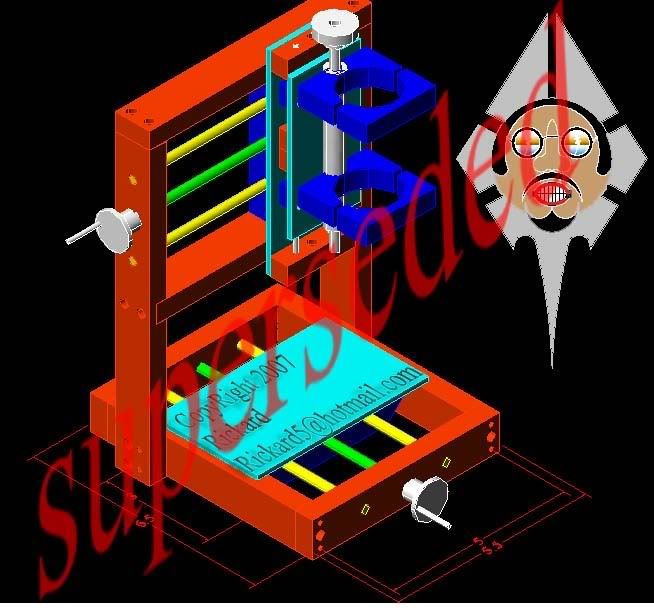

I know this might qualify as a kind of cross-post[/URL] (http://www.cnczone.com/forums/showthread.php?t=40038) , but I am trying to get as many Ideas as possible. What I am trying to design and build is a Vary low cost Desk Top Milling Machine using found parts to keep cost down. To keep the Desk Top to a minimum I have designed it to have a 3”x5” table with an effective working area of 3”x5”. If you look at the Drawing the Orange Rails are going to be 1”x1/2” CRS or Delrin (I Scamed a bunch of ½”x1” Delrin from a client’s shop ) The sea foam plates are 1/8” Delrin. Blue is ½” Delrin. Not shown is the drive motor for the spindle is an R/C Car Motor. The spindle shown is the hand piece for a Dremel hand piece. The Yellow Liner Rods are 1/4” Hardened drive shafts recovers from an old sewing machine. I plan to use ¼”x20 for the lead screws. I’ve got some of the old IBM PC Tandon 5 ¼ floppies I’m scavenging the steppers out of. I’m trying to keep it as light as possible to keep it portable as possible , I plan on mostly milling Brass, Plastic, Magnesium, and some light aluminum. I race Model Cars (SLOTCARS) and get most of the work I do on my Cars, done at the Race Track, so portability is key. I already lug my Taig lathe, and my other tools back and forth. Any Ideas are rely welcome. I am esp. interested on experiences, and advice on LOW COST, Idiot Proof CNC Stepper Controllers I’ve been looking at the FET 3, but I’d like to find a more cost effective all in one solution!

Thread: >$20 CNC Mill

Results 1 to 1 of 1

-

07-07-2007, 09:22 PM #1

Registered

Registered

- Join Date

- Jun 2007

- Posts

- 100

>$20 CNC Mill

Similar Threads

-

Home-Brewed CNC Bench Mill Using Siex X2 Mini-Mill Head

By fignoggle in forum Benchtop MachinesReplies: 18Last Post: 05-12-2009, 05:11 AM -

Coming Down to the Taig Micro Mill or Grizzly Mini Mill.

By CROSSHATCH in forum Taig Mills / LathesReplies: 15Last Post: 01-23-2009, 06:14 AM -

RFQ - milling work on 1/4" wide tool steel - may need azis mill or right-angle mill

By pendentive in forum Employment OpportunityReplies: 7Last Post: 01-22-2007, 02:56 AM

Reply With Quote

Reply With Quote