hello

I know this has probably already been covered but for the life of me I can not find it anywhere. How does one square the y and x axis on a cnc machine? My gantry is mounted solid to my tabletop and my y axis is a complete asembly and will pivot so that it can be made square with the gantry. The y axis is a table top and moves independently of the gantry. I will eventualy post pics. I tried using the peg Idea and placing a board on the y axis and drawing a line. Then putting the board on the other side of the pegs and drawing another line. Then measure the distance between and see if the distance is the same.

Next question, what should I paint mdf with. Primer ,enamle or what, does the mdf swell when painted do to absorbing the paint. Does it take a special paint to actually seal the mdf. Could someone point me in the right direction thanks.

Thanks

Shawn

Thread: Square

Results 1 to 9 of 9

-

05-26-2008, 04:15 AM #1

Registered

Registered

- Join Date

- Aug 2007

- Posts

- 4

Square

-

05-26-2008, 05:00 PM #2

Member

Member

- Join Date

- Nov 2006

- Posts

- 152

I've had reasonably good luck with a product called KILZ, usually available in your local hardware or paint store. The problem with mdf is it is wood chips, wax, and resin and the wax tends to bleed through just about everything.

I used to be appalled, now I'm just amused.

-

05-26-2008, 06:22 PM #3

Registered

Registered

- Join Date

- Apr 2003

- Posts

- 307

Latex paints will work fine. That includes water based primers too. What really needs to happen to the MDF is it needs to be sealed first. You can use Kilz as suggested above. Latex primers, oil based primers, shellac all work too. I have even used a mixture of yellow glue and water on the edges to prevent the MDF from soaking up the paint.

On the issue of squaring up your axes; one way would be to draw as large of a square as possible with the machine and then measure the diagonals of the square as accurately as possible.

Another way is to cut 2 identical squares; again larger is better. Then on a flat surface, like your table saw or whatever, reverse one of them and put the edges together. Any error will show up as twice the amount between the two. Theoretically, all you need is a baseline in X and a square cut with the Y. The baseline would sit on the flat surface and the cuts in Y would be put together.

Here is a link to where I asked the same question and then made a test square:

Test square

chris

-

05-26-2008, 11:25 PM #4

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 427

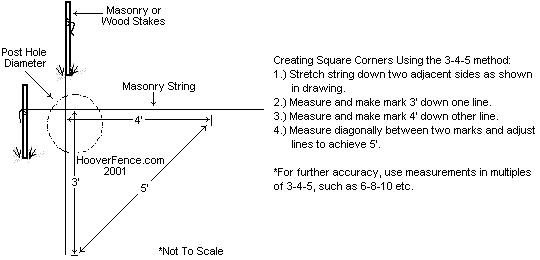

You could use the Pythagorean Theorem, or better known as the 3,4,5 rule to square up your table.

On one side of a corner, measure three inches from the corner and make a mark. On the opposite side of the corner, measure four inches from the corner and make a mark. Next, measure between the two marks. If the distance is five inches, your table is square!

This is scalable. So you could use 6,8,10 inches or 30,40,50 inches. Just a matter of how large you can go on your table.

-

05-26-2008, 11:51 PM #5

Member

Member

- Join Date

- Dec 2005

- Posts

- 1408

Dear hydrogen,

Test squares are well covered by the above. As for sealing MDF, try searching "MDF sucks" on CNCZone threads. Lots of practical advice.... and no definitive answer.

Good luck,

Martin

-

05-27-2008, 12:02 AM #6

Member

Member

- Join Date

- Dec 2005

- Posts

- 1408

Dear Shawn,

Well, I guess I have to get to grips with the relatively new Search function...

http://www.cnczone.com/forums/showth...ight=MDF+sucks

BW,

Martin

-

05-27-2008, 12:12 AM #7

Member

Member

- Join Date

- Oct 2005

- Posts

- 4230

if you use a carpenters square and a finger dial you should be able to get your machine squared to a decent accuracy , you can get a china dial for 20 bucks on ebay which will be good enough to do the job and will assist in future part setups anyhow.

if you dial in the x axis first clamp the square down then you can dial the y axisA poet knows no boundary yet he is bound to the boundaries of ones own mind !! ........

-

05-27-2008, 02:50 PM #8

Registered

Registered

- Join Date

- May 2003

- Posts

- 323

Sir,

Using the approach of Regnar, above, we did the same thing to square the machine, except that we located the (4) corners of the square, then measure the diagonals of the square. The object is to make the diagonals equal. It was relatively easy to get the diagonals within 1/32".

Regards,

Jack C.

-

05-28-2008, 05:39 AM #9

Member

Member

- Join Date

- Oct 2005

- Posts

- 4230

i understand the concept , personally for dead nuts accuracy the machinist in me wouldn t trust anything that wasn t dialed in

,a dial and a square is what i used on mine so i figured i'd throw that out there if anyone was interested:cheers:

A poet knows no boundary yet he is bound to the boundaries of ones own mind !! ........

,a dial and a square is what i used on mine so i figured i'd throw that out there if anyone was interested:cheers:

A poet knows no boundary yet he is bound to the boundaries of ones own mind !! ........

Similar Threads

-

square holes

By JPMach in forum MetalWork DiscussionReplies: 42Last Post: 11-12-2011, 05:29 PM -

Widescreen or square?

By phantomcow2 in forum Uncategorised CAM DiscussionReplies: 9Last Post: 02-28-2011, 12:48 PM -

How square is square and how to get there?

By Roguish in forum Mechanical Calculations/Engineering DesignReplies: 14Last Post: 01-31-2008, 02:16 PM -

square hole?

By 55 dude in forum MetalWork DiscussionReplies: 3Last Post: 03-04-2007, 08:01 PM -

WOn't cut square!

By Ed_R in forum DIY CNC Router Table MachinesReplies: 51Last Post: 03-23-2006, 12:19 PM

Reply With Quote

Reply With Quote