I've been trying to think up some ways to hold work pieces down on my cnc table. I'm working mostly with flat stock. Wood or alum. So far the method I have used was a deck screw through the work piece. This is OK if the holes left by the screw are not a problem. This method works good because I can make a perimeter cut all the way around the work piece. The other idea was clamps with Tee nuts in slotwall or something similar. However, this method limits cutting in the areas where the clamps are holding the workpiece. A Vacuum tables may be a solution for flat work pieces. This method would allow perimeter cuts all the way around the work piece. However it may be better for wood than alum.

So I thought it would be good to get a thread going to discuss all the different methods of holding the work.

So what other clamping/holding methods have you used? & How well did it work? Advantages / disadvantages etc. Pics...

Thread: Work Holding Methods

Results 1 to 14 of 14

-

07-27-2004, 04:58 PM #1

Registered

Registered

- Join Date

- Nov 2003

- Posts

- 299

Work Holding Methods

-

07-27-2004, 05:07 PM #2

Registered

Registered

- Join Date

- Apr 2003

- Posts

- 1876

I do vacuum work on alum all the time. Some stuff you wouldn't think would work. Flat stuff is great. I've even come up with a way of milling an outline INSIDE the vacuum area of the fixture without losing vacuum. (most of the time)

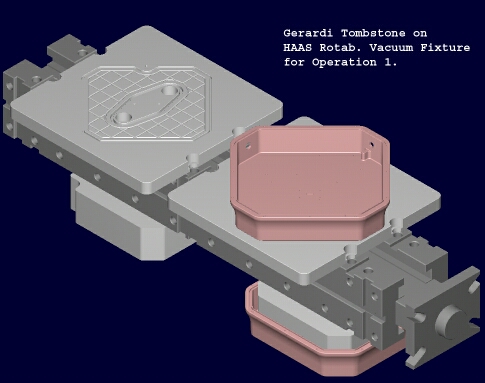

Here's a fixture for some antenna housings I did on vacuum with NO clamps or other work-holding except locating pins. Note there are 2 setups here, the bottom one you can't see as well, but it's also done with vacuum and no other work-holding.

Sky's the limit. I have a 60 gallon dual motor lag/lead system that runs vacuum lines to all 5 machines, including 4 axis tombstones as in the setup shown below.

Matt

Matt

San Diego, Ca

___ o o o_

[l_,[_____],

l---L - □lllllll□-

( )_) ( )_)--)_)

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

07-27-2004, 06:01 PM #3

Banned

Banned

- Join Date

- May 2004

- Posts

- 83

Matt, that's an impressive setup. I've felt for a long time some kinds of machining sucks. Good to see someone put that characteristic to use

-

07-27-2004, 06:57 PM #4

Community Moderator

Community Moderator

- Join Date

- Mar 2003

- Posts

- 35538

Vacuum is definately the way to go. And for doing sheets, it's pretty easy to set up. But for small and odd shaped parts, be prepared to make a lot of jigs and fixtures, ala Rek'd's example above.

Gerry

UCCNC 2017 Screenset

http://www.thecncwoodworker.com/2017.html

Mach3 2010 Screenset

http://www.thecncwoodworker.com/2010.html

JointCAM - CNC Dovetails & Box Joints

http://www.g-forcecnc.com/jointcam.html

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

07-27-2004, 07:56 PM #5

Registered

Registered

- Join Date

- Nov 2003

- Posts

- 634

You could use edge clamps (similar to regular hold down clamps, except they dig into the edge of the wood panel and don't stick up above the part). I think Techno Isel sells them.

Double stick tape, (Carpet tape) works some times.

Matt is showing a dedicated vacuum setup, but you can use a universal grid system with rubber gasketing to avoid needing lots of jigs for odd shapes.

You have to get more creative when cutting small shapes and using vacuum.

T

-

07-27-2004, 11:20 PM #6

Gold Member

Gold Member

- Join Date

- Apr 2003

- Posts

- 598

Has anyone used something akin to "bench dogs" to hold their work piece? There is a new variety designed with a screw clamp, which at least one company calls bench "puppies."

They fit into a hole, and then "adjust" for a perfect fit. Here's a picture from the WoodCraft web site.

Seems like it should hold the work, and not get in the way. (they were designed for use with hand planes)

-- Chuck Knight

-

07-28-2004, 06:50 PM #7

Registered

Registered

- Join Date

- May 2003

- Posts

- 340

Here is a small vac chuck I made recently to hold some magnetic material for machining on a wire EDM, I need to machine three sides of the blanks and clamping tends to break the magnets. It was produced from steel ground flat, a pattern was then put on the steel using the toner transfer method (print on injet photo paper with a laser printer, iron on and soak) and the tracks then etched in ferric cloride. The feed hole in the middle was simply drilled. Works well and could be done on different materials etc, I like the way you can make custom vacuum hold downs with curves etc very easily. The same process could also be done on aluminium with caustic soda (lye, drain cleaner) as the etchant, resist could simply be paint.

Hope this is of some help to someone.

Cheers,

Graham

-

07-29-2004, 01:11 AM #8

Registered

Registered

- Join Date

- Nov 2003

- Posts

- 299

These are some good ideas you guys have come up with. I guess each part has to be approached differently. Lets keep this thread going, I'm sure it could be a big help to have a bunch of methods in one place.

-

07-29-2004, 10:11 AM #9

Registered

Registered

- Join Date

- May 2003

- Posts

- 340

This page is interesting in itself as it shows a guitar being made with CNC, I am not into that but I always find instrument making interesting. It also shows several vacuum hold downs and chucks, several have dual uses by changing the position of the outer gasket:

http://www.frets.com/FRETSPages/Feat...ollings05.html

-

07-29-2004, 10:24 AM #10

Gold Member

Gold Member

- Join Date

- Jan 2004

- Posts

- 353

My contribution>>

The blanks for the fixture start life as 20 mm x 12.7 mm 6061 T6 I then mill these to 9 mm thick and drill a series of holes that line up with the jig.

I bolt 2 x 4mm cap screws into each "part" then contour mill 16 parts at a time, once the contours are done I unbolts the parts and turn the jig over.

I bolt each part into it's slot then mill another contour so the remaining part is 2 mm thick with a 9mm lug sticking out.

I then mill the 9 mm lug to it's profile and cut the large hole (either 10 mm or 12 mm as there are 2 different parts)

I change from the 8 mm end mill to a 3 mm one and mill the radiused slot then remove the finished part from the jig!

If you look at something long enough and think of the forces applied you can usually work out a method to hold it, I really like the vacum table idea and would like to hear more about it such as the pump and so on..

-

07-29-2004, 02:43 PM #11

Registered

Registered

- Join Date

- Jul 2004

- Posts

- 7

Thanks to all who responded to this thread, I end up using following option as in attached image.

1, Routing outer shape from back side

2, Made a small fixture in Nylon

3, clamp those parts in the fixture

4, Cleanup the back face

Eventually everything worked well.

Image link : http://cnczone.com/gallery/data/500/...p-multipcs.jpg

Second option: I had in mind to machine all those parts from back side as shown in first image. Fill up the whole pocket with sand and block the base with another plate so that sand is fully sorrounding those pieces. Then try to machine the front face. I'm not sure if it's going to work but if it does could be good for clamping non uniform shapes.

Good to have vacuum chuck but may not be suitable for small parts.

Thanks

Kevin

-

07-29-2004, 02:55 PM #12

Registered

Registered

- Join Date

- May 2003

- Posts

- 340

Kevin, I think you have replied to the wrong thread, although very relavant to your problem your thread is here:

http://cnczone.com/forums/showthread.php?t=5404

Like the flex fixture clamp thing

Graham

-

07-29-2004, 05:04 PM #13

Registered

Registered

- Join Date

- Jul 2004

- Posts

- 7

Oops! replied to wrong thread, thanks Graham for reminding. That's what happens when you got too many windows open.

Kevin

-

09-14-2004, 09:13 AM #14

Registered

Registered

- Join Date

- Jul 2004

- Posts

- 21

How do you size a vacuum system?

Are there any good sources for vacuum systems(pumps)?

Similar Threads

-

How does a power supply work.

By ynneb in forum DIY CNC Router Table MachinesReplies: 1Last Post: 07-27-2011, 03:40 PM -

What do you use to hold your work down?

By cncadmin in forum Work Fixtures / Hold-Down SolutionsReplies: 2Last Post: 06-03-2005, 04:27 PM -

Work holding????

By anoel in forum Uncategorised MetalWorking MachinesReplies: 17Last Post: 10-14-2004, 06:07 PM -

Looking for additional cutting work. ( Melbourne Australia)

By ynneb in forum Australia, New Zealand Club HouseReplies: 2Last Post: 08-05-2004, 11:53 PM -

What is 2.5 d work

By Patrick2by4 in forum DIY CNC Router Table MachinesReplies: 9Last Post: 07-05-2004, 05:04 PM

Reply With Quote

Reply With Quote