Morning All & Lurkers - Today brings the steel fibre investigation to a close. Block 4 has been cut out of the bucket. Its quite solid and there was a lot of paste on its top. At best it has 10% by volume fiber in it, which gets 34 low and 40GPa high in modulus. So I may as well buy grout that has 34GPa out of the bag. So I need to get some ALOX, SiC or Alumina to get to E70+. I shall try to get north next week for some ALOX. I'm tempted to knock back the material spec in Milli to 35GPa and move along.... material development is a tough gig.... Peter

Thread: Milli a new composite mill kit

Results 821 to 840 of 2105

-

02-19-2021, 09:52 PM #821

Member

Member

- Join Date

- Jul 2018

- Posts

- 6341

Re: Milli a new composite mill kit

-

02-20-2021, 12:52 AM #822

Member

Member

- Join Date

- Jul 2018

- Posts

- 6341

Re: Milli a new composite mill kit

some info on damping - Peter

-

02-20-2021, 10:37 AM #823

Member

Member

- Join Date

- Jul 2018

- Posts

- 6341

Re: Milli a new composite mill kit

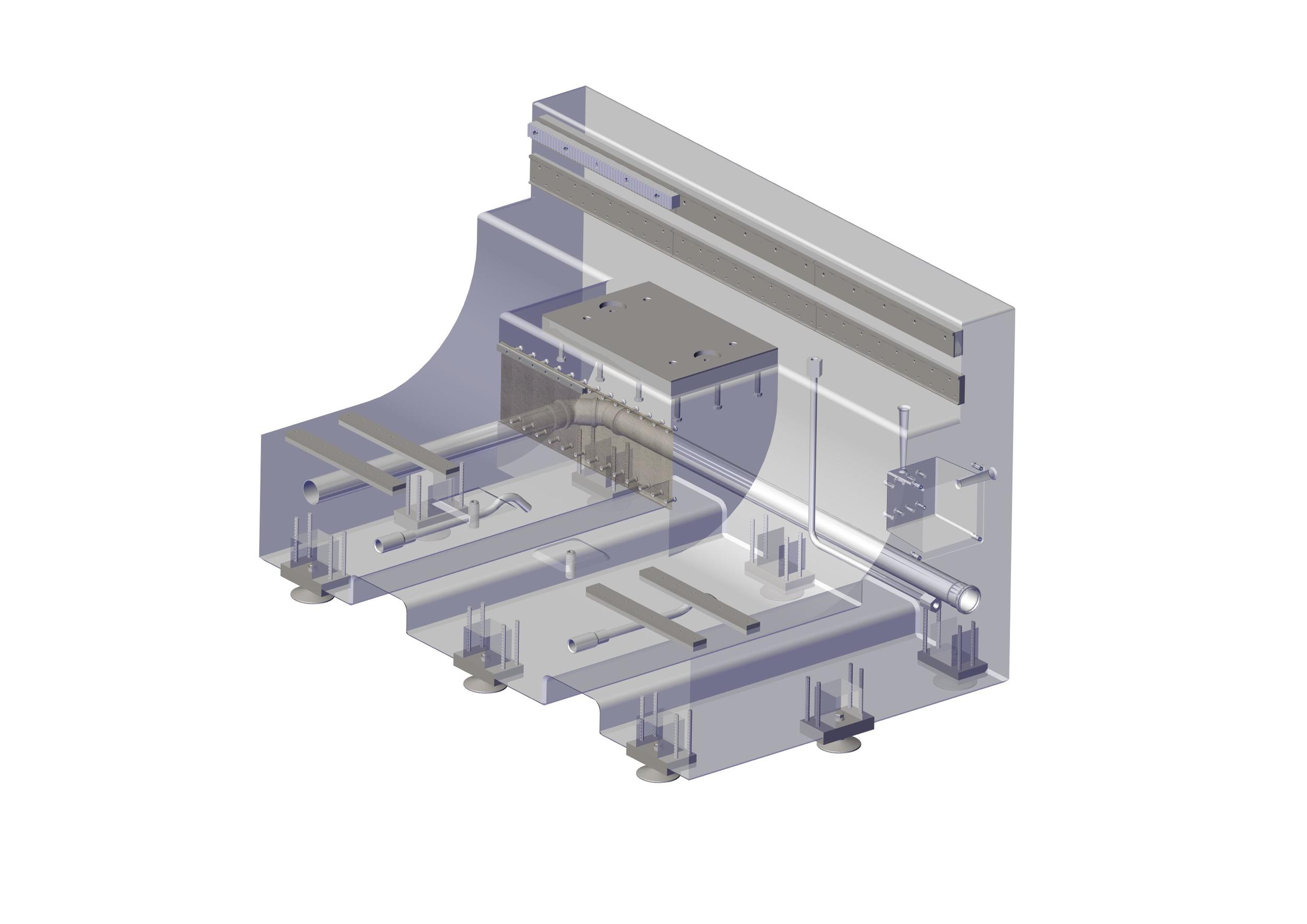

Evening All - Here's a historical lifting gantry machine, been busy finding some SiC and Alumina in china....... Peter

-

02-20-2021, 11:40 AM #824

Member

Member

- Join Date

- Jul 2018

- Posts

- 6341

Re: Milli a new composite mill kit

Evening All - I use Rule of Mixtures a lot thru here so I thought I'd include an example using some moulded plastic. Zytel 35% fibreglass has been around for a long time and has pretty std properties.

A simple explanation of ROM is if you add a glass of 50C water to a glass of 100C water you get 75deg C water when mixed...

https://dupont.materialdatacenter.co...35HSL%20BK039B

Using the attached data and ROM calc shows the strain efficiency of the combination is n=0.85. In my calcs I have always used 0.5 as this is the bottom conservative figure. This is called "translation" ie how does the theory translate to reality... rounded particles don't transfer strain as well as longer fibres do... so round ed (like sand) tend to the 0.5 figure.. I'm getting some ALOX this coming wednesday if I use 0.5 solids ratio (by volume) with CSA I should get E90 (n=0.5 in both). If I use 0.6 solids and epoxy I should get E77 so they are my targets. If I use epoxy its about $17200AUD per m3 and if I use cement its about $11000AUD per m3 so hopefully the grout approach works out...I'm sure I can infuse ALOX I have infused sand before a few times.... Peter

-

02-20-2021, 03:54 PM #825

Member

Member

- Join Date

- Nov 2020

- Posts

- 361

Re: Milli a new composite mill kit

Hey Peter,

Have you thought about the anchors yet? Options:

1. thinner mounting plate + (more) thinner anchors (more balanced?)

2. thicker mounting plate + (less) thicker anchors

-

02-20-2021, 07:53 PM #826

Member

Member

- Join Date

- Jan 2005

- Posts

- 15362

-

02-20-2021, 10:03 PM #827

Member

Member

- Join Date

- Jul 2018

- Posts

- 6341

Re: Milli a new composite mill kit

Hi Ard - I have two thoughts 1) cast the aluminium blocks in then machine all the required features into those blocks on a large router or VMC 2) cast in pockets then epoxy in anodised blocks then finish machine . I'm leaning towards 2) at the moment.... Sometimes aluminium and concrete don't like each other and the Al corrodes so epoxy is a good barrier. If I use steel I'll zinc plate them prior to in-situ casting or post placement... Doesn't affect the CAD work at the moment. Haven't had luck getting the Alumina I want local but a chinses company is quoting on a suitable spec. Local blasting grit is a bit more cost then it should be but it will be fine for casting test blocks, fingers crossed some may arrive tomorrow. I have made the CSA test blocks into trivets and they are now in my kitchen.... I will need to get some granite sealer they are a bit porous and suck up stains.... real machine parts will be sealed and painted. I'll have to get Gully onto that he's good with paint....

Using local materials ALOX/EP E90-95 ~$17000AUD per m3 ALOX/CSA E80-85 $11000 AUD per m3...... Plate Alum at $9/kg $24300 AUD per m3 so not bad.... Peter

CSA CTE 13.7 ALOX 8.1 Alum 21 steel 12 epoxy 45 cast iron 11 units um/m/C

Yong Ju make big machines. I do like BIG machines....

-

02-20-2021, 10:59 PM #828

Junior Member

Junior Member

- Join Date

- Jun 2007

- Posts

- 3891

-

02-21-2021, 03:28 AM #829

Member

Member

- Join Date

- Jan 2005

- Posts

- 15362

-

02-21-2021, 06:54 AM #830

Member

Member

- Join Date

- Jul 2018

- Posts

- 6341

Re: Milli a new composite mill kit

Hi Mactec - Agreed if I contract the machining then st or al does not matter. Once I have a mill I can machine moulds that only have thread inserts vs "blocks". I'd prefer aluminium but will decide once more detail is filled in. Peter

-

02-21-2021, 08:04 AM #831

Member

Member

- Join Date

- Jul 2018

- Posts

- 6341

Re: Milli a new composite mill kit

Hi All - The usual issue with mixing materials is the CTE delta. If I go with the ALOX/EP and I use 60%V alox and 40%EP then the CTE is (0.6*8)+(0.4*45)= 22.8 which is close to AL @ 21 , ST is half that. So aluminium is a good match.. If I use CSA then (0.5x13.7)+(0.5*8) = 10.9 which is closer to steel so the use steel.. Peter

-

02-21-2021, 07:48 PM #832

Registered

Registered

- Join Date

- Sep 2014

- Posts

- 129

Re: Milli a new composite mill kit

Video from Keith Rucker about a metal planer he is restoring: https://youtu.be/OZWD8PlDwn4

-

02-22-2021, 11:34 AM #833

Member

Member

- Join Date

- Jul 2018

- Posts

- 6341

Re: Milli a new composite mill kit

Evening All - I have 25kg of ALOX being delivered tomorrow so can continue the struggle for the Holy E70!! Peter

-

02-23-2021, 03:06 PM #834

Member

Member

- Join Date

- Nov 2020

- Posts

- 361

Re: Milli a new composite mill kit

Hey Peter,

Hope you got that alox today.

https://i.imgur.com/hziPhBl.png

Inside the spindle box, had to do an extension between the spindle and the cartridge, alternatively I could run it direct drive, but no way to do regular belt drive without compromising the structure of the bridge. I really want the bridge to carry most of the motor weight as close to the middle of it as possible.

I'm not sure about the extension though, particularly the bearing config https://i.imgur.com/9xzCViQ.png

-

02-23-2021, 09:03 PM #835

Member

Member

- Join Date

- Jul 2018

- Posts

- 6341

Re: Milli a new composite mill kit

Hi All - waiting for ALOx looks like today. In the mean time I've been playing with the laser. Up to getting the CAD/CAM to talk to it. But I pushed two buttons in sequence trying to do something and it "reset" it cleared the memory of the machine!! Bummer. Now I'll have to figure how to set up the machine variables from scratch with no documents. The ARGUS mountain just got a little taller... Peter

-

02-23-2021, 11:26 PM #836

- Join Date

- Mar 2020

- Posts

- 179

-

02-27-2021, 10:47 AM #837

Member

Member

- Join Date

- Jul 2018

- Posts

- 6341

Re: Milli a new composite mill kit

Hi All - Been away for a couple of days. ALOX now in stock may do the first test tomorrow.. Peter

-

02-27-2021, 05:45 PM #838

Member

Member

- Join Date

- Nov 2020

- Posts

- 361

Re: Milli a new composite mill kit

Here's a cool picture about UHPC inserts.

-

02-27-2021, 09:32 PM #839

Member

Member

- Join Date

- Jul 2018

- Posts

- 6341

Re: Milli a new composite mill kit

Hi Ard - Thanks Sudholt-Wasemannn have a lot of info about UHPC on their site.. Got home yesterday from a shirt trip and my main computer didn't boot!! Seems it liked the rest so much its staying cold... So its off to the tech tomorrow. Can't use my CAD system so I'm forced to do some ALOX casting....

Peter

Peter

-

02-27-2021, 11:38 PM #840

Member

Member

- Join Date

- Nov 2020

- Posts

- 361

Re: Milli a new composite mill kit

Hey good to hear from you, I was wondering whether one of the outback beasts ate you or something...

Actually that data is direct copy from durcrete, here's the original repository:

https://durcrete.de/downloads-english/?lang=en

Similar Threads

-

WillMill - HSM Benchtop Composite Mill

By Williamlii in forum CNC Wood Router Project LogReplies: 56Last Post: 05-31-2020, 07:03 AM -

Creating 3D model to mill molds for a composite RC glider

By Snowy in forum Hobby DiscussionReplies: 1Last Post: 07-11-2018, 04:14 AM -

Composite Mini Benchtop Mill / Router

By ficklecycler in forum Benchtop MachinesReplies: 10Last Post: 06-01-2018, 12:22 PM -

Looking for some composite routing

By Locster13 in forum DIY CNC Router Table MachinesReplies: 3Last Post: 11-02-2006, 05:20 PM

Reply With Quote

Reply With Quote