Hey All, I really like what you'll do here. The creations are fantasic and Im thinking I should make my own CNC one of these days. I've got lots of projects that could use a good flat bed CNC router. Here some pics of my last project.

As my user name suggests Im a bit of a costumer. Making spidey suits has been a hobby of mine for the past few years but I'm now branching out into other areas and feel a CNC would come in pretty handy.

For my last project I used a milling machine to produce the webbing for my spidey costume. Here are some pics.

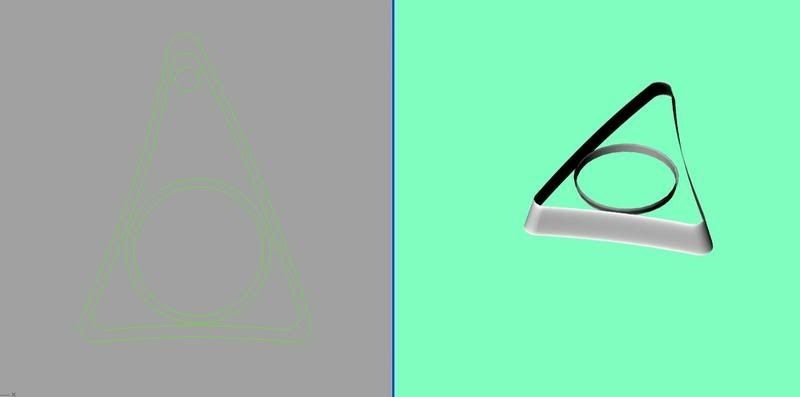

My next project requires a little less work on the CNC but still could use a good clean master that I can mould in Urethane.

Here's a look at the original... my CAD drawing... Oh.. and a pic of my suit to date.

The cape clip basically holds the cape and cowl (Mask) in place. I thought about making it in clay and making a mould in silicon to cast the final product in urethane, but my clay skills are pretty poor. Best leave in to computer.

6mm Aluminum should do the job nicely.

Brad.

Thread: Spidey Costume

Results 1 to 20 of 81

-

02-10-2008, 03:18 PM #1

Spidey Costume

www.spidey4fun.com

-

02-10-2008, 04:17 PM #2

Member

Member

- Join Date

- Apr 2005

- Posts

- 3634

Looks Great!

Do you make the entire suit, other than the molded parts?

That's all my boy wanted for last christmas was the black spidey stuff (anything).

Thanks for posting.

.Free DXF - vectorink.com

-

02-11-2008, 12:30 AM #3

Registered

Registered

- Join Date

- Jul 2006

- Posts

- 1062

I was hesitant to look at first...Glad I did lol great idea and method!

Keith

-

02-11-2008, 02:03 AM #4www.spidey4fun.com

-

02-11-2008, 03:07 AM #5

Registered

Registered

- Join Date

- Jan 2007

- Posts

- 355

Beautiful work, Brad.

I've been a Spider-Man fan since I was 7 years old. In 1963.

I don't think that Peter Parker used your amazing technique to make his suit, but I'm sure he would approve.

By the way, is the Batman utility belt functional ?

-

02-11-2008, 03:17 AM #6

A Batman utility belt functional...

Now that would be a challange for you guys who own a CNC.... unfortunately mine is just made of resin and flexible urethane. BUT... I'd like a more fuctional belt. Maybe.. a metal belt with containers that actually open... and a belt that could carry a 92 kgs (200lbs) weight. Putting a motorised winch / winder in the front of it maybe a bit much. But still... sounds pretty cool. And of course it would need to have the exact some look / style. Batman's got lots of cool toys. Im sure he'd have a CNC at his disposal.

www.spidey4fun.com

Batman's got lots of cool toys. Im sure he'd have a CNC at his disposal.

www.spidey4fun.com

-

03-05-2008, 06:34 AM #7

Milling Wax

I've put my CNC together and just ordered my Mach3 licence. Now I'm looking for some milling wax. Can anyone provide any assistance as to where I may find some in Australia?

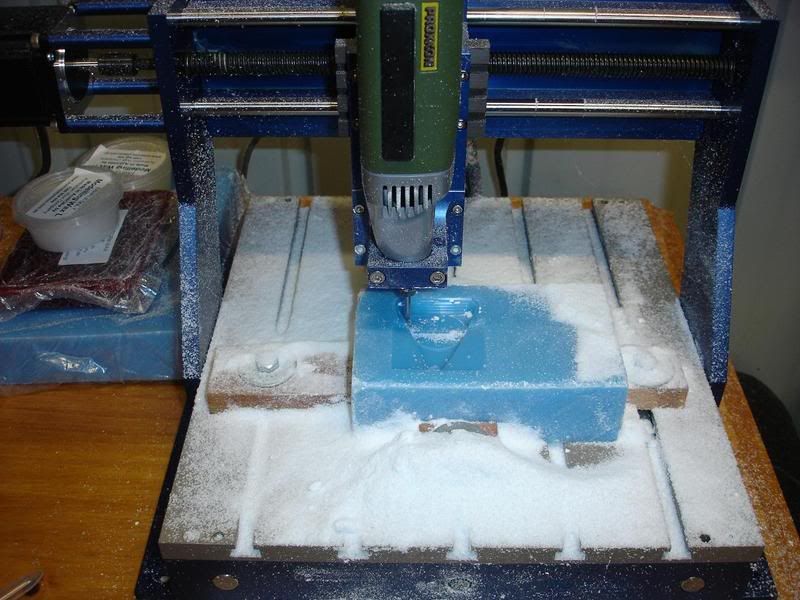

Here's my CNC.

www.spidey4fun.com

www.spidey4fun.com

-

03-05-2008, 11:07 PM #8

Registered

Registered

- Join Date

- Jan 2007

- Posts

- 355

Brad,

You can't just post a photo of your router with no details!

Tell us about it...Diplomacy is the art of saying "Nice doggie" until you can find a rock. - Will Rogers

-

03-06-2008, 09:44 AM #9

LOL... sure I can. I just did. But OK... since you asked so nicely.

Weight: 21.5 Lbs

X-Axis travel: 8.250" (209.5500 mm)

Y-Axis travel: 9.125" (231.7750 mm)

Z-Axis travel: 3.900" (99.0600 mm)

T-Slot Plate Width: 11.250" (285.750 mm)

T-Slot Plate Length: 12.000" (304.8000 mm)

Opening Under Gantry" 3.900" (99.0600 mm)

Height: 11.45" (290.83 mm)

Width: 13.2" (335.28 mm)

Length: 12.50" (317.5 mm

Made in the US of A.

Proxxon for the cutter and Xylotex driver card and 4 stepper motors. I thought I'd get the extra as a spare. A very net little unit.

www.spidey4fun.com

www.spidey4fun.com

-

05-08-2008, 09:57 AM #10

I finially found some time.. or made some.. to give the CNC a try. Thought I try something simple like a cape clip. So here are some pics of the mold being made. I'll use resin to make a master, then do some fine sanding to remove the machine marks...then I could cast a master silicon mold.

The process should lend itself to making all sorts of cool stuff. But Im still learning.

www.spidey4fun.com

www.spidey4fun.com

-

05-08-2008, 10:52 AM #11

I forgot to add...... the wax makes a real mess. Does anyone have any good ideas how to make a small vacuum system. The wax almost floats on air so I figure a small computer fan would move it... but I'd like a dyson vacuum type set-up so I could collect the wax in a chamber, melt it down and make another wax block.

Any ideas????www.spidey4fun.com

-

05-08-2008, 11:22 AM #12

Registered

Registered

- Join Date

- May 2006

- Posts

- 1469

Glad to see some activity there Brad.

Are you coming to the BBQ?

Greg

-

05-08-2008, 11:26 AM #13

Hey Greg... better email me the where and when.

I'll see what Im doing.

I wonder if this would work..

http://cgi.ebay.com.au/NEW-USB-Mini-...QQcmdZViewItem

Cheers

Bradwww.spidey4fun.com

-

05-08-2008, 11:45 AM #14

Registered

Registered

- Join Date

- May 2006

- Posts

- 1469

Brad see this link for info

http://www.cnczone.com/forums/showthread.php?t=53559

-

05-08-2008, 02:09 PM #15

So here's my first test. Cut with a 1/32 inch bit. I'm guessing it will finish better with a 1/64. Also needs to be cast in resin so the side slots can be cut.

But all in all I'm happy with the first test. Sorry for out of focus.. was too close for the camera.

www.spidey4fun.com

www.spidey4fun.com

-

05-09-2008, 09:33 AM #16

Community Moderator

Community Moderator

- Join Date

- Feb 2004

- Posts

- 2337

Hey I missed this thread. Good $hit Brad.

You might be interested that I am currently building a vaccuum forming machine 700 x 1200 sheet size. If you wanted to make any body amour bits out of MDF I could vac form them for you. Keep up the good work and keep posting.

Regards BennyBeing outside the square !!!

-

05-09-2008, 09:38 AM #17

Oh yeah... Im interested. This is one of the tools most guys seem to have in their workshops. This might be of interest to you.

http://www.studiocreations.com/howto...per/index.html

Brad.www.spidey4fun.com

-

05-09-2008, 09:49 AM #18

Community Moderator

Community Moderator

- Join Date

- Feb 2004

- Posts

- 2337

I have seen that storm trooper amour is a popular vac forming task before.

What ever parts you design on your router or however, I will cast at materials cost price for you. Up until you start selling them, then we can negotiate a deal if you want.Being outside the square !!!

-

05-09-2008, 10:04 AM #19

-

05-09-2008, 10:31 AM #20

Community Moderator

Community Moderator

- Join Date

- Feb 2004

- Posts

- 2337

Looks like you are going to put that wigitmaster to a lot of work making molds.

Being outside the square !!!

Similar Threads

-

'spidey' Scales Heights

By WallCrawler in forum Community Club HouseReplies: 0Last Post: 08-05-2004, 01:47 PM

Reply With Quote

Reply With Quote