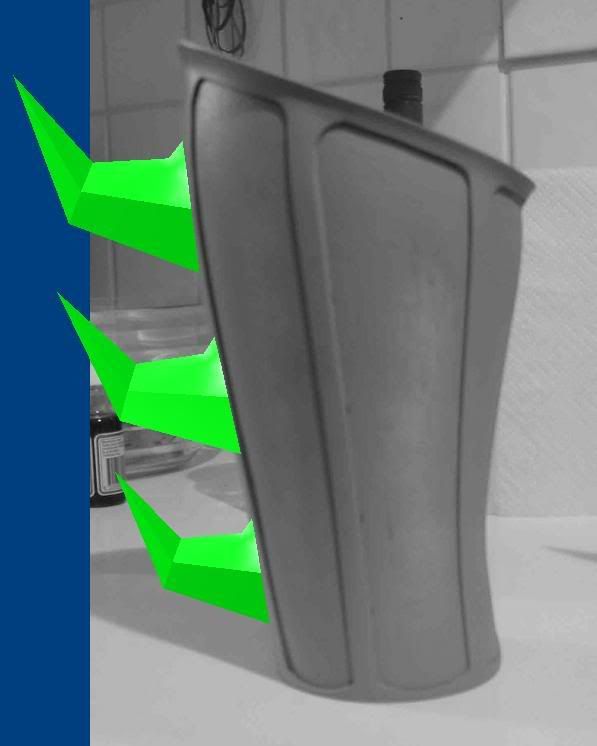

I thought I'd try the centre of the belt I drew.

Might make another. Just need to change the scale of a few things.

Thread: Spidey Costume

Results 21 to 40 of 81

-

05-10-2008, 05:32 PM #21www.spidey4fun.com

-

05-19-2008, 10:27 AM #22

More pics of things Im making......

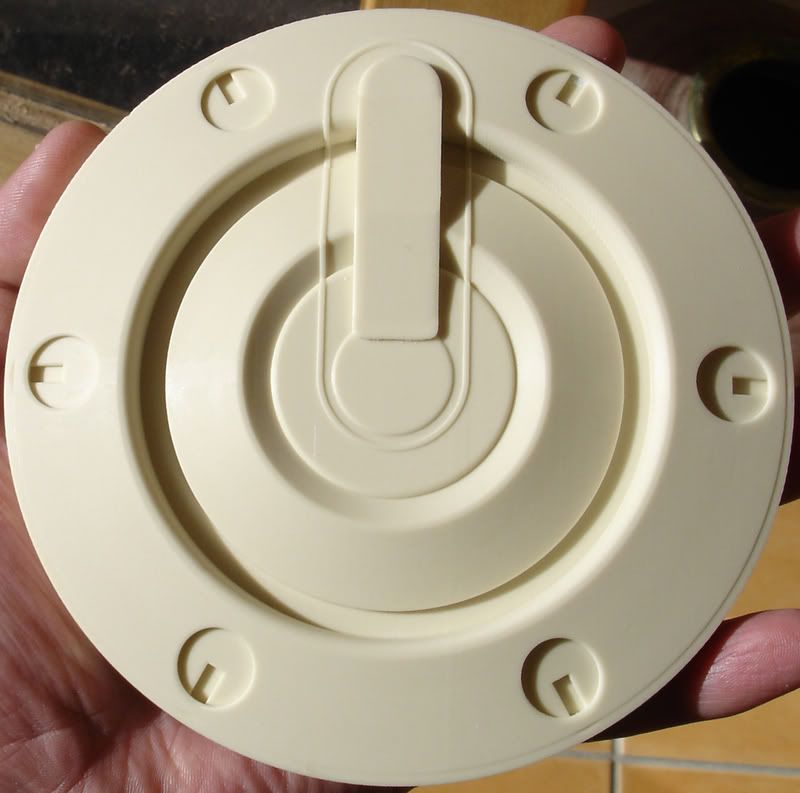

Molds for fins....I made 1 as a test..

Then I thought I try all three. This is only 1/2 the mold.

And the finished product will look something like this..

Brad.www.spidey4fun.com

-

05-26-2008, 10:15 AM #23

Has anybody got any Vexta Clean Dampers D6CL-6.3 going? I need 3. Oh... And I got paypal $$.

Cheers

Brad.www.spidey4fun.com

-

06-04-2008, 02:05 AM #24

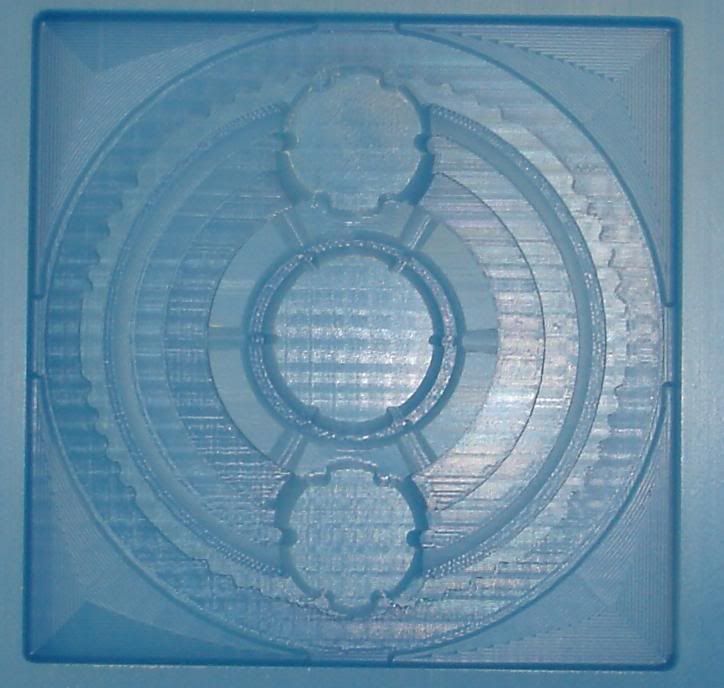

Another part.. the hip mold of this costume.

www.spidey4fun.com

www.spidey4fun.com

-

06-04-2008, 03:01 AM #25

Community Moderator

Community Moderator

- Join Date

- Feb 2004

- Posts

- 2337

Hey Brad, I notice you are making negative molds. What would happen if you made it as positive and used silicon to make the negative mold?

The other question is, can the wax be remelted and used again?Being outside the square !!!

-

06-04-2008, 03:00 PM #26

Hey Ben,

I'm making the part for a guy in the UK and he's got plenty of moulding skills but just thought it would be easier and more accurate to have it cut on CNC. So the easiest thing for me to do is cut a negative...fill it with resin.. pop out a master and ship it off. If / when I get around to needing this part I will most definately cut a positive, like I did for the fins and just cover it with silicon.

Yes... the wax can be melted down and used again. That wax used below was also used to make the belt centre and fins. After I've made the piece I require I just melt it down with the wax dust I collected during the cut and start over.

Brad.www.spidey4fun.com

-

06-04-2008, 11:48 PM #27

Community Moderator

Community Moderator

- Join Date

- Feb 2004

- Posts

- 2337

What is the wax called? Is it expensive? where do you buy it from?

When you remelt it. does it from correctly, or does it have a warping effect like when pouring candles?Being outside the square !!!

-

06-05-2008, 01:26 PM #28

Hey Ben,

www.australianwaxco.com.au It's called engineering wax. The guy you need to speak to is Bill Cassidy. Tell him you've been speaking to Brad in Geelong. Cost $10.67 per kilo $50.15 per slab. Not sure how big a slab is.

I just bought some baking trays and heat it slowly on my electric stove. It does slightly wave on the top but I mill into the base. The slight waves on the top still allow it to sit flat on the CNC table.

Brad.www.spidey4fun.com

-

06-05-2008, 02:19 PM #29

Community Moderator

Community Moderator

- Join Date

- Feb 2004

- Posts

- 2337

Funny, I have actually been to that factory myself. (Kids went through a candle making phase) Is the engineering wax harder than candle wax, as I ow remember I have a slab of candle wax here.

Thanks for the information.

BTW if there was a vote for the best display at the BBQ the other week, I would have picked yours because you demonstrated a lot of uses for your CNC machine.Being outside the square !!!

-

06-05-2008, 10:53 PM #30

Community Moderator

Community Moderator

- Join Date

- Feb 2004

- Posts

- 2337

Here is a short video of Brads machine in action.

http://www.youtube.com/v/ugepIp45HbY&hl=enBeing outside the square !!!

-

06-07-2008, 03:06 AM #31

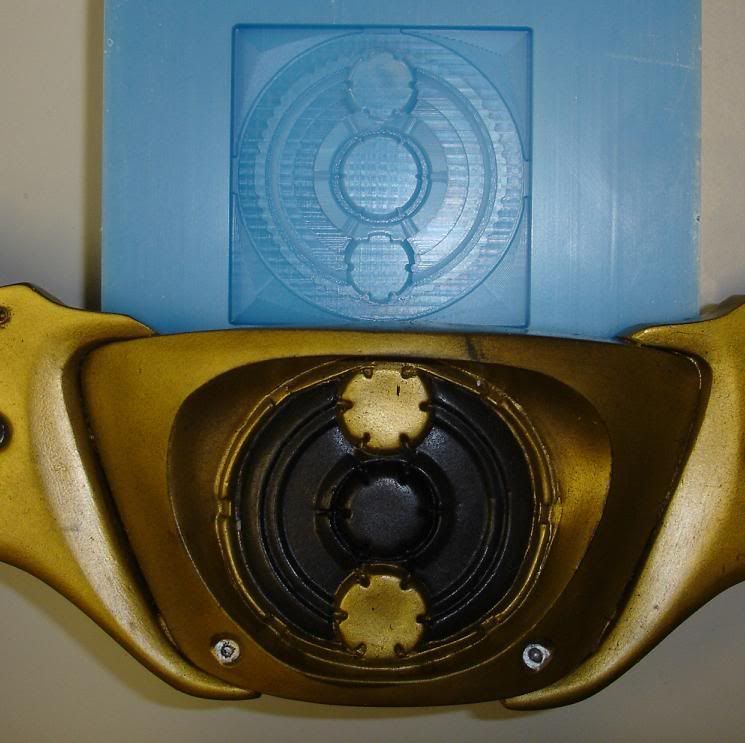

Here's my first attempt at using resin. I'm pretty happy with the results!!

I re-made the mould shown below... made it 2cm smaller and used an STL file for the model. The DXF file didnt look that smooth in the end, but that was probably just the way I saved it.

Brad.www.spidey4fun.com

-

06-07-2008, 03:43 AM #32

Registered

Registered

- Join Date

- May 2006

- Posts

- 1469

That looks to be a pretty good finish on it Brad.

Any steps to achieve that between machining it and moulding the resin?

Greg

-

06-07-2008, 05:11 AM #33

That's straight from the CNC. 1/8 rough cut B/N bit. 1/8 Parrallel finish 10% step. 1/8 Parallel finish 5% step but 90degree from first. And finish with a 1/32 FN bit 10%...which took about 6 hours. The finshed piece is a polyurethane resin.

www.spidey4fun.com

-

06-07-2008, 05:24 AM #34

Registered

Registered

- Join Date

- May 2006

- Posts

- 1469

Wow.... no wonder you got a good finish. 4 passes.

Greg

-

06-07-2008, 10:57 PM #35

Registered

Registered

- Join Date

- Jul 2006

- Posts

- 1062

I'm amazed and hooked by this thread! You're my superhero

:beer: Have a nice cold one on me!

Keith

:beer: Have a nice cold one on me!

Keith

-

06-08-2008, 03:12 PM #36

Registered

Registered

- Join Date

- Jul 2007

- Posts

- 32

You guys are mad!

My build log: http://www.mycncuk.com/forums/showthread.php?t=7

-

06-09-2008, 03:54 AM #37

Community Moderator

Community Moderator

- Join Date

- Feb 2004

- Posts

- 2337

Brilliant job Brad. !!!

Not all of us dress as super heros,You guys are mad! ,but its interesting and admirable to see a member use his talents to pursue his hobby in such a skilled way. Keep it up Brad.

Being outside the square !!!

,but its interesting and admirable to see a member use his talents to pursue his hobby in such a skilled way. Keep it up Brad.

Being outside the square !!!

-

06-10-2008, 11:55 AM #38

-

09-02-2008, 12:01 PM #39

Im just about to start my new machine. This time it'll be built .... well mostly. 1500mm x 1000mm x 600mm. 4 x 16mm ballscrews and SBR linear bearing and rails. Im thinking geckos with stepper motors. If anyone has a good lead on stepper motor I'd be interested to hear. I'll post pics as this unit comes together. My little CNC just isnt big enough.

Brad.www.spidey4fun.com

-

09-03-2008, 12:00 AM #40

Registered

Registered

- Join Date

- Jun 2003

- Posts

- 453

Similar Threads

-

'spidey' Scales Heights

By WallCrawler in forum Community Club HouseReplies: 0Last Post: 08-05-2004, 01:47 PM

Reply With Quote

Reply With Quote