First off let me introduce my self, my name is Marq and I am a undergraduate at the University of Utah. I am studying mechanical engineering and work at the schools advanced manufacturing lab where we machine just about everything.

I have come across an old waterjet cutting machine at school and they have agreed to give it to me in exchange for getting rid of itHere are some pics of the beast (it is the one in front, not the injection press)

The setup has 2 stepper motors:

-Vexta 2-phase, 1.8*/step, 4 amp, 0.75 ohm, model number PH299-E4.0

-ISEL-Automation 2-phase, 1.8*/step, 2.8v, 2.8 amp (uni), 4 amp (bi), model number 473030

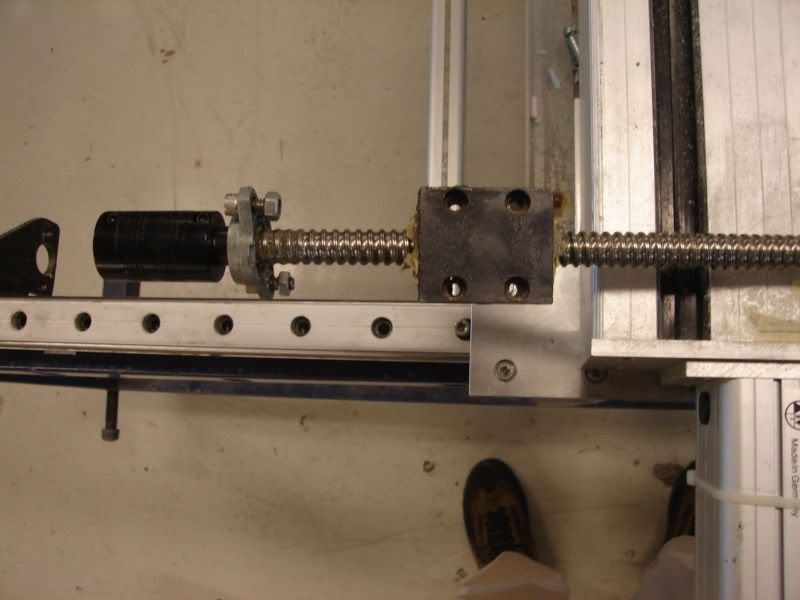

-The machine also had two 6.5 foot linear bearings with 4 pillow blocks

and a 5.5 foot long ball screw

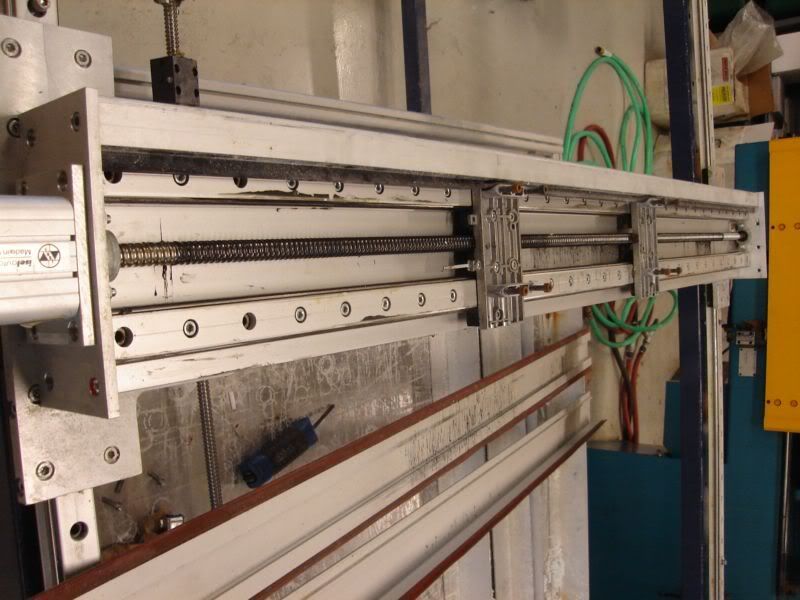

-A super nice enclosed y-axis (4 ft 10 in long)

The machine was originally a 2-axis machine, but with the size of it I am sure I can turn it into a nice sized 3-axis.

I have been looking into HobbyCNC's stepper motor controllers and would like to order one soon. Do you think it will handle the motors that I have?

I will keep you guys updated as I find stuff out:idea:

-Marq

Thread: 3-axis router project

Results 1 to 17 of 17

-

12-13-2007, 10:27 PM #1

Registered

Registered

- Join Date

- Dec 2007

- Posts

- 13

3-axis router project

-

12-16-2007, 05:42 PM #2

Registered

Registered

- Join Date

- May 2003

- Posts

- 323

Sir,

Looks like you have quite a catch! Probably the most common source for stepper drivers is the Gecko units. many people use them and speak highly of them. The Hobby units are for ssmall systems. You will need more current and more voltage (for speed).

Lookup the specs on your steppers to see what turque you have and particularly get the speed-torque curve, as the available torque drops off as speed increases. This will let you plan your max speed. Also be aware of the "critical speed" which is a factor in using ballscrews. The manufacturer will show this.

What will be your final results with this jewel?

Regards,

Jack C.

EE., Class of '57, U of Wisconsin

-

12-18-2007, 07:38 PM #3

Registered

Registered

- Join Date

- Nov 2007

- Posts

- 197

wow thats an amazing find!

good luck with the project. you are 75% there

-

12-19-2007, 04:12 AM #4

Registered

Registered

- Join Date

- Dec 2007

- Posts

- 13

Looking into the motors, I got one of the companies to email me the spec sheet.

I also found this link on the other motor, they list it as having 110 Ncm torque output.

http://www.cvtech.com.au/automation/smotor.htm

My goal with the machine is to have a decent sized router that can make circuit boards, do some light duty alumn jobs, and wood. I would like to get the gecko unit but don't think I can afford to by three units at $150. Each unit only does 1 axis right?

I did some more looking into controllers and the Xylotex unit look decent for the price. I do want to run the motors bipolar, and this unit seems to fit my budget. How does this unit compare to the geckos?

Thanks guys

-Marq

-

12-19-2007, 06:10 PM #5

Registered

Registered

- Join Date

- Aug 2006

- Posts

- 102

i have both the geckos, & the xylotex. the xylotex is fine for small machines. that is because you are limited to something like 30 volts. at 24 or 28 volts that come with the xylotex kit you do not have the torque for high speed wich is ok if you are not movieng very far. if you disconnect a drive [motor] while the power is on you burn up the bob & drives. it cost $60.00 min for the guy to look & maybe fix your board. since learing more about cnc i will not ever use a bob & drives all in one. because if something happens you have to replace the hole thing!!

the geckos are more expensive but if you get the 203s there is not much you can do to hurt them other than blowing a fuse. that said you can run up to 20 times the rated voltage or 80 volt max. with 20 times rated voltage you can turn the motors a lot faster & have some torgue at high rpm,s. hope this helps. greg

-

12-22-2007, 10:10 PM #6

Registered

Registered

- Join Date

- Dec 2007

- Posts

- 13

So I am really starting to look at the Gecko units and am wondering what kind of power supply I will need? Most of the high voltage power supplies I found were only putting out less than an amp, and the ones that could output more than a few amps are really expensive. I realize that when you drop the voltage through the controller the amperage goes up, but am unsure what I should be looking for.

Also are there some good kits that I can build myself to bring the cost down?

Thanks for the suggestions

-Marq

-

12-23-2007, 12:11 AM #7

Member

Member

- Join Date

- Oct 2005

- Posts

- 4230

keep an eye on ebay and look up power-one , those are very expensive solid supplies and they come up quite regularly and are normally cheap

ive got three power-one 24v - 12a supplies and they can be run series or parallel , those ph299 motors will run well with 24v ,my z axis is a vexta motor similar to yours and it runs about 150 imp at 24v

xylotex can t handle that amperage

youve got a great start there ,it would be worth splurging on the gecko's ,i did a lot of research when i got into the larger sized motors , and honestly for the amperage you need you won t find anything cheaper than gecko that would be trust worthy ,A poet knows no boundary yet he is bound to the boundaries of ones own mind !! ........

-

12-23-2007, 01:27 AM #8

Community Moderator

Community Moderator

- Join Date

- Mar 2003

- Posts

- 35538

Gerry

UCCNC 2017 Screenset

http://www.thecncwoodworker.com/2017.html

Mach3 2010 Screenset

http://www.thecncwoodworker.com/2010.html

JointCAM - CNC Dovetails & Box Joints

http://www.g-forcecnc.com/jointcam.html

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

12-23-2007, 05:20 PM #9

Registered

Registered

- Join Date

- Apr 2007

- Posts

- 323

i read this post the other day..and was gonna post a question about disconecting a drive while under power(a bad idea generally) so after that post ill ask it any way...you can actually disconect a gecko drive with out it going POOF!!! ??? and when you say "geckos 202 and 203 are the only drive" ..is that the only gecko drives ..or the only stepper drives made that you know of ??(dont wanna name any other drives) geckos are mega expensive but if you can (acidentally disconect) em with out em going poof that sounds like a major advantage!!

"witty comment"

-

12-23-2007, 08:18 PM #10

Community Moderator

Community Moderator

- Join Date

- Mar 2003

- Posts

- 35538

The only stepper drives that I know of. And after re-reading the G202 manual, I don't think you can disconnect a motor under power on that drive either, although it does offer short circuit protection for miswired motors.

So, the bottom line is that the G203 is the only stepper drive that I know of that won't die if you disconnect a motor under power.Gerry

UCCNC 2017 Screenset

http://www.thecncwoodworker.com/2017.html

Mach3 2010 Screenset

http://www.thecncwoodworker.com/2010.html

JointCAM - CNC Dovetails & Box Joints

http://www.g-forcecnc.com/jointcam.html

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

12-23-2007, 08:41 PM #11

Registered

Registered

- Join Date

- Dec 2007

- Posts

- 13

Another question for you guys, do you know what type of linear bearings those are (pic is in my first post)? I might need some more pillow blocks and was wondering where I might find them?

-

12-24-2007, 04:26 AM #12

Registered

Registered

- Join Date

- Apr 2007

- Posts

- 323

well actually turbogt i was gonna ask you what they were.

..i was wondering what the trucks look like (pillowblocks) on the inside are they a bushing or are they bearings..any way you can get us a picture i dought i could help you much... ger might ..i was just wondering what they look like where the rails ride on looks like two round bars ..but i cant tell if they have v-groove bearings or what to roll on...or if they simply glide on a bushing maybe brass or something..but dont dissassemble them if you think they might fall apart...they maybe tricky to put back together..but with that in mind if you could get a close up of the part that slides on the two round bars ..which are on the rails...id like to see em...thanks...sry i got no answers for ya turbogt...

"witty comment"

..i was wondering what the trucks look like (pillowblocks) on the inside are they a bushing or are they bearings..any way you can get us a picture i dought i could help you much... ger might ..i was just wondering what they look like where the rails ride on looks like two round bars ..but i cant tell if they have v-groove bearings or what to roll on...or if they simply glide on a bushing maybe brass or something..but dont dissassemble them if you think they might fall apart...they maybe tricky to put back together..but with that in mind if you could get a close up of the part that slides on the two round bars ..which are on the rails...id like to see em...thanks...sry i got no answers for ya turbogt...

"witty comment"

-

12-24-2007, 01:21 PM #13

Community Moderator

Community Moderator

- Join Date

- Mar 2003

- Posts

- 35538

They look like these.

http://www.lm76.com/speed_rail_osg.htmGerry

UCCNC 2017 Screenset

http://www.thecncwoodworker.com/2017.html

Mach3 2010 Screenset

http://www.thecncwoodworker.com/2010.html

JointCAM - CNC Dovetails & Box Joints

http://www.g-forcecnc.com/jointcam.html

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

12-24-2007, 10:00 PM #14

Registered

Registered

- Join Date

- Dec 2007

- Posts

- 13

I dont have the machine at home yet, so I will take some pics next time I am up there.

I have been looking at the power-one power supplies and was wondering if I want higher voltage with less amperage or lower voltage and more amperage? I have found 2 units that I am looking at and one has a high output of 48 volts and 16 amps and the other has 28 volts and 27 amps. Also some of these units have several outputs on them i.e. 5V, 12V, 24V, and 48V can I run these units in series with themselves?

Thanks guys

Marq

-

12-25-2007, 12:27 AM #15

Member

Member

- Join Date

- Oct 2005

- Posts

- 4230

either the 24v or the 48v will be plenty of power , at 48v you have pretty much double the speed than you would at 24v , i'd go for the 48v

A poet knows no boundary yet he is bound to the boundaries of ones own mind !! ........

-

12-27-2007, 03:50 AM #16

Registered

Registered

- Join Date

- Dec 2007

- Posts

- 13

I have found the bearing manufacture ..... they are made my Isel. They are their series 1 bearings and can be found here:

http://www.techno-isel.com/lmc/Products/iselrail1.htm

Now I need to get designing this thing :cheers:

-

12-28-2007, 03:42 AM #17

Registered

Registered

- Join Date

- Apr 2007

- Posts

- 323

ahhh....i see ..so they do use v-groove bearings...man im likeing those v-groove bearings better all the time

if i dont build my own bearing blocks (out-ta alum running on flat ground stock) ill have to use v-groove bearings ive seen a few people using those and they look like just the thing i can mill some chamfers on some steel bar and use em or like the rails you have...(im really going on about those bearings aint i??

if i dont build my own bearing blocks (out-ta alum running on flat ground stock) ill have to use v-groove bearings ive seen a few people using those and they look like just the thing i can mill some chamfers on some steel bar and use em or like the rails you have...(im really going on about those bearings aint i??

) looking foward to seeing some designs on your machine

) looking foward to seeing some designs on your machine

...thanks for the info ger21 and turbogt !!"witty comment"

Similar Threads

-

Another new router project

By acondit in forum CNC Wood Router Project LogReplies: 144Last Post: 07-30-2009, 12:09 AM -

large(ish) 5-axis router project

By vwdevotee in forum DIY CNC Router Table MachinesReplies: 34Last Post: 10-30-2007, 12:04 PM -

CNC Router Project 24²

By BoxGods in forum DIY CNC Router Table MachinesReplies: 17Last Post: 01-03-2007, 06:53 AM -

My router project

By twombo in forum DIY CNC Router Table MachinesReplies: 26Last Post: 11-05-2004, 11:07 PM -

Another Router Project

By pminmo in forum DIY CNC Router Table MachinesReplies: 12Last Post: 12-25-2003, 12:26 PM

Reply With Quote

Reply With Quote