-

06-04-2007, 12:28 AM #14

Registered

Registered

- Join Date

- May 2007

- Posts

- 32

-

06-04-2007, 01:54 AM #15

Gold Member

Gold Member

- Join Date

- Jul 2005

- Posts

- 12177

This is the type I was referring to, the mesh of the worm with the gear can be adjusted. I have used those on manual machines and with a bit of cleaning have reduced the backlash to around 0.001" to 0.002" at the periphery of the table.

I found it was necessary to fully dismantle them, clean out all the chips, deburr all the sharp edges and then reassemble with good grease.An open mind is a virtue...so long as all the common sense has not leaked out.

-

06-04-2007, 02:40 AM #16

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 357

I'm using a 4" table from LMS. It uses thrust washers and they work pretty good so I just left them alone when I converted it. It has no backlash as it can be adjusted out with the eccentric. It's a pretty solidly built little table IMO.

Steve

-

06-04-2007, 03:42 AM #17

Registered

Registered

- Join Date

- May 2007

- Posts

- 32

Steve, I was amazed by your setup in another thread. Is yours the 1927 at LMS? Or the Phase II one. They seem to be identical except a brand plate on Phase II. I am convinced that I will get a Phase II (or clone) as so many people are saying so.

Steve, one more question, what is that chuck? Is it from LMS as well? Any other accessories needed to mount it on the R/T? Looks great.

Thanks.

-

06-04-2007, 03:04 PM #18

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 357

zwdeal,

The table is the #1927 model. Yes, the independant 4 jaw chuck was from LMS. I had originally bought it for my old 7x lathe. Good quality chuck and turns the cnc rotary table into a very versatile tool. I made the adapter for it but I am pretty sure you can just buy an adapter to mount it to the table.

Steve

-

06-05-2007, 06:43 PM #19

Registered

Registered

- Join Date

- Apr 2005

- Posts

- 403

S_J_H

I like it. What company is LMS? I may need a set up like yours. I have some parts that I need to rotate to machine the adjacient side, and this might be the ticket.

Ron

-

06-05-2007, 11:28 PM #20

Registered

Registered

- Join Date

- Jul 2004

- Posts

- 71

Similar Threads

-

Rotary Table Question

By Cory in forum Haas MillsReplies: 13Last Post: 12-13-2006, 02:43 PM -

and another rotary table question.

By hangslot in forum Haas MillsReplies: 3Last Post: 11-26-2006, 08:41 PM -

Another Rotary table Question

By archer66 in forum Haas MillsReplies: 8Last Post: 11-10-2006, 06:32 PM -

Rotary table question

By Zumba in forum Uncategorised MetalWorking MachinesReplies: 0Last Post: 04-18-2006, 03:04 AM -

Rotary Table Req

By h_2_o in forum Uncategorised MetalWorking MachinesReplies: 9Last Post: 02-08-2005, 08:11 PM

Reply With Quote

Reply With Quote