This is our first real run of something with our new machine. It took 20 hours for the roughing pass then another 40 for the finishing pass. Mainly due to me not getting the correct tool before I started. (I'm still learning :idea: ) I drew the solid model in VectorWorks, wrote the program using Bobcam and used DeskCNC to run it.

It will be turned into a fiberglass mold.

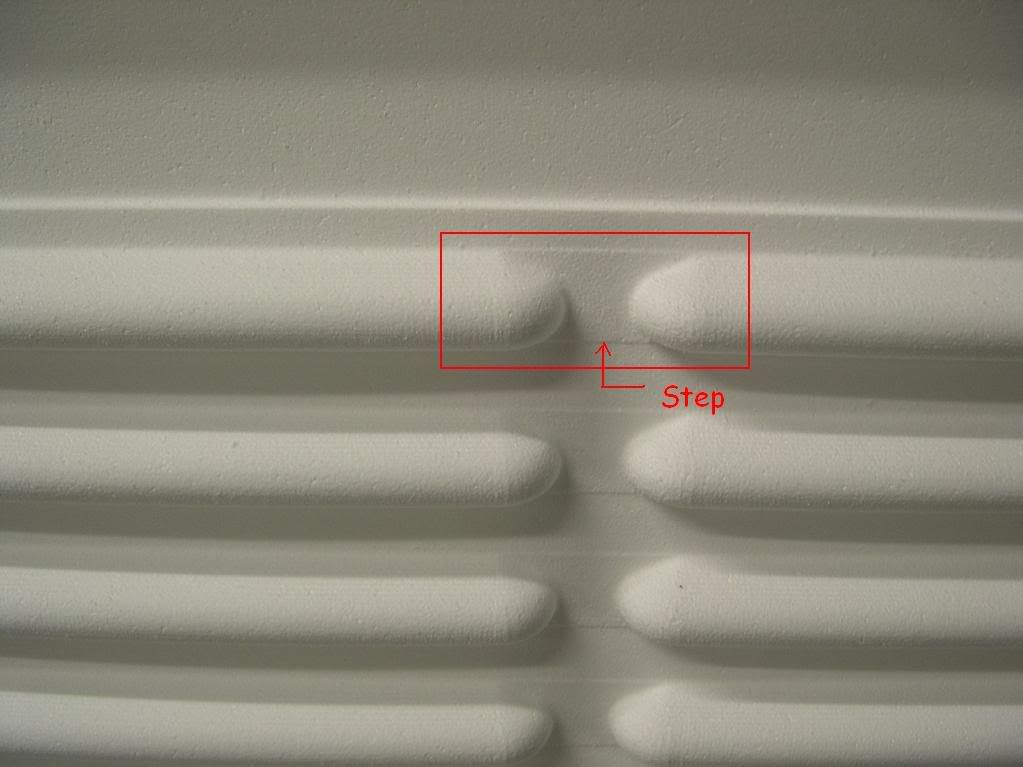

They're venting louvers if you're wondering WTH it is.

There was a F-up with the finishing pass though. I don't know why BobCam put that step there.

Next project............A Snake

Thread: Here's 60+ hours of work....

Results 1 to 17 of 17

Hybrid View

-

10-18-2007, 02:08 PM #1

Registered

Registered

- Join Date

- Sep 2007

- Posts

- 34

Here's 60+ hours of work....

-

10-18-2007, 02:44 PM #2

Gold Member

Gold Member

- Join Date

- May 2005

- Posts

- 1810

Nice!

ScottConsistency is a good thing....unless you're consistently an idiot.

-

10-18-2007, 06:11 PM #3

Registered

Registered

- Join Date

- Mar 2005

- Posts

- 103

I don't see anything...

-

10-19-2007, 03:14 AM #4

what is magazine from?

-

10-19-2007, 11:54 AM #5

Registered

Registered

- Join Date

- Sep 2007

- Posts

- 34

-

10-22-2007, 06:28 AM #6

Member

Member

- Join Date

- Apr 2007

- Posts

- 1955

Hi - nice work. I am toying with doing some foam routing for a hobby project with my 10 yr old son.

Is that just plain old home depot styrofoam providing that nice surface, or are you using some type of specific lbs / cu ft stuff ?

Did you find some router bits that work "better / faster"? I am toying with using either just plain wood bits, or I am also looking at some end mills for cutting Al. Suggestions ?

Thanks

-

10-22-2007, 12:01 PM #7

Registered

Registered

- Join Date

- Sep 2007

- Posts

- 34

-

10-22-2007, 06:39 AM #8

Member

Member

- Join Date

- Oct 2005

- Posts

- 4230

you say your going to turn it into a fibreglass mold , are you going to apply the resin directly to the foam ? reason i ask is ive often wondered if the resin would eat thru it like gas does , its something ive been meaning to test but haven t got around to it

-

10-22-2007, 11:58 AM #9

Registered

Registered

- Join Date

- Sep 2007

- Posts

- 34

-

10-25-2007, 12:04 PM #10

Registered

Registered

- Join Date

- Oct 2007

- Posts

- 3

polyester resin will eat it, as well as vinylester. However, you can coat it with epoxy. White, blue, and pink foams are all "melted" by polyester based resins. Urethane foams can be used with any resin. If it were me, I would hard coat it in epoxy, then run it through another pass on the router.

-

10-26-2007, 12:34 PM #11

Registered

Registered

- Join Date

- Jan 2007

- Posts

- 19

Foam Covered With Glass Fiber

Foam Covered With Glass Fiber

Many things are built using foam covered with glass. All composite air craft are built this way. I have built many pieces this way. It very imortant to use the proper foam and liquid. Though I haven't built parts vacumn bagging the glass to the foam.

LeeThe more you know teaches you don't know alot

-

10-26-2007, 12:35 PM #12

Registered

Registered

- Join Date

- Sep 2007

- Posts

- 34

-

10-26-2007, 03:40 PM #13

Registered

Registered

- Join Date

- Oct 2007

- Posts

- 3

Do you mind if I ask what you are coating it with?

Composites fabricator.

-

10-26-2007, 06:29 PM #14

Registered

Registered

- Join Date

- Sep 2007

- Posts

- 34

-

10-27-2007, 12:52 AM #15

Member

Member

- Join Date

- Dec 2005

- Posts

- 1408

Dear ajinjax.

I cannot possibly claim to be an expert, but surfboard shapers use polyurethane foam blanks, not styrofoam ones. PU is not eaten away by polyester and styrene. My guess is that even if you coat your polystyrene foam with a coat of something, there may be a few tiny pin-holes, if you are unlucky.

Polyester resin will eat into it as fast as the "Alien's" blood went through the bulkheads of the Nostromo in the first film.

My two cents.. and good luck anyway.

best wishes,

Martin

-

10-27-2007, 01:30 PM #16

Member

Member

- Join Date

- Jul 2003

- Posts

- 1220

[QUOTE ajinjax #1]

There was a F-up with the finishing pass though. I don't know why BobCam put that step there.

Re your other post:

http://www.cnczone.com/forums/showthread.php?t=45437

I understand it was proven that the BCC tool path was not the problem.

-

10-27-2007, 04:52 PM #17

Member

Member

- Join Date

- Apr 2007

- Posts

- 1955

Please keep posting your parts projects as you go along - esp. the mistakes. My focus is just hobby, and by the time I get my machine running, I will have learned a ton from your work. - Thanks

Similar Threads

-

How do you tell hours on haas vfo?

By turboboy in forum Haas MillsReplies: 6Last Post: 05-25-2022, 08:46 PM -

CNC Hours?

By end-mill in forum Haas MillsReplies: 3Last Post: 09-05-2007, 03:38 AM -

On time Hours

By smittys800 in forum Haas MillsReplies: 5Last Post: 08-27-2007, 05:56 AM -

how many hours is a lot?

By 1ctoolfool in forum Haas MillsReplies: 2Last Post: 04-30-2007, 11:34 AM -

3 hours on the machine, or....

By Twistr in forum News AnnouncementsReplies: 8Last Post: 06-08-2005, 11:20 PM

Reply With Quote

Reply With Quote